Introduction

The Cummins 4900354 Injector is a critical component in the fuel system of commercial trucks, designed to deliver fuel efficiently into the engine’s combustion chambers. This part is engineered to meet the rigorous demands of heavy-duty applications, ensuring reliable performance and efficiency across various operating conditions.

Basic Concepts of Fuel Injectors

Fuel injectors, including the Cummins 4900354, are essential for delivering fuel into the combustion chamber of internal combustion engines. They atomize fuel into a fine mist, which mixes with air to create a combustible mixture. The precise control of fuel delivery is vital for efficient combustion, impacting engine performance, fuel efficiency, and emissions. Modern injectors utilize electronic controls to manage the timing and quantity of fuel injected, enhancing engine operation 1.

Purpose of the Cummins 4900354 Injector

The Cummins 4900354 Injector ensures precise fuel delivery to the engine’s combustion chambers, contributing to combustion efficiency by atomizing fuel into a fine mist. This facilitates a more complete burn, resulting in improved engine performance, increased fuel efficiency, and reduced emissions. Its function is integral to maintaining the engine’s power output and overall efficiency 2.

Key Features

This Cummins part is characterized by advanced materials and manufacturing techniques that ensure durability and reliability under demanding conditions. It incorporates precise fuel delivery mechanisms and electronic controls that optimize fuel atomization and combustion efficiency.

Benefits of Using the Cummins 4900354 Injector

Utilizing this injector offers several advantages, including improved fuel efficiency through optimal fuel delivery, enhanced engine performance with increased power output, and smoother operation. Additionally, its design supports lower emission levels, aligning with environmental regulations and promoting sustainable operation 3.

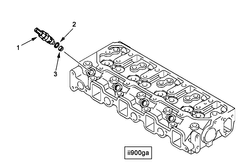

Installation and Integration

Installing the Cummins 4900354 Injector requires adherence to specific procedures to ensure proper integration and operation. This involves connecting the injector to the fuel supply system and securing it within the engine’s combustion chamber. Compatibility with the engine’s electronic control unit (ECU) is necessary for optimal fuel delivery management.

Maintenance and Troubleshooting

Regular inspection and cleaning of the injector are crucial for maintaining its performance and longevity. Common issues, such as clogged nozzles or electronic malfunctions, can be addressed through cleaning or replacement of affected components. Troubleshooting tips include checking for consistent fuel delivery and monitoring engine performance for signs of injector-related problems.

Performance Impact

The Cummins 4900354 Injector significantly impacts the overall performance of a truck by ensuring precise fuel delivery, contributing to increased power output and improved fuel efficiency. Its role in optimizing combustion also leads to lower emission levels, enhancing the truck’s environmental performance under a wide range of operating conditions.

Technological Innovations

This injector incorporates several technological innovations, including advanced fuel delivery mechanisms for precise atomization and combustion, electronic controls for optimized fuel management, and durable construction materials that withstand heavy-duty truck operation. These innovations contribute to the injector’s reliability, efficiency, and performance.

Cummins Company Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, demonstrating a commitment to innovation, quality, and customer satisfaction.

Compatibility with Cummins Engines

The Cummins part number 4900354 is designed to be compatible with a range of Cummins engines, including the A1400, A1700, A2000, and A2300 engine families. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The injector ensures optimal fuel delivery, enhancing combustion efficiency and power output across these engine models 4.

Role of the 4900354 Injector in Engine Systems

The injector, specifically part 4900354, is integral to the efficient operation of modern engine systems. It is responsible for the precise delivery of fuel into the combustion chamber, ensuring an optimal fuel-air mixture for combustion. This component works in concert with the engine control unit (ECU), which monitors various parameters such as engine load, temperature, and throttle position to adjust the fuel injection timing and quantity.

In conjunction with the high-pressure fuel pump, the injector ensures that fuel is delivered at the correct pressure, enhancing combustion efficiency and reducing emissions. The injector also interacts with the intake manifold, where the air-fuel mixture is prepared before entering the combustion chamber.

Additionally, the injector’s performance is influenced by the glow plug system in diesel engines, which aids in cold start conditions by preheating the combustion chamber. In gasoline engines, the injector works with the spark plug to ignite the air-fuel mixture at the precise moment for maximum efficiency.

The injector’s role extends to the overall fuel system, including the fuel rail and return lines, which maintain consistent fuel pressure and facilitate the return of excess fuel to the tank. This ensures that the injector operates within specified parameters, contributing to the engine’s performance and longevity.

Furthermore, the injector is part of a feedback loop that includes oxygen sensors and knock sensors. These sensors provide real-time data to the ECU, allowing for adjustments to the fuel injection process to maintain optimal engine performance and emissions compliance.

Conclusion

The Cummins 4900354 Injector plays a vital role in the efficient operation of commercial trucks by ensuring precise fuel delivery and optimizing combustion efficiency. Its advanced features, compatibility with various Cummins engines, and technological innovations contribute to improved engine performance, fuel efficiency, and reduced emissions. Regular maintenance and proper installation are essential for maximizing the benefits of this component.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavy-duty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2670 B163B Engines. Bulletin Number 6425233.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.