This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4972999 Doser Injector is a component designed for use in heavy-duty trucks, specifically within the Selective Catalytic Reduction (SCR) system. Its purpose is to inject Diesel Exhaust Fluid (DEF) into the exhaust stream, which plays a role in reducing nitrogen oxide (NOx) emissions. This Cummins part is significant in the operation of heavy-duty trucks as it helps meet stringent emissions regulations while maintaining engine performance 1.

Basic Concepts of Doser Injectors

A doser injector is a device used in diesel engines to introduce DEF into the exhaust stream. This process is part of the SCR system, which is designed to convert NOx into harmless nitrogen and water vapor. The doser injector works by spraying DEF into the exhaust, where it mixes with the hot exhaust gases. This mixture then passes through a catalyst, where the chemical reaction takes place to reduce NOx emissions 2.

Purpose of the Cummins 4972999 Doser Injector

The Cummins 4972999 Doser Injector serves a specific function within the SCR system of a truck. It is responsible for injecting DEF at precise intervals and quantities to ensure optimal reduction of NOx emissions. This injector contributes to the overall efficiency of the SCR system by providing the necessary DEF dosage for the catalytic conversion process 3.

Key Features

The Cummins 4972999 Doser Injector is characterized by its robust design and construction from high-quality materials, ensuring durability and reliability in demanding operating conditions. It incorporates advanced technological features such as precise control over DEF injection timing and quantity, which are crucial for effective emissions reduction. The injector’s design also facilitates easy integration into the truck’s exhaust system.

Benefits of Using the Cummins 4972999 Doser Injector

Utilizing the Cummins 4972999 Doser Injector offers several advantages. It contributes to improved emissions performance by effectively reducing NOx levels, helping trucks comply with environmental regulations. Additionally, the injector supports enhanced engine efficiency by ensuring the SCR system operates at peak performance. This can lead to benefits such as reduced fuel consumption and lower maintenance costs over time.

Installation and Integration

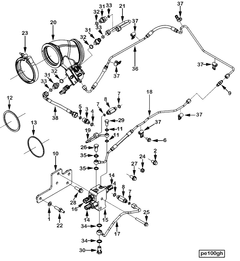

Proper installation of the Cummins 4972999 Doser Injector involves careful consideration of its placement within the exhaust system to ensure optimal DEF delivery. It is important to follow manufacturer guidelines for installation to avoid issues such as DEF contamination or inefficient emissions reduction. Integration into the truck’s engine system requires attention to detail to ensure compatibility and proper function within the SCR system.

Maintenance and Troubleshooting

Maintaining the Cummins 4972999 Doser Injector is crucial for its longevity and performance. Regular inspection and cleaning of the injector can prevent buildup and ensure consistent DEF delivery. Troubleshooting common issues, such as irregular DEF injection or system errors, may involve checking for blockages, verifying electrical connections, and ensuring the injector is functioning within specified parameters.

Performance and Efficiency

The Cummins 4972999 Doser Injector has a notable impact on the performance and efficiency of a truck’s engine. By effectively reducing NOx emissions, it allows the engine to operate more cleanly, which can contribute to overall fuel efficiency. The injector’s role in the SCR system ensures that the engine maintains compliance with emissions standards without compromising on power output or performance.

Environmental Impact

The use of the Cummins 4972999 Doser Injector contributes to environmental benefits by significantly reducing NOx emissions from heavy-duty trucks. This reduction in emissions plays a part in improving air quality and mitigating the environmental impact of diesel engines. The injector’s efficient operation within the SCR system is a key component in achieving these environmental goals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to sustainability, Cummins has established a reputation for quality and reliability in the industry. The company’s focus on advancing technology and reducing environmental impact is evident in its product offerings, including the Cummins 4972999 Doser Injector.

Compatibility of Doser Injector Part 4972999 with Cummins Engines

The Doser Injector part 4972999, manufactured by Cummins, is a critical component designed to ensure precise fuel delivery in various engine models. This part is engineered to fit seamlessly with several Cummins engines, enhancing their performance and efficiency.

ISM CM876

The ISM CM876 engine benefits from the precise fuel management provided by the Doser Injector part 4972999. This engine, known for its robust performance, integrates this injector to maintain optimal fuel economy and power output.

ISX CM871

Similarly, the ISX CM871 engine utilizes the Doser Injector part 4972999 to achieve superior fuel efficiency and power. This engine, often used in heavy-duty applications, relies on the injector’s precision to deliver consistent performance.

ISX15 CM2250 and ISX15 CM2350 X101

Both the ISX15 CM2250 and ISX15 CM2350 X101 engines are designed for high-performance applications. The Doser Injector part 4972999 is integral to these engines, ensuring that they deliver the required power and efficiency. The injector’s compatibility with these models allows for seamless integration and reliable operation.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine also incorporates the Doser Injector part 4972999. This engine, known for its versatility, benefits from the injector’s precision in fuel delivery, ensuring optimal performance across various applications.

QSX11.9 CM2250 ECF and QSX15 CM2250 ECF

The QSX11.9 CM2250 ECF and QSX15 CM2250 ECF engines are designed for demanding conditions. The Doser Injector part 4972999 is essential for these engines, providing the necessary precision in fuel delivery to maintain performance and efficiency.

QSX15 CM2350 X105

Finally, the QSX15 CM2350 X105 engine also utilizes the Doser Injector part 4972999. This engine, known for its high power output, relies on the injector to ensure that it delivers the required performance consistently.

Role of Part 4972999 Doser Injector in Engine Systems

The 4972999 Doser Injector is an integral component in the orchestration of various engine systems, particularly within the aftertreatment system. Its primary function is to precisely deliver a measured amount of Diesel Exhaust Fluid (DEF) into the exhaust stream. This process is essential for the Selective Catalytic Reduction (SCR) system to operate effectively, converting harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor.

When integrated with the Aftercooler Injector Service Kit, the Doser Injector ensures that the DEF is introduced at an optimal temperature and location within the exhaust system. The aftercooler plays a significant role in cooling the exhaust gases before they reach the SCR catalyst, enhancing the efficiency of the DEF injection process.

In the broader Aftertreatment System, the Doser Injector works in concert with other components to maintain emissions within regulatory limits. It communicates with the Engine Control Unit (ECU) to adjust the DEF dosage based on real-time data such as exhaust temperature, engine load, and NOx sensor readings.

The Fluid Doser system, of which the 4972999 is a part, is responsible for the storage, heating, and precise metering of DEF. The doser injector’s role is to atomize the DEF into fine droplets, ensuring maximum surface area contact with the exhaust gases for efficient reduction reactions.

Although not directly connected, the Fuel Filter and Fuel Filter Head contribute to the overall engine performance and efficiency. A clean fuel supply ensures that the engine operates smoothly, which in turn affects the exhaust characteristics and the demand for DEF injection. The fuel filter head manages the flow of fuel to the engine, maintaining consistent pressure and flow rates that are monitored by the ECU, indirectly influencing the DEF dosing strategy.

Conclusion

In summary, the 4972999 Doser Injector is a key player in the aftertreatment system, ensuring that DEF is delivered with precision to meet emissions standards while working in harmony with other engine components to maintain optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.