5481951

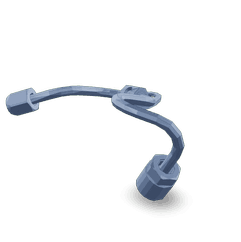

Injector Fuel Supply Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, identified by part number 5481951, is a critical component in the fuel delivery system of heavy-duty trucks. This tube facilitates the transport of fuel from the fuel tank to the injectors, ensuring a consistent and reliable supply that is vital for engine operation. Its role in maintaining the efficiency and performance of the engine underscores its significance within the fuel system.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a conduit designed to deliver fuel under pressure from the fuel tank to the injectors. This component is essential for the proper functioning of the fuel injection system, as it ensures that fuel is delivered at the correct pressure and volume to each injector. The tube’s design and material contribute to the overall performance of the engine by supporting efficient fuel delivery and combustion 1.

Purpose and Role in Truck Operation

The Cummins Injector Fuel Supply Tube plays a pivotal role in the operation of a truck by ensuring that fuel is delivered to the injectors in a controlled and precise manner. This delivery is fundamental to maintaining engine efficiency, as it allows for optimal combustion and power output. The tube’s function in the fuel system is to provide a reliable pathway for fuel, contributing to the engine’s overall performance and reliability 2.

Key Features

The Cummins Injector Fuel Supply Tube is characterized by several key features that enhance its performance and durability. Constructed from high-quality materials, the tube is designed to withstand the pressures and temperatures associated with fuel delivery in heavy-duty applications. Its design includes elements that ensure a secure fit within the fuel system, minimizing the risk of leaks and ensuring consistent fuel delivery 3.

Benefits

Utilizing the Cummins Injector Fuel Supply Tube offers several benefits, including improved fuel delivery efficiency, enhanced engine performance, and increased reliability in heavy-duty applications. The tube’s design and construction contribute to these advantages by ensuring a consistent and reliable fuel supply to the injectors, which is essential for maintaining engine efficiency and performance 4.

Installation and Compatibility

Proper installation of the Cummins Injector Fuel Supply Tube is crucial for ensuring its effectiveness and compatibility with various Cummins engine models. Installation procedures should follow manufacturer guidelines to ensure a secure and leak-free connection within the fuel system. Specific requirements or considerations for installation may vary depending on the engine model, highlighting the importance of adhering to recommended practices.

Maintenance and Troubleshooting

Maintaining the Cummins Injector Fuel Supply Tube is essential for ensuring optimal performance and longevity. Regular inspections for signs of wear, leaks, or damage are recommended to prevent potential issues. Common problems may include fuel leaks or reduced fuel delivery efficiency, which can often be addressed through proper maintenance and troubleshooting practices.

Performance and Efficiency

The Cummins Injector Fuel Supply Tube contributes to the overall performance and efficiency of the engine by ensuring a consistent and reliable fuel supply to the injectors. This consistent delivery supports efficient combustion, which is directly related to fuel economy, power output, and emissions control. The tube’s role in the fuel system is fundamental to achieving optimal engine performance.

Safety Considerations

Safety considerations related to the Cummins Injector Fuel Supply Tube include proper handling, installation, and maintenance practices. Ensuring that the tube is correctly installed and maintained can prevent accidents or malfunctions associated with fuel delivery. Adhering to safety guidelines and manufacturer recommendations is crucial for maintaining the integrity of the fuel system and ensuring safe operation.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality components for heavy-duty trucks. With a history of innovation and commitment to excellence, Cummins has established a reputation for producing reliable and durable parts that contribute to the performance and efficiency of engines. The company’s dedication to quality and customer satisfaction underscores its position as a leader in the industry.

Compatibility

The Injector Fuel Supply Tube, part number 5481951, is compatible with various Cummins engines, ensuring efficient and accurate fuel delivery to the injectors. This compatibility is crucial for maintaining the integrity of the fuel delivery system in these engines.

ISC Series Engines:

- ISC CM2150

- ISC8.3 CM2250

ISL Series Engines:

- ISL CM2150

- ISL9 CM2250

QSC and QSL Series Engines:

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

Role in Engine Systems

The Injector Fuel Supply Tube, identified by part number 5481951, is integral to the efficient operation of fuel injection systems in engines. This component is specifically designed to facilitate the precise delivery of fuel from the supply lines to the injectors, ensuring optimal performance and reliability.

Integration with Injector Plumbing

In the context of injector plumbing, the Injector Fuel Supply Tube serves as a vital conduit. It connects the high-pressure fuel supply to individual injectors, allowing for consistent fuel distribution. This setup is essential for maintaining the correct fuel pressure and flow rate, which are paramount for the injectors to atomize fuel effectively and promote efficient combustion.

Function within Injector Supply Plumbing

When considering injector supply plumbing, the Injector Fuel Supply Tube plays a key role in the overall fuel delivery network. It ensures that each injector receives a uniform supply of fuel, which is critical for balanced engine operation. The tube’s design minimizes pressure drops and fuel leakage, contributing to the system’s overall efficiency and reliability.

Role in General Plumbing Systems

In broader plumbing systems within the engine, the Injector Fuel Supply Tube acts as a bridge between the fuel supply and the injectors. Its precise engineering allows it to withstand high pressures and temperatures, ensuring durable performance over the engine’s lifespan. This component is also designed to facilitate easy maintenance and replacement, reducing downtime and enhancing serviceability.

Interaction with Injectors

Directly interfacing with the injectors, the Injector Fuel Supply Tube ensures that each injector operates within its specified parameters. This direct connection is essential for the injectors to deliver fuel in the exact quantities and at the precise moments required by the engine’s control unit, optimizing combustion efficiency and reducing emissions.

Application in XPI JV System Cummins MR

In the XPI JV System for Cummins MR engines, the Injector Fuel Supply Tube is a cornerstone component. It supports the system’s high-pressure fuel requirements, enabling the injectors to perform at their best. The tube’s robust construction and precise engineering are tailored to meet the demanding conditions of this advanced fuel injection system, ensuring reliable and efficient engine performance.

Conclusion

The Cummins Injector Fuel Supply Tube (Part #5481951) is a vital component in the fuel delivery system of heavy-duty trucks, ensuring efficient and reliable fuel supply to the injectors. Its compatibility with various Cummins engine models, coupled with its robust design and construction, contributes to enhanced engine performance, efficiency, and reliability. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this component.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.