This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

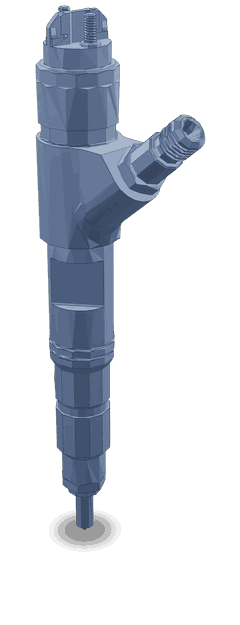

The Cummins 4947582 Injector is a component designed for use in heavy-duty trucks. It serves a vital role in the fuel delivery system, ensuring efficient combustion and optimal engine performance. Understanding its function and significance is key to maintaining and enhancing the operation of heavy-duty vehicles.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air for combustion. The precise control of fuel delivery by injectors is crucial for efficient engine operation, impacting both performance and emissions 1.

Purpose of the Cummins 4947582 Injector

The Cummins 4947582 Injector is integral to the fuel delivery system in heavy-duty trucks. It ensures that fuel is delivered at the correct pressure and timing, contributing to efficient combustion. This injector plays a role in enhancing fuel atomization, which leads to more complete combustion and improved engine efficiency 2.

Key Features

The Cummins 4947582 Injector is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features that enhance its performance, such as precise fuel metering and durable construction. These features contribute to its reliability and efficiency in demanding applications 3.

Benefits of Using the Cummins 4947582 Injector

Utilizing the Cummins 4947582 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring optimal fuel delivery. Additionally, it enhances engine performance through more efficient combustion. The injector’s design also supports reliability, reducing the likelihood of fuel system issues.

Installation and Compatibility

Proper installation of the Cummins 4947582 Injector is crucial for its effective operation. It is designed to be compatible with specific Cummins engine models, ensuring seamless integration into the fuel system. Following manufacturer guidelines during installation helps maintain the injector’s performance and longevity.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4947582 Injector is important for ensuring its optimal performance. This includes periodic inspections, cleaning to remove any deposits, and checking for wear or damage. Troubleshooting common issues such as misfires or fuel delivery problems often involves inspecting the injector for blockages or malfunctions.

Performance Enhancements

The Cummins 4947582 Injector contributes to overall engine performance by improving fuel atomization and combustion efficiency. This can lead to enhancements in power output, torque, and fuel economy. Its role in the fuel delivery system is fundamental to achieving these performance benefits.

Environmental Impact

The use of the Cummins 4947582 Injector can have positive environmental impacts. By promoting more complete combustion, it helps reduce emissions. Additionally, its contribution to improved fuel efficiency means less fuel is consumed per mile, further reducing the environmental footprint of heavy-duty trucks.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation in diesel engines and power generation, Cummins is committed to advancing technology for a more sustainable future. The company’s product offerings include engines, filtration, emissions solutions, and power systems, all designed to meet the demanding needs of various industries.

Cummins Injector 4947582 Compatibility

The Cummins injector part number 4947582 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This injector is engineered to meet the stringent demands of various engine applications, providing precise fuel delivery and enhancing overall engine efficiency.

ISF3.8 CM2220 AN Engines

The injector 4947582 is specifically compatible with the ISF3.8 CM2220 AN engines. These engines are known for their robust construction and high performance, making them suitable for a range of heavy-duty applications. The injector’s design ensures it integrates smoothly with the engine’s fuel system, delivering consistent fuel atomization and combustion efficiency.

Integration and Performance

When installed in the ISF3.8 CM2220 AN engines, the injector 4947582 works in harmony with the engine’s electronic control unit (ECU) to regulate fuel injection timing and quantity. This synchronization is crucial for maintaining engine performance, reducing emissions, and extending the engine’s lifespan.

The injector’s precision engineering allows it to withstand the high pressures and temperatures typical of diesel engines, ensuring durability and reliability under demanding conditions. Its compatibility with the ISF3.8 CM2220 AN engines underscores Cummins’ commitment to providing high-quality components that enhance engine performance and longevity.

Role of Part 4947582 Injector in Engine Systems

The 4947582 injector is an essential component within the engine system, working in concert with various other parts to ensure optimal engine performance. Its primary function is to deliver a precise amount of fuel into the combustion chamber at the exact moment it is needed. This timing and precision are vital for efficient combustion, which directly influences the engine’s power output and fuel efficiency.

Interaction with Connecting Rod and Piston

The injector’s role becomes particularly significant when considering its interaction with the connecting rod and piston. As the piston moves downward during the intake stroke, the injector releases fuel into the combustion chamber. This fuel mixes with the air that has been drawn into the chamber. The precise timing of the fuel injection is designed to coincide with the piston’s position, ensuring that the air-fuel mixture is optimal for combustion when the piston reaches the top of its compression stroke.

The connecting rod, which links the piston to the crankshaft, plays a part in this process by transferring the force generated from the combustion of the air-fuel mixture into mechanical energy. This energy is then used to rotate the crankshaft, which in turn drives the engine’s output shaft. The efficiency of this energy transfer is highly dependent on the quality of the combustion process, which is influenced by the injector’s performance.

Contribution to Performance Parts

In engines equipped with performance parts, the 4947582 injector’s role is even more pronounced. Performance parts, such as high-flow air intakes, upgraded exhaust systems, and modified camshafts, are designed to increase the engine’s power output and efficiency. The injector must be capable of delivering the increased fuel demand that these modifications require, without compromising the precision of the fuel delivery.

For instance, a high-flow air intake system allows more air to enter the combustion chamber, which necessitates a corresponding increase in fuel to maintain the optimal air-fuel ratio. The injector must be able to respond to these changes in real-time, ensuring that the engine operates efficiently under all conditions. Similarly, a modified camshaft that alters the timing of the valve openings will affect the air-fuel mixture’s compression and combustion timing. The injector must adapt to these changes to ensure that the fuel is delivered at the precise moment it is needed for optimal combustion.

Conclusion

In summary, the Cummins 4947582 injector plays a significant role in the engine system by ensuring precise fuel delivery, which is essential for efficient combustion and optimal engine performance. Its interaction with the connecting rod and piston, as well as its contribution to the functionality of performance parts, underscores its importance in modern engine systems.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.