This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

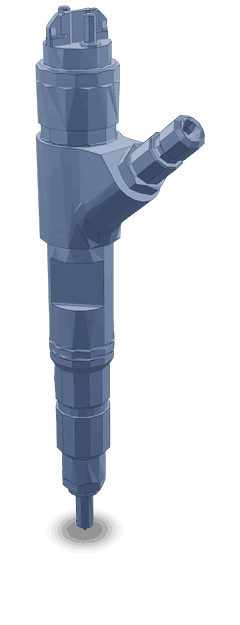

Introduction To The Cummins 5283275 Injector

The Cummins 5283275 injector is a critical component in the operation of commercial truck engines. This article aims to provide an in-depth understanding of the injector’s function, its role in engine performance, and maintenance best practices. By the end of this article, readers will have a solid grasp of this Cummins part and its significance in commercial truck operations.

Basic Concepts Of Fuel Injectors

Fuel injectors are electromechanical valves that precisely control the delivery of fuel into an engine’s combustion chamber. They are integral to modern internal combustion engines, ensuring optimal fuel atomization and combustion efficiency. The Cummins 5283275 injector is designed to meet the stringent demands of heavy-duty truck engines, providing reliable performance under various operating conditions 1.

How The Cummins 5283275 Injector Works

The Cummins 5283275 injector operates by using an electromagnetic coil to control a pintle or needle valve. When the engine control unit (ECU) sends a signal to the injector, the coil creates a magnetic field that lifts the valve, allowing fuel to flow into the combustion chamber. The duration and frequency of the signal determine the amount of fuel injected, ensuring precise control over the fuel-air mixture 2.

Role Of The Cummins 5283275 Injector In Truck Engines

This Cummins part plays a pivotal role in the operation of commercial truck engines. It ensures that the correct amount of fuel is delivered at the right time, which is crucial for maintaining engine efficiency, performance, and emissions compliance. Proper functioning of the injector is essential for maximizing fuel economy, reducing exhaust emissions, and extending engine life 3.

Troubleshooting The Cummins 5283275 Injector

Regular maintenance and timely troubleshooting are key to ensuring the longevity and performance of the Cummins 5283275 injector. Common issues include:

- Clogged Injectors: Deposits from contaminated fuel can cause blockages. Regular fuel filtration and using high-quality fuel can prevent this.

- Leaking Injectors: Leaks can result from worn seals or damaged components. Inspecting and replacing faulty injectors promptly is crucial.

- Electrical Issues: Faulty wiring or connections can disrupt the injector’s operation. Regular electrical inspections and repairs are necessary.

Maintenance Best Practices For The Cummins 5283275 Injector

To maintain the optimal performance of the Cummins 5283275 injector, consider the following best practices:

- Regular Inspections: Conduct routine visual inspections for signs of wear, corrosion, or damage.

- Fuel Quality: Use high-quality, clean fuel to prevent deposits and blockages.

- Scheduled Servicing: Follow the manufacturer’s recommended service intervals for injector cleaning and replacement.

- Proper Storage: When not in use, store injectors in a clean, dry environment to prevent contamination and corrosion.

About Cummins

Cummins is a global power leader and a pioneer in the design and manufacture of engines, engine-related technology, and related parts and services. With a commitment to innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. Their injectors are engineered to deliver exceptional performance, reliability, and durability, meeting the demanding needs of heavy-duty applications 4.

Cummins Injector 5283275 Compatibility

The Cummins injector part number 5283275 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This injector is compatible with the following engines:

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- QSF3.8 CM2880 F112

These engines, while sharing the same base model ISF3.8 CM2220, have slight variations in their configurations, which the injector 5283275 accommodates effectively. The injector’s design allows it to integrate smoothly with the fuel injection system of these engines, providing precise fuel delivery and enhancing overall engine efficiency 5.

Role of Part 5283275 Injector in Engine Systems

The part 5283275 injector is integral to the efficient operation of various engine components. When integrated into the engine system, it works in concert with the connecting rod and piston to enhance engine performance. As the piston moves within the cylinder, the injector precisely delivers fuel into the combustion chamber, ensuring optimal air-fuel mixture for combustion.

The cylinder head, which houses the combustion chamber, relies on the injector to maintain consistent fuel delivery. This consistency is vital for stable engine operation and power output. The injector’s role becomes even more pronounced when paired with high-performance cylinder heads, where precise fuel metering can significantly influence engine efficiency and power.

Injector plumbing is another component where the 5283275 injector plays a significant role. The plumbing system, which includes fuel lines and rails, must be compatible with the injector to ensure seamless fuel flow. Proper installation and maintenance of the injector within this system are essential for preventing fuel leaks and ensuring consistent fuel pressure.

When it comes to performance parts, the 5283275 injector is often a go-to component for enthusiasts looking to upgrade their engine. Its ability to deliver fuel with high precision makes it a valuable asset in performance-oriented engine builds. Whether it’s for increased horsepower, better fuel economy, or enhanced drivability, the injector’s role in these systems cannot be overstated.

Conclusion

Understanding the Cummins 5283275 injector and its role in commercial truck engines is essential for engineers, mechanics, truck drivers, and fleet operators. By mastering the concepts, troubleshooting techniques, and maintenance practices outlined in this article, professionals can ensure the longevity and efficiency of their truck engines, ultimately contributing to safer and more reliable operations.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Cummins Inc. (n.d.). About Cummins. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSG12 CM2350 G113. Bulletin Number 5467253.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.