This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

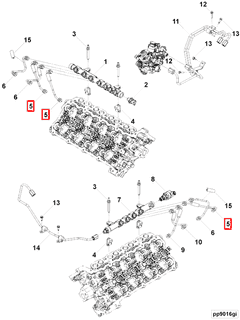

The Cummins Injector Fuel Supply Tube is a vital component in the fuel system of commercial truck engines. This part plays a crucial role in ensuring the efficient delivery of fuel to the injectors, which is essential for optimal engine performance and reliability. Understanding its function and importance can help mechanics and engineers maintain and troubleshoot truck engines more effectively.

Basic Concepts Related to the Injector Fuel Supply Tube

An injector fuel supply tube is a conduit that delivers fuel from the fuel tank to the injectors in the engine. Its primary function is to provide a consistent and pressurized fuel supply, ensuring that the injectors can atomize the fuel properly for combustion. The tube is typically made from durable materials such as stainless steel or high-grade polymers to withstand high pressure and temperature conditions. Design considerations include the tube’s diameter, length, and the quality of its connections to ensure minimal fuel leakage and maximum efficiency 1.

How the Injector Fuel Supply Tube Works

The fuel delivery process begins when the fuel pump pressurizes the fuel in the tank. The pressurized fuel then travels through the supply tube to the injectors. The tube must maintain a consistent pressure and flow rate to ensure that the injectors receive the correct amount of fuel at the right time. Proper sealing is critical to prevent fuel leaks, which can lead to inefficient combustion and potential engine damage. The tube interacts with other components such as the fuel filter, fuel pump, and injectors, making its role integral to the overall fuel injection system 2.

Purpose of the Cummins Injector Fuel Supply Tube (Part #4977899)

The Cummins Injector Fuel Supply Tube (Part #4977899) is designed to ensure efficient fuel delivery to the injectors. This efficiency contributes significantly to engine performance and reliability. By maintaining a consistent fuel supply, the tube helps optimize fuel economy and reduce emissions, making it a critical component in modern heavy-duty truck engines 3.

Role in the Operation of a Truck

In the context of a truck’s operation, the injector fuel supply tube is integrated with the engine’s fuel injection system. For high-performance engines used in heavy-duty applications, the tube’s role is even more pronounced. It ensures that the engine receives the precise amount of fuel needed under various operating conditions, which is essential for maintaining overall vehicle efficiency and longevity.

Troubleshooting and Maintenance

Common issues associated with the injector fuel supply tube include leaks, blockages, and wear. Diagnostic techniques for identifying problems may involve visual inspections, pressure tests, and flow rate measurements. Maintenance best practices to prolong the lifespan of the tube include regular inspections, cleaning, and replacing worn-out components. When replacement is necessary, it is crucial to use OEM parts to ensure compatibility and performance.

Cummins: A Leader in Engine Technology

Cummins has a long-standing reputation for quality and innovation in the commercial truck industry. The company’s commitment to producing reliable and high-performance engine components is evident in their injector fuel supply tubes. Cummins’ role in the industry is characterized by continuous improvement and a focus on meeting the demanding needs of heavy-duty applications.

Expert Insights and Best Practices

Industry experts recommend several best practices for managing and maintaining injector fuel supply tubes. These include regular maintenance schedules, using high-quality replacement parts, and training staff on proper diagnostic techniques. Case studies have shown that fleets that adhere to these practices experience fewer downtimes and longer engine lifespans. Recommendations for fleet operators and mechanics include investing in training and quality parts to ensure optimal performance.

Compatibility of Cummins Injector Fuel Supply Tube 4977899

The Cummins Injector Fuel Supply Tube part number 4977899 is designed to fit seamlessly with various engine models. This part is critical for ensuring the proper delivery of fuel to the injectors, which is essential for maintaining engine performance and efficiency.

ISV (Nissan) Engines

For ISV engines manufactured by Nissan, the Cummins Injector Fuel Supply Tube 4977899 is engineered to integrate smoothly with the engine’s fuel system. This compatibility ensures that the fuel supply remains uninterrupted, which is vital for the engine’s operation. The design of this part allows for a secure fit, reducing the risk of leaks and ensuring that the engine receives the correct amount of fuel.

Grouping by Application

When considering the application of the Cummins Injector Fuel Supply Tube 4977899, it is important to note that this part is often used in heavy-duty and industrial engines. These engines typically require robust and reliable components to handle the demanding conditions they operate under. The injector fuel supply tube is no exception, as it is built to withstand the rigors of continuous use in high-performance environments.

By ensuring that the injector fuel supply tube is correctly installed, engine operators can maintain optimal fuel efficiency and performance. This part’s compatibility with ISV engines by Nissan highlights its versatility and reliability in various industrial applications.

Role of Part 4977899 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 4977899, is an essential component in the fuel delivery system of an engine. It is responsible for directing pressurized fuel from the fuel pump to the injectors, ensuring a consistent and reliable fuel supply for combustion.

Integration with Key Engine Components

Fuel Tube Kit

The Injector Fuel Supply Tube works in conjunction with the Fuel Tube Kit to create a sealed and efficient pathway for fuel. This integration minimizes fuel leaks and ensures that the fuel reaches the injectors under the correct pressure.

Injector

Directly connected to the injector, the Injector Fuel Supply Tube ensures that each cylinder receives the precise amount of fuel needed for optimal performance. This direct connection is vital for maintaining fuel efficiency and engine performance.

Upper Engine Gasket Kit

The Upper Engine Gasket Kit plays a supportive role by ensuring that the fuel supply tube is properly sealed within the engine compartment. This prevents fuel leaks and maintains the integrity of the fuel delivery system.

Camshaft and Front Crankshaft Seal Kit

While the Injector Fuel Supply Tube is primarily involved in the fuel delivery process, its proper installation and maintenance are influenced by the overall engine condition. Components like the Camshaft and Front Crankshaft Seal Kit contribute to the engine’s stability and precision, indirectly affecting the performance of the fuel supply tube.

Service Kit

Regular maintenance using a comprehensive Service Kit ensures that the Injector Fuel Supply Tube remains in optimal condition. This includes checking for wear, corrosion, and proper sealing, which are essential for the longevity and efficiency of the fuel delivery system.

Performance and Reliability

The Injector Fuel Supply Tube’s role in the engine system is to enhance performance and reliability. By ensuring a consistent fuel supply, it contributes to smooth engine operation, reduced emissions, and improved fuel economy.

Conclusion

In summary, the Cummins Injector Fuel Supply Tube (Part #4977899) is a critical component in the fuel system of commercial truck engines. Its role in ensuring efficient fuel delivery contributes to engine performance, reliability, fuel economy, and reduced emissions. Regular maintenance and proper troubleshooting are essential to prolong the lifespan of this component and ensure the overall efficiency and longevity of the vehicle. Understanding and managing the injector fuel supply tube is key to maintaining high-performing truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.