This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Injector Fuel Supply Tube, identified by part number 4934470, is a component manufactured by Cummins, a leading name in diesel engine technology. This part plays a role in the fuel system of heavy-duty trucks. Fuel supply tubes are integral to diesel engines, facilitating the delivery of fuel from the fuel tank to the injectors. Understanding the function and importance of the Injector Fuel Supply Tube is key to maintaining the efficiency and reliability of a truck’s engine.

Basic Concepts and Functionality

The Injector Fuel Supply Tube operates on fundamental principles that ensure the proper functioning of the fuel injection system. Its primary role is to transport fuel under pressure from the fuel pump to the injectors. This process is vital for the precise delivery of fuel to the combustion chamber, where it mixes with air and ignites to produce power. The tube must withstand high pressures and temperatures, ensuring a consistent fuel supply that meets the engine’s demands 1.

Purpose and Role in Truck Operation

In the context of a truck’s fuel system, the Injector Fuel Supply Tube serves a function. It ensures that fuel is delivered efficiently and reliably to the injectors, which in turn spray atomized fuel into the combustion chamber. This precise fuel delivery is fundamental to the engine’s performance, affecting factors such as power output, fuel efficiency, and emissions. The tube’s role in maintaining a consistent fuel supply contributes to the overall efficiency and reliability of the engine 2.

Key Features

The Cummins Injector Fuel Supply Tube is designed with several key features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the harsh conditions within a diesel engine. The design may include reinforced sections to handle high pressures and temperatures, as well as smooth internal surfaces to ensure unimpeded fuel flow. These features contribute to the tube’s longevity and reliability in demanding applications 3.

Benefits

Using the Cummins Injector Fuel Supply Tube offers several benefits. It contributes to improved fuel efficiency by ensuring a consistent and precise fuel delivery to the injectors. This can lead to enhanced engine performance, as the engine operates more efficiently with a reliable fuel supply. Additionally, the durability and reliability of the tube can reduce maintenance costs and downtime, making it a valuable component for heavy-duty truck operations.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the longevity and optimal performance of the Injector Fuel Supply Tube. Common issues may include leaks, blockages, or damage from high pressures and temperatures. Regular inspections can help identify these issues early, allowing for timely repairs or replacements. Maintenance practices should include checking for signs of wear or damage, ensuring proper connections, and following manufacturer guidelines for replacement intervals.

Installation and Replacement

Proper installation and replacement of the Injector Fuel Supply Tube are important for avoiding potential issues and ensuring safe and efficient operation. Step-by-step instructions should be followed to ensure that the tube is correctly positioned and secured. This includes verifying that all connections are tight and that the tube is free from kinks or obstructions. Proper installation techniques help maintain the integrity of the fuel system and prevent leaks or other issues.

Common Failure Modes

Common failure modes associated with the Injector Fuel Supply Tube include leaks, blockages, and material fatigue. These failures can be caused by a variety of factors, such as wear and tear, exposure to high pressures and temperatures, or improper installation. Understanding these failure modes can help in identifying the root causes and implementing preventive measures, such as regular maintenance and using high-quality replacement parts.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of reliable and innovative engine solutions. The company is committed to advancing technology, improving efficiency, and delivering exceptional customer satisfaction in the automotive industry. Cummins’ expertise and dedication to quality make it a preferred choice for heavy-duty truck applications.

Cummins Injector Fuel Supply Tube (Part 4934470)

The Cummins Injector Fuel Supply Tube, identified by part number 4934470, is a component in the fuel delivery system of certain Cummins engines. This part ensures that fuel is efficiently and accurately delivered to the fuel injectors, which is essential for maintaining optimal engine performance and fuel efficiency.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube (4934470) is specifically designed to fit the following Cummins engines:

- 4B3.9: This engine model benefits from the precise fuel delivery facilitated by the 4934470 part, ensuring that the fuel injectors receive the correct amount of fuel under varying operating conditions.

The injector fuel supply tube is engineered to withstand the high pressures and temperatures typical in diesel engines, ensuring durability and reliability over extended periods of use. Its design allows for seamless integration with the engine’s fuel system, providing a secure connection that minimizes leaks and maintains system integrity.

Role of Part 4934470 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 4934470, is a component in the fuel delivery system of an engine. This tube is responsible for transporting fuel from the fuel rail to the injectors, ensuring a consistent and reliable fuel supply to the combustion chambers.

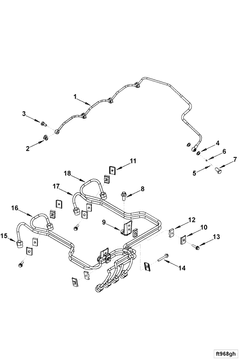

Integration with Fuel System Components

-

Fuel Rail: The Injector Fuel Supply Tube connects directly to the fuel rail, which is a pressurized manifold that distributes fuel to each injector. The tube ensures that fuel is evenly distributed and maintains the required pressure for optimal injector performance.

-

Fuel Injectors: Each injector is supplied with fuel through the Injector Fuel Supply Tube. The tube’s design allows for precise fuel metering, which is vital for achieving the correct air-fuel ratio necessary for efficient combustion.

-

Fuel Pump: While not directly connected, the fuel pump’s role in pressurizing the fuel system is complemented by the Injector Fuel Supply Tube. The tube helps maintain the pressure needed for the injectors to function correctly.

-

Fuel Filter: Positioned upstream in the fuel system, the fuel filter removes contaminants from the fuel before it reaches the Injector Fuel Supply Tube. This ensures that only clean fuel is delivered to the injectors, preventing clogs and ensuring smooth operation.

Interaction with Plumbing Components

-

Fuel Lines: The Injector Fuel Supply Tube is often part of a network of fuel lines that transport fuel throughout the engine system. These lines must be securely connected to the tube to prevent leaks and ensure a consistent fuel flow.

-

Fittings and Connectors: Various fittings and connectors are used to join the Injector Fuel Supply Tube to other components in the fuel system. These must be properly sealed to maintain system integrity and prevent fuel leaks.

-

Seals and Gaskets: To ensure a leak-free connection, seals and gaskets are used at the junctions where the Injector Fuel Supply Tube meets other components. These components are essential for maintaining the pressurized fuel system.

Conclusion

In summary, the Injector Fuel Supply Tube (part 4934470) plays a role in the fuel delivery system by ensuring that fuel is efficiently and reliably supplied to the injectors, contributing to the overall performance and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.