This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

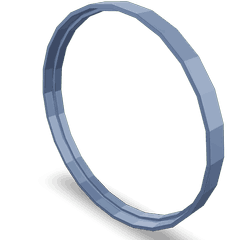

Understanding The Cummins 3377118 Counterbore Insert

Introduction

Counterbore inserts are essential for the functionality and durability of commercial truck engines. These components ensure precise fits and secure connections within engine assemblies. Among the various counterbore inserts available, the Cummins 3377118 stands out for its exceptional quality and performance. This article explores the specifics of this Cummins part, examining its function, integration into engine systems, and best practices for maintenance.

Basic Concepts Related To Counterbore Inserts

A counterbore insert is a precision-machined component designed to create a specific diameter and depth within a pre-drilled hole. Its primary function is to provide a secure seating area for fasteners, ensuring that bolts and screws are properly aligned and tightened. In engine components, counterbore inserts are crucial for maintaining structural integrity and preventing leaks. The precision and material quality of these inserts are paramount, as even minor deviations can lead to significant issues in high-stress environments 1.

Purpose Of The Cummins 3377118 Counterbore Insert

The Cummins 3377118 is specifically engineered to enhance the performance and longevity of Cummins engines. This insert is designed to fit into designated areas within the engine block or cylinder head, providing a secure and precise seating for critical fasteners. By ensuring proper alignment and fit, the 3377118 contributes to the overall stability and efficiency of the engine. Its applications are diverse, ranging from securing cylinder head bolts to supporting various engine mounts and brackets.

Cummins: A Leader In Engine Manufacturing

Cummins is renowned for its commitment to quality and innovation in engine manufacturing. The company’s reputation is built on a legacy of producing reliable and high-performance engine components. Using genuine Cummins parts, such as the 3377118, ensures optimal performance and reliability. Cummins’ dedication to precision engineering and material science is evident in every component they produce, making their parts a preferred choice among professionals in the industry 2.

Troubleshooting And Maintenance Of The 3377118 Counterbore Insert

While the Cummins 3377118 is designed for durability, it is not immune to issues. Common problems include corrosion, wear, and improper seating, which can lead to leaks or fastening failures. To troubleshoot these issues, it is essential to conduct regular inspections and follow a systematic approach to identify the root cause. Maintenance tips include cleaning the insert and surrounding areas, ensuring proper torque settings during installation, and replacing the insert if signs of wear or damage are detected. Adhering to manufacturer guidelines for inspection and maintenance is crucial for ensuring the longevity and effectiveness of the insert 3.

Expert Insights And Best Practices

Industry experts emphasize the importance of using high-quality counterbore inserts and following best practices for installation and replacement. When installing a counterbore insert, it is vital to ensure that the surrounding area is clean and free of debris. Using the correct tools and torque settings is essential to avoid over-tightening or under-tightening, which can compromise the insert’s integrity. Additionally, experts recommend periodic inspections to catch any signs of wear early and prevent premature failure.

Real-World Applications And Case Studies

The Cummins 3377118 has been successfully implemented in various commercial truck engines, demonstrating its reliability and performance. Case studies have shown that using high-quality counterbore inserts can significantly reduce maintenance costs and enhance engine longevity. For instance, fleets that have adopted Cummins counterbore inserts have reported fewer instances of fastening failures and leaks, leading to improved operational efficiency and reduced downtime.

Conclusion

In conclusion, the Cummins 3377118 Counterbore Insert is a critical component in the maintenance and performance of Cummins engines. Its precise design and high-quality materials ensure secure fastening and long-lasting performance. Regular maintenance, adherence to manufacturer guidelines, and the use of genuine Cummins parts are essential for maximizing the benefits of this insert. For any specific concerns or questions, consulting with Cummins-certified technicians is recommended to ensure optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.