This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

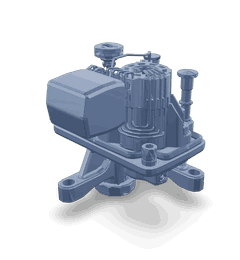

The Cummins 4353197 Doser Injector is a component designed for use in heavy-duty trucks, specifically within the Selective Catalytic Reduction (SCR) system. Its purpose is to inject diesel exhaust fluid (DEF) into the exhaust stream, which plays a role in reducing nitrogen oxides (NOx) emissions. This Cummins part is significant in modern diesel engines as it helps meet stringent environmental regulations by ensuring that emissions are kept within acceptable limits 1.

Basic Concepts of Doser Injectors

A doser injector is a device that precisely delivers DEF into the exhaust stream of a diesel engine. This injection occurs downstream of the engine, where the DEF reacts with NOx in the presence of a catalyst to form harmless nitrogen and water vapor. The doser injector operates in conjunction with the engine control unit (ECU) and other emission control components to maintain optimal DEF dosage rates based on engine load and operating conditions 2.

Purpose of the 4353197 Doser Injector

The 4353197 Doser Injector is integral to the SCR system, where it contributes to the reduction of NOx emissions. By injecting DEF into the exhaust stream, it enables the catalytic converter to effectively neutralize NOx. This process is vital for compliance with environmental regulations, which mandate lower emissions from diesel engines to reduce their environmental impact 3.

Key Features

The 4353197 Doser Injector is characterized by its robust design and construction from high-quality materials, ensuring durability and reliable performance. Technological advancements in this doser injector include precise control over DEF injection timing and quantity, which enhances its efficiency. Unique attributes such as corrosion-resistant materials and advanced sealing technologies contribute to its performance and longevity.

Benefits of Using the 4353197 Doser Injector

Utilizing the 4353197 Doser Injector offers several advantages, including improved emission control, which leads to better air quality. It also enhances engine efficiency by ensuring the SCR system operates within its designed parameters. Compliance with environmental standards is facilitated, which can result in cost savings for fleet operators through avoided penalties and potential incentives for low-emission vehicles.

Installation and Integration

Proper installation of the 4353197 Doser Injector is crucial for its optimal performance. This process involves using the appropriate tools and following specific steps to integrate the injector with the SCR system. Correct installation ensures that the doser injector functions as intended, contributing to effective emission reduction.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the 4353197 Doser Injector. This includes routine checks and inspections to identify and address any issues promptly. Common problems may involve clogging or malfunctions, which can often be resolved through cleaning or adjustments, emphasizing the importance of routine maintenance.

Performance Monitoring

Monitoring the performance of the 4353197 Doser Injector can be achieved through diagnostic tools and techniques. Interpreting data from these tools allows for the early identification of potential problems, enabling timely interventions to maintain the injector’s efficiency and the overall effectiveness of the emission control system.

Environmental Impact

The use of the 4353197 Doser Injector contributes to reduced emissions, aligning with regulatory standards aimed at minimizing the environmental impact of diesel engines. Advanced doser injectors play a role in promoting sustainable transportation by ensuring that vehicles operate with lower emissions, supporting efforts towards a cleaner environment.

Cummins Corporation

Cummins Inc. is a leader in the automotive industry, known for its commitment to innovation and environmental responsibility. The company has a history of developing advanced emission control technologies, including the 4353197 Doser Injector, which reflects its dedication to improving the efficiency and environmental performance of diesel engines.

Compatibility with Cummins Engines

The Doser Injector part number 4353197, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is crucial for ensuring the precise delivery of DEF, which is essential for the optimal performance and efficiency of the engines.

QSG12/X12 CM2350 G110

The Doser Injector 4353197 is compatible with the QSG12/X12 CM2350 G110 engine. This engine is known for its robust design and reliable performance, making it suitable for various applications. The doser injector ensures that the DEF is delivered in the correct proportions, enhancing the engine’s efficiency and reducing emissions.

QSK19 CM2350 K105 and QSK19 CM2350 K114

The Doser Injector 4353197 is also compatible with the QSK19 CM2350 K105 and QSK19 CM2350 K114 engines. These engines are part of the QSK19 series, which is renowned for its power and durability. The doser injector plays a vital role in maintaining the balance of DEF delivery, ensuring that these engines operate at peak performance levels.

QSK50 CM2350 K108

The Doser Injector 4353197 fits the QSK50 CM2350 K108 engine, which is part of the QSK50 series. This engine is designed for heavy-duty applications and requires precise DEF management to deliver its high power output. The doser injector ensures that the DEF is injected accurately, contributing to the engine’s overall efficiency and longevity.

QST30 CM2350 T101

Lastly, the Doser Injector 4353197 is compatible with the QST30 CM2350 T101 engine. This engine is known for its versatility and is used in a variety of applications. The doser injector ensures that the DEF is delivered in the correct amounts, which is crucial for maintaining the engine’s performance and reliability.

By ensuring that the Doser Injector 4353197 is correctly installed in these engines, operators can expect improved fuel efficiency, reduced emissions, and enhanced engine performance. This compatibility highlights the versatility and reliability of the doser injector in various Cummins engine models.

Role of Part 4353197 Doser Injector in Engine Systems

The Part 4353197 Doser Injector is an integral component in the orchestration of modern engine systems, particularly within the realm of emissions control. Its primary function is to precisely deliver a measured amount of Diesel Exhaust Fluid (DEF) into the exhaust stream. This injection is a key step in the Selective Catalytic Reduction (SCR) process, which is designed to reduce nitrogen oxides (NOx) emissions—a significant contributor to air pollution.

Integration with Aftertreatment Devices

When the Doser Injector is activated, it sprays DEF into the exhaust stream just before it reaches the aftertreatment device. The aftertreatment device, typically a combination of a Diesel Oxidation Catalyst (DOC), a Diesel Particulate Filter (DPF), and an SCR catalyst, relies on the consistent and accurate dosing of DEF to optimize its performance. The DEF reacts with the NOx in the presence of the SCR catalyst, converting these harmful emissions into harmless nitrogen and water vapor.

Synergy with Aftertreatment Injector Kits

The Doser Injector is often part of a comprehensive aftertreatment injector kit, which includes various sensors, control modules, and the injector itself. This kit ensures that the dosing process is finely tuned to the specific requirements of the engine’s exhaust system. The injector kit’s control module monitors exhaust conditions and adjusts the dosing rate in real-time, ensuring that the SCR process is as efficient as possible under varying load and speed conditions.

Contribution to Decomposition Reactors

In systems that incorporate a decomposition reactor, the Doser Injector’s role becomes even more specialized. The decomposition reactor is designed to break down any unreacted DEF or ammonia that may be present in the exhaust stream. The Doser Injector must deliver DEF with precision to avoid over-dosing, which could lead to ammonia slip—a condition where excess ammonia passes through the exhaust system未反应. The injector’s accurate dosing helps maintain the delicate balance required for the decomposition reactor to function effectively, ensuring that the exhaust emissions meet regulatory standards without wasting DEF.

Conclusion

The Cummins 4353197 Doser Injector plays a critical role in modern diesel engine systems by facilitating the reduction of NOx emissions through the precise injection of DEF. Its integration with aftertreatment devices and injector kits ensures optimal performance of the SCR system, contributing to lower emissions and better air quality. Regular maintenance and proper installation are essential for maximizing the benefits of this part, highlighting its importance in achieving environmental compliance and enhancing engine efficiency.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Rectangular Ring Seal | 1 | 5312372 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.