This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4353377 Doser Injector is a component designed for use in commercial trucks. It is integral to the operation of these vehicles, particularly in managing emissions and ensuring engine efficiency. Understanding its function and significance can provide valuable insights into the complexities of modern diesel engine systems.

Basic Concepts of Doser Injectors

A doser injector is a device used in diesel engines to inject a reducing agent, typically diesel exhaust fluid (DEF), into the exhaust stream. This process is part of the selective catalytic reduction (SCR) system, which helps convert nitrogen oxides (NOx) into nitrogen and water, thereby reducing harmful emissions. The doser injector plays a role in this system by precisely metering and injecting DEF into the exhaust stream, where it reacts with the NOx in the presence of a catalyst 1.

Operation of the Cummins 4353377 Doser Injector

The Cummins 4353377 operates by using an electronic control unit (ECU) to determine the precise amount of DEF needed based on engine load, speed, and exhaust temperature. The injector then delivers this fluid into the exhaust stream upstream of the SCR catalyst. This injection process is essential for the chemical reaction that reduces NOx emissions. The injector interacts with various engine components, including the ECU and exhaust system, to ensure optimal performance and emissions control 2.

Purpose of the Cummins 4353377 Doser Injector

The Cummins 4353377 serves a specific role in the operation of a truck by facilitating the reduction of NOx emissions. This reduction is achieved through the SCR process, which the doser injector supports by delivering DEF. Additionally, the injector contributes to engine performance by helping maintain efficient combustion and reducing the environmental impact of diesel engines.

Key Features

The Cummins 4353377 incorporates several design elements and technological advancements to enhance its functionality. These include a robust construction using high-quality materials to withstand the harsh conditions of the exhaust system. The injector also features precise metering technology to ensure accurate DEF delivery, and it is designed for easy integration into existing engine systems.

Benefits of Using the Cummins 4353377 Doser Injector

Using the Cummins 4353377 offers several benefits. It contributes to improved fuel efficiency by supporting optimal engine performance. Additionally, it plays a role in reducing emissions, helping trucks meet stringent environmental regulations. The injector also enhances engine longevity by maintaining efficient combustion and reducing the buildup of harmful deposits in the exhaust system.

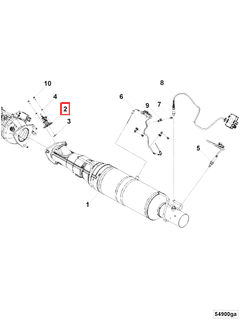

Installation Process

Installing the Cummins 4353377 involves several steps to ensure proper integration into the engine system. The process begins with disconnecting the exhaust system at the appropriate location. The injector is then mounted in place, connected to the DEF supply line, and secured with the necessary fittings. Electrical connections are made to link the injector with the ECU. Finally, the exhaust system is reassembled, and the installation is tested to ensure proper operation.

Common Issues and Troubleshooting

Several issues may arise with the Cummins 4353377, including clogging, leaks, and electrical faults. Troubleshooting these problems involves checking for blockages in the injector or supply lines, inspecting connections for leaks, and verifying electrical connections. Regular maintenance and prompt attention to any issues can help prevent more significant problems and ensure the injector operates effectively.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4353377, regular maintenance is necessary. This includes checking for leaks in the DEF supply system, inspecting electrical connections, and ensuring the injector is free from blockages. Additionally, following the manufacturer’s recommendations for DEF quality and storage can help prevent issues related to fluid contamination.

Cummins Corporation

Cummins Corporation is a leading manufacturer of diesel and natural gas engines, as well as related technologies. Founded in 1919, the company has a long history of innovation in the automotive industry, particularly in engine components. Cummins is known for its commitment to quality, performance, and environmental responsibility, making it a trusted name in the development of advanced engine systems.

Compatibility with Cummins Engines

The Doser Injector 4353377, manufactured by Cummins, is designed to integrate seamlessly with a variety of engine models. This part is essential for ensuring precise fuel delivery, which is critical for optimal engine performance and efficiency.

ISV (Nissan) Engines

For the ISV engines, which are part of the Nissan lineup, the Doser Injector 4353377 is engineered to fit perfectly within the engine’s architecture. This compatibility ensures that the injector can effectively manage the fuel injection process, contributing to the engine’s overall reliability and performance. The integration of this part is critical for maintaining the balance between power output and fuel economy, which is a hallmark of Nissan’s engineering standards.

The Doser Injector 4353377 is specifically tailored to work with the ISV engines, ensuring that it meets the stringent requirements set by Nissan. This part’s design takes into account the unique characteristics of the ISV engines, such as their combustion chamber design and fuel injection system, to provide a seamless fit and function.

Role of Part 4353377 Doser Injector in Aftertreatment Systems

The Part 4353377 Doser Injector is an integral component within the aftertreatment system of modern engines, specifically designed to enhance the efficiency of emissions control. This injector is responsible for the precise delivery of Diesel Exhaust Fluid (DEF) into the exhaust stream.

When the Doser Injector is activated, it sprays DEF into the exhaust gas upstream of the Selective Catalytic Reduction (SCR) catalyst. The DEF, composed of urea and de-ionized water, decomposes into ammonia and carbon dioxide when it comes into contact with the hot exhaust gases. The ammonia then reacts with nitrogen oxides (NOx) in the presence of the SCR catalyst, converting them into harmless nitrogen and water vapor.

The integration of the Doser Injector with the aftertreatment device ensures that the SCR system operates within optimal parameters. The injector’s performance is monitored by the Engine Control Unit (ECU), which adjusts the dosing rate based on real-time data from various sensors, including NOx sensors located both upstream and downstream of the SCR catalyst.

Furthermore, the Doser Injector works in conjunction with other components of the aftertreatment system, such as the Diesel Particulate Filter (DPF) and the Exhaust Gas Recirculation (EGR) system. The DPF captures particulate matter from the exhaust, while the EGR system reduces NOx formation by recirculating a portion of the exhaust gas back into the engine’s intake. The Doser Injector complements these systems by addressing the NOx that remains after the initial reduction processes.

Conclusion

In summary, the Part 4353377 Doser Injector plays a significant role in the aftertreatment process by ensuring the effective reduction of NOx emissions, thereby contributing to overall engine compliance with stringent emissions regulations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.