This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

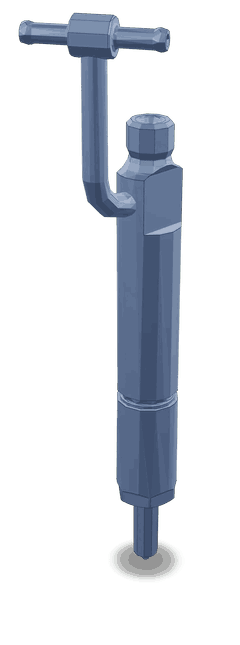

The Cummins 5367230 Injector is a specialized component designed for use in commercial trucks. It plays a role in the efficient operation of diesel engines by ensuring precise fuel delivery and enhancing combustion efficiency. Understanding its function and significance is key to maintaining and optimizing the performance of commercial vehicles.

Basic Concepts of Fuel Injectors

Fuel injectors are components that deliver fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air to create a combustible mixture. The efficiency of this process is vital for the engine’s performance, as it directly affects combustion efficiency, power output, and emissions. Modern fuel injectors, like the Cummins 5367230, utilize advanced technology to ensure precise fuel delivery under varying engine conditions 1.

Purpose of the Cummins 5367230 Injector

This Cummins part is designed to deliver fuel into the engine’s combustion chamber with precision. Its role is to atomize fuel efficiently, ensuring optimal mixing with air for combustion. This process is crucial for achieving high engine performance, fuel efficiency, and lower emissions. The injector’s design allows it to operate under high pressure, ensuring that fuel is delivered consistently and accurately across a wide range of engine speeds and loads 2.

Key Features

The Cummins 5367230 Injector boasts several key features that enhance its performance. Its design incorporates advanced materials and precision engineering to ensure durability and efficiency. The injector utilizes electronic controls for precise fuel delivery, adapting to engine conditions in real-time. Additionally, its construction includes features that reduce wear and improve longevity, making it a reliable component for commercial truck engines 3.

Benefits of Using the Cummins 5367230 Injector

Utilizing this part offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when and where it is needed. This precision also enhances engine performance, leading to increased power output and smoother operation. Furthermore, the injector’s design helps reduce emissions by promoting more complete combustion, which is beneficial for environmental compliance and operational efficiency 4.

Installation and Integration

Proper installation of the Cummins 5367230 Injector is crucial for ensuring its optimal performance. Installation procedures should follow manufacturer guidelines to ensure compatibility with the engine and to avoid damage. Considerations for engine type and condition are important to ensure that the injector operates efficiently within the specific engine environment. Compatibility with various engine types is a key factor in the injector’s design, allowing it to be integrated into a wide range of commercial truck applications.

Maintenance and Troubleshooting

Maintaining the Cummins 5367230 Injector is important for ensuring its longevity and performance. Regular inspection routines should be conducted to check for signs of wear or damage. Cleaning procedures may be necessary to remove any deposits that could affect the injector’s operation. Troubleshooting common issues, such as misfires or irregular engine performance, may involve checking the injector’s electrical connections, fuel supply, and internal components for any signs of malfunction.

Performance Enhancements

The Cummins 5367230 Injector contributes to overall engine performance in several ways. By ensuring precise fuel delivery, it helps achieve higher power output and improved fuel economy. The injector’s design also plays a role in reducing emissions, making it a valuable component for engines that must meet stringent environmental regulations. Its integration into the engine system enhances combustion efficiency, leading to smoother operation and reduced wear on engine components.

Technological Innovations

This Cummins part incorporates several technological innovations that enhance its performance. Precision engineering ensures that fuel is delivered with accuracy, while electronic controls allow for real-time adjustments to fuel delivery based on engine conditions. Durability enhancements in its construction make it resistant to the high pressures and temperatures encountered in diesel engines, ensuring long-term reliability.

Environmental Impact

The use of the Cummins 5367230 Injector has positive environmental implications. By promoting more complete combustion, it helps reduce emissions of harmful pollutants. Improved fuel efficiency also means that less fuel is consumed for the same amount of work, further reducing the environmental impact of commercial truck operations. These benefits are increasingly important as the industry moves towards more sustainable practices.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to sustainability, Cummins has established itself as a leader in the diesel engine and components industry. The company’s product range includes engines, filtration, emissions solutions, and power generation products, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Injector Part 5367230 Compatibility

The Cummins injector part number 5367230 is a critical component designed to work seamlessly with several engine models. This injector is engineered to deliver precise fuel injection, ensuring optimal performance and efficiency across various applications.

Engine Compatibility

- B3.3 Engine Series

- The injector part 5367230 is specifically designed to fit within the B3.3 engine series. This series is known for its reliability and efficiency, making it a popular choice in various industrial and commercial applications.

Application and Integration

The integration of the injector part 5367230 into the B3.3 engine series involves several key considerations:

- Precision Fitment: The injector is engineered to fit perfectly within the engine’s fuel injection system, ensuring that it can deliver fuel with the required precision and timing.

- Material and Durability: The injector is made from high-quality materials that can withstand the harsh conditions within the engine, ensuring longevity and consistent performance.

- Compatibility with Fuel Systems: The injector is designed to work with the specific fuel system of the B3.3 engine, ensuring that it can handle the fuel type and pressure requirements effectively.

Performance Benefits

- Enhanced Fuel Efficiency: By delivering fuel with high precision, the injector helps improve the engine’s fuel efficiency, reducing overall fuel consumption.

- Consistent Power Output: The injector ensures that the engine maintains consistent power output, which is crucial for applications that require reliable performance.

- Reduced Emissions: The precise fuel delivery helps in reducing harmful emissions, making the engine more environmentally friendly.

Installation and Maintenance

- Easy Installation: The injector is designed for easy installation, which can be performed by trained technicians without the need for specialized tools.

- Regular Maintenance: To ensure optimal performance, regular maintenance of the injector is recommended. This includes periodic inspections and cleaning to prevent any build-up that could affect its performance.

Role of Part 5367230 Injector in Engine Systems

The part 5367230 injector is an essential component in the fuel delivery system of an engine. Its primary function is to atomize and deliver fuel into the combustion chamber at precise moments, ensuring optimal fuel-air mixture for efficient combustion.

When the injector is activated by the engine control unit (ECU), it sprays a fine mist of fuel into the intake tract or directly into the combustion chamber, depending on whether the engine is port-fuel injected or direct-injected. This action is synchronized with the movement of the connecting rod and piston.

As the piston moves downward during the intake stroke, the intake valve opens, allowing the air-fuel mixture to enter the cylinder. The injector’s timing must be impeccable to ensure that the fuel is introduced just before the compression stroke begins. During the compression stroke, the connecting rod transfers the piston’s linear motion to the crankshaft, compressing the air-fuel mixture in preparation for ignition.

The injector’s role becomes even more significant in direct-injection systems, where it sprays fuel directly into the combustion chamber. This method allows for better fuel atomization and more precise control over the fuel-air mixture, leading to improved engine performance and efficiency.

In summary, the part 5367230 injector works in concert with the connecting rod and piston to ensure that the engine operates smoothly and efficiently. Its precise fuel delivery is a key factor in maintaining the correct fuel-air ratio, which is vital for optimal combustion and overall engine performance.

Conclusion

The Cummins 5367230 Injector is a critical component in the efficient operation of diesel engines, particularly in commercial trucks. Its precise fuel delivery, enhanced by advanced technology and precision engineering, contributes to improved fuel efficiency, engine performance, and reduced emissions. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its benefits and ensuring the longevity and reliability of commercial vehicle engines.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.