This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3930198 Noise Isolator is a component designed to mitigate noise levels in commercial truck operations. Its purpose is to enhance the driving experience by reducing the noise generated by the engine and drivetrain. This isolator contributes to a quieter cabin environment, which can improve driver comfort and potentially increase operational efficiency 1.

Basic Concepts of Noise Isolators

A noise isolator is a device that reduces the transmission of sound or vibration from one part of a mechanical system to another. It functions by absorbing, reflecting, or redirecting sound waves and vibrations. The general principles behind noise reduction involve dampening the energy that causes noise, thereby minimizing its impact on the surrounding environment 2.

Purpose of the 3930198 Noise Isolator

The 3930198 Noise Isolator plays a role in the operation of a truck by reducing engine and drivetrain noise. It is positioned to intercept and mitigate the vibrations and sound waves produced by these components, thereby contributing to a quieter cabin environment. This reduction in noise can lead to a more comfortable driving experience and may also have implications for the overall operational smoothness of the vehicle 3.

Key Features

The 3930198 Noise Isolator incorporates several key features that enhance its effectiveness. These include a material composition designed to absorb and dampen vibrations, a design that allows for optimal noise reduction, and technological innovations that improve its performance. The isolator is engineered to be durable and efficient, ensuring long-term reliability in demanding commercial truck applications 4.

Benefits of Using the 3930198 Noise Isolator

The advantages provided by the 3930198 Noise Isolator include improved driver comfort due to reduced cabin noise. This can lead to less fatigue during long drives, potentially enhancing safety and productivity. Additionally, the reduction in noise may contribute to increased operational efficiency by creating a more pleasant working environment for the driver 1.

Installation Process

Proper installation of the 3930198 Noise Isolator involves several steps. It begins with ensuring the truck is safely supported and the engine is turned off. The isolator should be positioned according to the manufacturer’s guidelines, using any required tools or additional components to secure it in place. Careful attention to detail during installation ensures optimal performance and longevity of the isolator 2.

Maintenance and Troubleshooting

Regular maintenance practices for the 3930198 Noise Isolator include periodic inspections for signs of wear or damage. Troubleshooting common issues may involve checking for proper installation, ensuring all connections are secure, and addressing any unusual noises or vibrations that could indicate a problem with the isolator 3.

Performance Impact

The 3930198 Noise Isolator affects the overall performance and efficiency of the truck by reducing noise levels and contributing to operational smoothness. The decrease in cabin noise can lead to a more comfortable driving environment, potentially reducing driver fatigue and enhancing overall productivity 4.

Compatibility and Applications

The 3930198 Noise Isolator is designed for use with specific types of trucks and engine models. It is particularly beneficial in applications where noise reduction is a priority, such as long-haul trucking or urban delivery services. Its compatibility ensures it can be effectively integrated into various commercial truck setups 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s products, including the 3930198 Noise Isolator, are designed to meet the demanding requirements of commercial applications, ensuring reliability and performance 2.

Noise Isolator 3930198 Compatibility with Cummins Engines

The Cummins Noise Isolator part number 3930198 is designed to fit a range of Cummins engines, providing effective noise reduction and enhancing the overall operational environment. This part is compatible with the following engines:

Cummins 6B5.9 and 6C8.3 Engines

The 3930198 Noise Isolator is engineered to fit seamlessly with the Cummins 6B5.9 and 6C8.3 engines. These engines are known for their reliability and performance, and the noise isolator ensures that the operational noise is minimized, contributing to a quieter and more comfortable working environment 3.

Cummins ISC CM554 and QSC8.3 CM554 Engines

Similarly, the Cummins ISC CM554 and QSC8.3 CM554 engines benefit from the installation of the 3930198 Noise Isolator. These engines are widely used in various applications, from construction to agricultural machinery, and the noise isolator helps in reducing the noise levels, making the operation more pleasant and less stressful for the operators 4.

The noise isolator is designed to be a straightforward addition to these engines, requiring minimal adjustments or modifications to the existing setup. It is crafted to provide optimal performance and durability, ensuring that it meets the rigorous demands of these engines.

Role of Part 3930198 Noise Isolator in Engine Systems

The 3930198 Noise Isolator is a component in mitigating unwanted vibrations and noise within engine systems. When integrated with various engine components, it significantly enhances the overall performance and longevity of the engine.

Integration with Mounting Components

When the Noise Isolator is installed alongside mounting components, it effectively reduces the transmission of engine vibrations to the vehicle’s chassis. This results in a smoother operation and decreased wear on both the engine and the mounting brackets. The isolator absorbs and dampens vibrations, ensuring that the engine remains securely mounted without excessive movement 1.

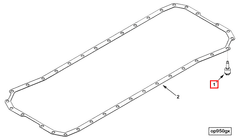

Interaction with Oil Pan and Pan Components

In conjunction with the oil pan and other pan components, the Noise Isolator plays a key role in maintaining a stable oil supply. By minimizing vibrations, it prevents the oil pan from resonating, which could otherwise lead to oil sloshing. This ensures a consistent oil flow to critical engine parts, promoting efficient lubrication and cooling. The isolator also helps in reducing the noise generated by the oil pan, contributing to a quieter engine operation 2.

Coordination with Oil System

The Noise Isolator works in harmony with the oil system to enhance engine performance. By stabilizing the engine and reducing vibrations, it allows the oil pump to operate more efficiently. This leads to better oil circulation and pressure maintenance, which is vital for the lubrication of moving parts such as pistons, bearings, and camshafts. The result is reduced friction and wear, leading to improved engine reliability and performance 3.

Conclusion

The Cummins 3930198 Noise Isolator is a vital component in enhancing the operational environment of commercial trucks. By effectively reducing engine and drivetrain noise, it contributes to improved driver comfort and operational efficiency. Its compatibility with various Cummins engines ensures it can be integrated into a wide range of applications, making it a valuable addition to any commercial truck setup 4.

-

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ ↩ ↩ ↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ ↩ ↩ ↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ ↩ ↩ ↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.