This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

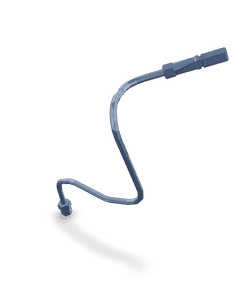

The Injector Fuel Supply Tube, identified by Part #5376886, is a component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This tube is integral to the fuel system of heavy-duty trucks, facilitating the efficient delivery of fuel from the tank to the injectors. Its role ensures that the engine receives a consistent and precise amount of fuel, which is vital for optimal performance and efficiency 1.

Function and Operation

The Injector Fuel Supply Tube operates by channeling fuel from the tank to the injectors within the engine. This process begins when the fuel pump draws fuel from the tank and sends it through the supply tube. The tube’s design allows for a steady flow of fuel, ensuring that the injectors receive the necessary amount to facilitate combustion. This consistent fuel delivery is essential for maintaining engine performance and efficiency 2.

Key Features

The Injector Fuel Supply Tube is constructed from high-quality materials that enhance its durability and performance. Its design includes features such as reinforced connections and a smooth interior to prevent fuel flow disruptions. These attributes contribute to the tube’s reliability and longevity, ensuring it can withstand the demanding conditions of heavy-duty truck operations 3.

Benefits

The Injector Fuel Supply Tube offers several advantages, including improved fuel efficiency and reliability. By ensuring a consistent fuel supply, it helps maintain engine performance and reduces the likelihood of fuel-related issues. Additionally, its compatibility with Cummins engines ensures that it integrates seamlessly into the fuel system, providing optimal performance and efficiency 4.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is vital for ensuring its effectiveness and longevity. It should be securely connected to both the fuel tank and the injectors to prevent leaks and ensure a consistent fuel flow. Regular maintenance, such as inspecting for wear and damage, is recommended to ensure optimal performance. Common troubleshooting tips include checking for leaks, ensuring secure connections, and verifying consistent fuel flow 5.

Safety Considerations

When handling and working with the Injector Fuel Supply Tube, it is important to follow safety precautions to prevent accidents. This includes ensuring that the fuel system is depressurized before beginning any work, using appropriate personal protective equipment, and following manufacturer guidelines for installation and maintenance. These precautions help ensure safe operation and prevent potential hazards 6.

Environmental Impact

The Injector Fuel Supply Tube contributes to reducing emissions and improving fuel economy. By ensuring a consistent and precise fuel delivery, it helps the engine operate more efficiently, which can lead to lower emissions. This aligns with environmental regulations and sustainability goals, making it a valuable component in the pursuit of greener transportation solutions 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Their product offerings include a wide range of engines and components designed to meet the demanding needs of various applications 8.

Conclusion

The Injector Fuel Supply Tube, part number 5376886, is a critical component in the fuel delivery system of several engines. Its design and placement are crucial for preventing fuel leaks and ensuring consistent fuel flow, which is essential for the engine’s performance and longevity. Proper installation, maintenance, and adherence to safety precautions are vital for ensuring the effectiveness and reliability of this Cummins part.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Karsten Berns et al., Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality, SAE International, 2012.

↩ -

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality, SAE International, 2012.

↩ -

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Karsten Berns et al., Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.