This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

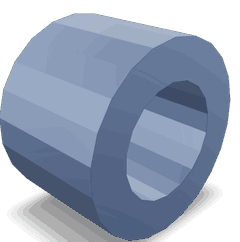

The Cummins 3044140 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine and drivetrain to the truck’s frame and cabin. Its role is significant in ensuring the smooth operation and comfort of commercial trucks.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between two surfaces. They function by absorbing or dampening the vibrational energy, thereby minimizing its impact on connected components. In mechanical systems, particularly heavy-duty trucks, vibration isolators play a vital role in maintaining operational efficiency and comfort. They help in reducing the wear and tear on various components and contribute to a smoother ride for both the driver and passengers 1.

Purpose of the 3044140 Vibration Isolator

The 3044140 Vibration Isolator is specifically designed to reduce vibrations transmitted from the engine and drivetrain to the truck’s frame and cabin. By doing so, it helps in maintaining the structural integrity of the truck and enhances the comfort levels inside the cabin. This reduction in vibration also contributes to the longevity of the truck’s components by minimizing the stress and wear they undergo 2.

Key Features

The 3044140 Vibration Isolator boasts several key features that enhance its performance. Its design incorporates materials that are resilient to the harsh conditions typically encountered in commercial trucking. The isolator is engineered to withstand significant vibrational forces while maintaining its effectiveness over time. Additionally, it features a robust construction that ensures durability and reliability in various operating environments 3.

Benefits of Using the 3044140 Vibration Isolator

Incorporating the 3044140 Vibration Isolator into truck designs offers several advantages. It contributes to improved ride comfort by reducing the vibrations felt inside the cabin. This enhancement in comfort can lead to increased driver satisfaction and productivity. Furthermore, by minimizing vibrations, the isolator helps in reducing wear and tear on truck components, which can lead to lower maintenance costs and extended component lifespan. The enhanced driving experience also plays a role in attracting and retaining skilled drivers 4.

Installation and Integration

Proper installation and integration of the 3044140 Vibration Isolator are crucial for its optimal performance. It should be mounted correctly within the truck’s system, ensuring that it is aligned properly with the engine and drivetrain components. Attention to detail during installation helps in maximizing the isolator’s effectiveness in reducing vibrations and ensuring the smooth operation of the truck.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the longevity and efficient operation of the 3044140 Vibration Isolator. Common issues may include wear and tear or misalignment, which can be addressed through periodic inspections and adjustments. Maintenance tips include checking for signs of damage or excessive wear, ensuring proper alignment, and replacing the isolator if it shows significant signs of degradation.

Performance and Efficiency

The 3044140 Vibration Isolator contributes to the overall performance and efficiency of a truck in several ways. By reducing vibrations, it helps in maintaining the structural integrity of the truck, which can lead to improved fuel efficiency and reduced maintenance costs. The isolator also plays a role in extending the lifespan of various truck components by minimizing the stress they undergo due to vibrations.

Cummins Corporation

Cummins Corporation is a leading manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation and quality. With a rich history of producing reliable and high-performance components, Cummins plays a significant role in enhancing the efficiency and reliability of commercial trucks. The company’s dedication to advancing technology and maintaining high standards in manufacturing ensures that its products, like the 3044140 Vibration Isolator, meet the demanding requirements of the trucking industry.

Role of Part 3044140 Vibration Isolator in Engine Systems

The 3044140 Vibration Isolator is an essential component in maintaining the stability and efficiency of various engine systems. It effectively mitigates the transmission of vibrations from the engine to other sensitive components, ensuring optimal performance and longevity.

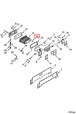

Integration with Lubricating Oil System

In the lubricating oil system, the Vibration Isolator plays a significant role by stabilizing the oil filter and the lubricating oil assembly. By reducing vibrations, it helps maintain a consistent flow of oil, which is vital for the proper lubrication of engine parts. This stability ensures that the oil filter can effectively remove contaminants from the lubricating oil, thereby protecting critical engine components from wear and tear 5.

Enhancing Lubricating Oil Assembly Cooler Performance

The lubricating oil assembly cooler is another component that benefits from the Vibration Isolator. By minimizing vibrations, the isolator helps maintain the structural integrity of the cooler, allowing it to efficiently dissipate heat from the lubricating oil. This results in better temperature regulation of the oil, which is essential for maintaining viscosity and ensuring that the oil retains its lubricating properties under varying operating conditions 6.

Supporting Oil Cooler Efficiency

Similarly, the oil cooler relies on the Vibration Isolator to operate efficiently. Vibrations can cause misalignment or damage to the oil cooler, leading to reduced cooling efficiency. The isolator ensures that the oil cooler remains stable, allowing it to effectively transfer heat away from the lubricating oil and maintain optimal oil temperature. This, in turn, contributes to the overall reliability and performance of the engine system 7.

Conclusion

The 3044140 Vibration Isolator is a critical component in the maintenance and efficiency of commercial trucks and engine systems. By effectively managing vibrations, it enhances ride comfort, reduces wear and tear on components, and contributes to the overall performance and longevity of the truck and its engine systems.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.