This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, identified by part number 4924626, is a vital component in the fuel system of heavy-duty trucks. Manufactured by Cummins Inc., a prominent figure in the automotive industry, this part ensures efficient fuel delivery to the injectors, contributing to the engine’s performance and reliability.

Function and Operation

The Injector Fuel Supply Tube facilitates the transfer of fuel from the fuel tank to the injectors within the fuel system. It acts as a conduit, ensuring a steady and pressurized flow of fuel, which is essential for the injectors to atomize the fuel properly and deliver it into the combustion chamber. This process is fundamental for maintaining engine efficiency and power output 1.

Key Features

The Injector Fuel Supply Tube is designed for durability and performance. Crafted from high-quality materials, it is resistant to the corrosive effects of fuel and the high pressures within the fuel system. Its robust construction ensures longevity, even under demanding operating conditions. Additionally, the tube is engineered to minimize fuel leakage and maintain consistent fuel pressure, enhancing the overall efficiency of the fuel delivery system 2.

Benefits

Incorporating the Cummins Injector Fuel Supply Tube into the fuel system offers several advantages. It contributes to improved fuel efficiency by ensuring a clean and pressurized fuel supply to the injectors. This results in more efficient combustion and reduced fuel consumption. Furthermore, the tube’s reliable performance under various operating conditions enhances engine performance and ensures consistent power delivery. Its durability and resistance to wear also contribute to the overall reliability of the fuel system 3.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is vital for its effective operation. It is designed to be compatible with a range of Cummins engine models, ensuring a seamless integration into the fuel system. During installation, it is important to follow manufacturer guidelines to ensure a secure fit and proper alignment within the fuel system. Specific requirements may include ensuring the tube is free from obstructions and that all connections are tight to prevent fuel leaks.

Maintenance and Troubleshooting

To ensure the optimal performance of the Injector Fuel Supply Tube, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the tube and its connections can prevent blockages and ensure a smooth fuel flow. Addressing common issues such as leaks or blockages promptly can prevent more significant problems and maintain the efficiency of the fuel system.

Common Issues and Solutions

Common problems with the Injector Fuel Supply Tube may include fuel leaks, blockages, or reduced fuel pressure. These issues can often be traced to wear and tear, corrosion, or improper installation. Solutions may involve cleaning the tube and connections, replacing damaged sections, or ensuring all connections are secure. Regular maintenance and inspections can help identify and address these issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry for producing reliable and high-performance components. Their commitment to excellence is evident in the design and manufacturing of parts like the Injector Fuel Supply Tube, ensuring they meet the demanding requirements of commercial vehicle applications.

Compatibility with Cummins Engines

QSK38 Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, both the CM2150 and CM850 variants, utilize the Injector Fuel Supply Tube to maintain precise fuel pressure and flow. This is crucial for the high-performance demands of these engines, ensuring that the injectors receive the correct amount of fuel at the right time.

QSK50 Engines

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The QSK50 series engines, including the CM2150 and CM2350 variants, also depend on the Injector Fuel Supply Tube for efficient fuel delivery. The K107 and MCRS versions of these engines benefit from this part’s ability to withstand high pressures and deliver consistent fuel flow, which is vital for maintaining engine efficiency and power output.

QSK60 Engines

- QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine incorporates the Injector Fuel Supply Tube to ensure that the injectors receive a steady and accurate fuel supply. This is particularly important for the high-performance demands of this engine model, ensuring that it operates at peak efficiency.

Each of these engines relies on the Injector Fuel Supply Tube to maintain the integrity of the fuel delivery system, ensuring that the injectors function correctly and the engine operates smoothly.

Role of Part 4924626 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 4924626, is an integral component in the fuel delivery system of an engine. It is responsible for channeling pressurized fuel from the fuel supply plumbing to the injectors, ensuring a consistent and reliable fuel flow to the combustion chambers.

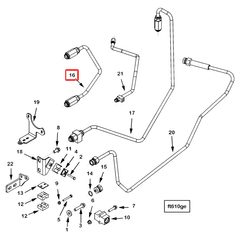

Integration with Fuel Plumbing

The Injector Fuel Supply Tube interfaces directly with the fuel plumbing system. It connects to the fuel supply plumbing, which typically includes a series of pipes, hoses, and fittings that transport fuel from the fuel tank to various points within the engine bay. This connection is vital for maintaining the integrity of the fuel supply line and preventing leaks or fuel starvation.

Interaction with Cylinder Head and Injectors

Once the fuel passes through the Injector Fuel Supply Tube, it is delivered to the injectors, which are usually mounted on the cylinder head. The cylinder head is a critical component that houses the combustion chambers, valves, and spark plugs. The Injector Fuel Supply Tube ensures that each injector receives the precise amount of fuel needed for optimal combustion, directly influencing engine performance and efficiency.

Relationship with Camshaft and Camshaft Cover

Although the Injector Fuel Supply Tube does not directly interact with the camshaft or camshaft cover, the proper functioning of the fuel system is essential for the overall performance of the engine. The camshaft, along with its associated gear and cover, plays a significant role in the valve timing and operation. Efficient fuel delivery, facilitated by the Injector Fuel Supply Tube, ensures that the air-fuel mixture is combusted at the correct moment, enhancing engine responsiveness and power output.

Contribution to Connecting Rod and Piston Assembly

The performance of the connecting rod and piston assembly is also indirectly influenced by the Injector Fuel Supply Tube. Consistent and precise fuel delivery leads to more controlled and efficient combustion events. This, in turn, reduces the stress on the connecting rod and piston, promoting longevity and reliability of these components.

Importance in Performance Parts

In engines equipped with performance parts, the Injector Fuel Supply Tube becomes even more significant. High-performance engines often demand increased fuel flow to meet the demands of enhanced power output. The Injector Fuel Supply Tube must be capable of handling higher pressures and flow rates without compromising the fuel delivery system’s integrity. This ensures that performance parts, such as upgraded injectors or fuel pumps, function optimally.

Conclusion

The Injector Fuel Supply Tube (part 4924626) plays a pivotal role in the fuel delivery system, ensuring that fuel is efficiently and reliably supplied to the injectors. Its integration with various engine components underscores its importance in maintaining overall engine performance and reliability.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.