4941156

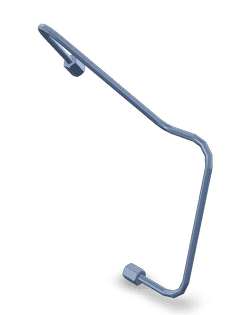

Injector Fuel Supply Tube

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Screw Assembly 4941156 is a specialized component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This screw assembly is designed to meet the rigorous demands of commercial truck applications, ensuring durability and reliability in various operational conditions.

Purpose and Function

The Fracture Resistant Screw Assembly plays a role in securing critical components within the truck’s engine and chassis systems. Its primary function is to provide a secure fastening solution that can withstand high stress and dynamic loads, which are common in heavy-duty truck operations. By maintaining the integrity of these connections, the screw assembly contributes to the overall functionality and safety of the vehicle, ensuring that components remain securely in place under varying conditions 1.

Key Features

The Fracture Resistant Screw Assembly is characterized by its robust design and the use of high-strength materials. It is engineered to resist fractures under extreme stress, which is a common concern in heavy-duty applications. The assembly features a precision-machined thread and a head design that facilitates easy installation and removal. Additionally, it may include coatings or treatments that enhance corrosion resistance, further contributing to its durability in harsh environments.

Benefits

Utilizing the Fracture Resistant Screw Assembly offers several advantages. It provides improved reliability by ensuring that critical fasteners remain intact under stress, reducing the likelihood of component failure. This results in reduced maintenance needs, as the assembly is designed to withstand the rigors of heavy-duty use with minimal wear. Enhanced safety features are also a benefit, as the secure fastening provided by the assembly helps prevent accidents related to component detachment.

Installation and Usage

Proper installation of the Fracture Resistant Screw Assembly is crucial for optimal performance. It is recommended to use the correct torque specifications provided by the manufacturer to ensure that the screw is tightened to the appropriate level without over-tightening, which could lead to damage. Specific tools, such as torque wrenches, may be required to achieve the precise installation. Following the manufacturer’s guidelines for installation will help ensure the assembly functions as intended.

Troubleshooting and Maintenance

Common issues with the Fracture Resistant Screw Assembly may include loosening over time due to vibration or corrosion. Regular inspections are recommended to check for signs of wear or damage. If loosening is detected, re-tightening to the specified torque is advised. In cases where corrosion is present, cleaning the affected area and applying a corrosion-resistant coating may help prolong the assembly’s lifespan. Should the screw show signs of significant wear or damage, replacement is recommended to maintain the integrity of the fastening.

Manufacturer - Cummins

Cummins is a reputable manufacturer with a long-standing history in the automotive industry, particularly in the production of diesel engines and related components. The company is known for its commitment to quality and innovation, producing components that are designed to meet the demanding requirements of commercial and heavy-duty applications. Cummins’ reputation for reliability and performance makes it a trusted name among professionals in the industry.

Application in Cummins Engines

The Fracture Resistant Screw Assembly, identified by part number 4941156, is a critical component in several Cummins engine models. This part is designed to enhance the durability and reliability of the engine by providing a robust fastening solution that can withstand high stress and operational demands.

Application in Cummins Engines

-

QSB3.3 CM2150: This engine is part of the Cummins QSB series, known for its reliability and performance in various industrial applications. The Fracture Resistant Screw Assembly is integral to the engine’s structural integrity, ensuring that critical components remain securely fastened under extreme conditions.

-

QSB6.7 CM2250: Another engine in the Cummins QSB series, the QSB6.7 CM2250 benefits from the enhanced durability provided by the Fracture Resistant Screw Assembly. This part is crucial in maintaining the alignment and stability of engine components, contributing to the engine’s overall longevity and efficiency.

-

QSC3.8 CM2300: The QSC3.8 CM2300 is a compact and powerful engine designed for heavy-duty applications. The Fracture Resistant Screw Assembly plays a vital role in securing various engine parts, ensuring that the engine can operate reliably under heavy loads and in demanding environments.

Grouping of Engines

The Fracture Resistant Screw Assembly is particularly important in the Cummins QSB and QSC series engines. These engines are widely used in agricultural, construction, and industrial applications, where reliability and durability are paramount. The use of this part in these engines underscores Cummins’ commitment to providing high-quality, long-lasting components that enhance engine performance and reduce maintenance needs.

Role of Part 4941156 Fracture Resistant Screw Assembly in Engine Systems

The part 4941156 Fracture Resistant Screw Assembly is instrumental in maintaining the integrity and performance of several key components within engine systems.

Connecting Rod Integration

In the context of the connecting rod, the 4941156 screw assembly is utilized to secure the rod to the crankshaft. This connection is vital for the transmission of force from the piston to the crankshaft, enabling the rotational motion necessary for engine operation. The fracture-resistant properties of the screw assembly ensure that this connection remains secure under the high stresses and dynamic loads experienced during engine operation.

Piston Assembly Application

When it comes to the piston, the 4941156 screw assembly may be employed in securing components such as the piston pin or wrist pin. This pin connects the piston to the connecting rod, allowing for the smooth transfer of motion. The robust nature of the fracture-resistant screw assembly helps in withstanding the cyclic loading and thermal stresses that the piston experiences, thereby contributing to the longevity and reliability of the piston assembly.

Overall Engine System Contribution

In broader engine system applications, the 4941156 screw assembly plays a significant role in ensuring that various components remain firmly attached and operational under the demanding conditions of engine operation. Its fracture-resistant design is particularly beneficial in high-performance or high-stress engine environments, where component durability and reliability are paramount 2.

Conclusion

The Fracture Resistant Screw Assembly 4941156 by Cummins is a critical component in ensuring the durability and reliability of heavy-duty truck and engine applications. Its robust design, high-strength materials, and fracture-resistant properties make it an essential part in securing critical engine components under extreme conditions. Proper installation, regular maintenance, and timely replacement are key to maximizing the benefits of this Cummins part, contributing to the overall performance and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.