Introduction to Doser Injectors

Doser injectors are critical in modern diesel engines, particularly in heavy-duty trucks. These components deliver fuel into the combustion chamber with precision, ensuring peak engine performance and efficiency. The Cummins 5305254 doser injector represents advanced fuel injection technology, designed to endure the rigorous demands of commercial truck operations 1.

How a Doser Injector Works

The operation of a doser injector relies on precise control of fuel quantity and injection timing. This is achieved through the integration of electronic control units (ECUs) and sophisticated hydraulic systems. The doser injector interprets signals from the engine control module (ECM), which determines the exact fuel amount to be injected based on engine load, speed, and other operational parameters. A solenoid within the injector controls the opening and closing of a nozzle, allowing fuel to be sprayed into the combustion chamber at the optimal moment 2.

Purpose of the Cummins 5305254 Doser Injector

The Cummins 5305254 doser injector is essential for the efficient operation of commercial trucks. Its primary function is to ensure the engine receives the correct fuel amount at the precise time, which is vital for maintaining power, efficiency, and reducing emissions. This doser injector is engineered to handle the high pressures and temperatures characteristic of heavy-duty engines, ensuring reliable performance even under the most strenuous conditions 3.

Role in Truck Operations

In truck operations, the doser injector is fundamental to the engine’s overall efficiency and performance. By delivering fuel with exceptional accuracy, it helps maximize fuel economy, reduce wear and tear on engine components, and minimize harmful emissions. This is particularly significant for fleet operators who must balance performance with cost-effectiveness and environmental responsibility.

Troubleshooting and Maintenance

Proper maintenance of the doser injector is crucial for its longevity and performance. Regular inspections should include checking for leaks, ensuring the nozzle is clean and free from deposits, and verifying that the solenoid is functioning correctly. Common troubleshooting steps include:

- Checking for Leaks: Inspect the injector for any signs of fuel leakage, which could indicate a faulty seal or nozzle.

- Cleaning the Nozzle: Deposits on the nozzle can impact fuel delivery. Regular cleaning with a suitable solvent can help maintain optimal performance.

- Testing the Solenoid: The solenoid controls the opening and closing of the injector. Using a multimeter, check the resistance and ensure it is within the specified range.

- Inspecting Electrical Connections: Ensure all electrical connections are secure and free from corrosion. Loose or damaged connections can lead to erratic injector operation.

Cummins: A Leader in Diesel Technology

Cummins is a distinguished name in the diesel engine industry, recognized for its innovation and dedication to quality. The company boasts a rich history of developing advanced engine technologies, including doser injectors, that enhance performance, efficiency, and reliability. Cummins’ expertise in diesel technology is supported by extensive research and development, ensuring that their products meet the highest standards of performance and durability.

Compatibility of Doser Injector Part 5305254 with Cummins Engines

The Doser Injector part 5305254, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s fuel injection system, ensuring precise fuel delivery and optimal engine performance. Below is a detailed overview of the engines with which this doser injector is compatible.

Compatible Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- ISB4.5 CM2350 B104

- QSB6.7 CM2350 B105

- QSF3.8 CM2350 F107

Grouping by Engine Series

B Series Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- ISB4.5 CM2350 B104

The B series engines, including the B4.5, B6.7, and ISB4.5, are known for their robust design and reliability. The Doser Injector part 5305254 is engineered to work seamlessly with these engines, ensuring efficient fuel delivery and maintaining the engine’s performance standards.

F Series Engines

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- QSF3.8 CM2350 F107

The F series engines, such as the F3.8, are designed for versatility and performance. The Doser Injector part 5305254 is specifically tailored to fit these engines, providing the necessary precision in fuel injection to enhance overall engine efficiency and power output.

QSB Series Engines

- QSB6.7 CM2350 B105

The QSB series engines, including the QSB6.7, are built for durability and high performance. The Doser Injector part 5305254 is compatible with these engines, ensuring that the fuel injection system operates smoothly and efficiently, contributing to the engine’s longevity and reliability.

Each of these engines benefits from the precise engineering of the Doser Injector part 5305254, which is crucial for maintaining the engine’s performance and efficiency.

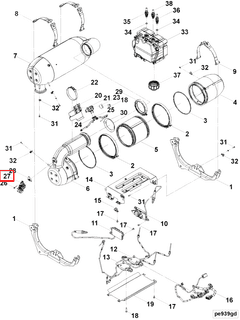

Role of Part 5305254 Doser Injector in Engine Systems

The Part 5305254 Doser Injector is an integral component within the aftertreatment arrangement of modern engine systems. Its primary function is to inject a precise amount of Diesel Exhaust Fluid (DEF) into the exhaust stream. This injection is vital for the operation of the Selective Catalytic Reduction (SCR) system, which is a key part of the aftertreatment device.

When the Doser Injector releases DEF into the exhaust, it mixes with the hot exhaust gases. This mixture then travels to the decomposition reactor, where the DEF decomposes into ammonia. The ammonia reacts with nitrogen oxides (NOx) in the exhaust, converting them into harmless nitrogen and water vapor. This process significantly reduces the emissions of NOx, ensuring the engine meets environmental regulations.

The efficiency of the Doser Injector directly influences the performance of the aftertreatment system. Accurate dosing ensures optimal reduction of NOx, maintaining the system’s effectiveness over time. The integration of the Doser Injector with the aftertreatment arrangement highlights its importance in achieving clean and efficient engine operation.

Conclusion

The Cummins 5305254 doser injector is a vital component in the operation of commercial trucks, ensuring that engines receive the precise amount of fuel needed for optimal performance. Understanding how this doser injector works, its role in truck operations, and the importance of proper maintenance can help engineers, mechanics, and fleet operators keep their vehicles in top condition. Cummins’ reputation for excellence in diesel technology underscores the reliability and effectiveness of their doser injectors.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011.

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.