This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

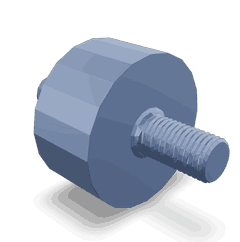

The Cummins 3973550 Vibration Isolation System is a component designed to reduce the transmission of vibrations from the engine to the truck’s frame and other components. This system plays a significant role in maintaining the operational efficiency and comfort levels in heavy-duty truck operations.

Basic Concepts of Vibration Isolation Systems

Vibration isolation systems are designed to minimize the transfer of vibrations generated by the engine to other parts of the vehicle. These systems typically use materials and designs that absorb, dampen, or redirect vibrations, thereby reducing their impact on the vehicle’s structure and components. In commercial trucks, effective vibration isolation contributes to improved engine performance, extended component lifespan, and enhanced driver and passenger comfort 1.

Purpose of the Cummins 3973550 Vibration Isolation System

The Cummins 3973550 Vibration Isolation System is engineered to mitigate the vibrations produced by the engine. This reduction in vibration can lead to more stable engine performance, decreased wear on truck components, and a smoother ride for the driver. By isolating vibrations, the system helps maintain engine efficiency and contributes to overall driver comfort.

Key Features

The Cummins 3973550 Vibration Isolation System incorporates several key features that enhance its performance. These include a composition of high-quality materials that provide effective vibration dampening, a design that ensures optimal integration with the truck’s engine and frame, and technological advancements that improve its durability and efficiency. These features work together to deliver reliable vibration isolation.

Benefits

The Cummins 3973550 Vibration Isolation System offers several benefits. It contributes to improved engine longevity by reducing the stress vibrations place on engine components. Additionally, it enhances driver comfort by minimizing the vibrations felt in the cab. Furthermore, by isolating vibrations, the system helps reduce wear on various truck components, leading to lower maintenance costs and increased vehicle reliability.

Installation Process

Installing the Cummins 3973550 Vibration Isolation System involves several steps to ensure proper integration with the truck’s engine and frame. The process includes preparing the installation area, positioning the isolation system correctly, securing it in place, and conducting tests to confirm its effectiveness. Following best practices during installation, such as using the correct tools and ensuring all connections are secure, can help prevent potential issues and ensure the system functions as intended.

Troubleshooting Common Issues

Common issues with the Cummins 3973550 Vibration Isolation System may include reduced effectiveness in vibration isolation, physical damage to the system, or improper installation. Troubleshooting these issues involves inspecting the system for signs of wear or damage, ensuring all connections are secure, and verifying that the system is correctly installed. Addressing these issues promptly can help maintain the system’s performance and longevity.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3973550 Vibration Isolation System, regular maintenance is recommended. This includes conducting routine inspections to check for signs of wear or damage, cleaning the system to remove any debris that may affect its performance, and following the manufacturer’s recommended service intervals for more comprehensive maintenance. Adhering to these maintenance practices can help prevent issues and ensure the system continues to provide effective vibration isolation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins offers a wide range of products designed to meet the needs of various industries, including automotive, construction, and agriculture. The company’s dedication to advancing technology and improving efficiency is evident in its diverse product lineup and ongoing research and development efforts.

Application of the 3973550 Vibration Isolation System

The 3973550 Vibration Isolation System, manufactured by Cummins, is designed to mitigate the effects of engine vibrations in various engine models. This part is crucial for maintaining the operational integrity and longevity of the engines by reducing the transmission of vibrations to the engine mounts and other components.

Application in A1400 and A1700 Engines

The A1400 and A1700 engines benefit significantly from the installation of the 3973550 Vibration Isolation System. These engines, known for their robust performance, can experience considerable vibrations during operation. The isolation system helps in dampening these vibrations, ensuring smoother operation and reducing wear and tear on engine components. By effectively isolating the engine from the chassis, it enhances the overall reliability and efficiency of these engines.

Application in A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines also integrate the 3973550 Vibration Isolation System to manage the inherent vibrations produced during their operation. These engines, which are typically used in heavy-duty applications, require a reliable system to handle the high levels of vibration. The isolation system ensures that the vibrations are minimized, thereby protecting the engine and its components from potential damage. This results in improved performance and a longer service life for the engines.

Grouping for Efficiency

The use of the 3973550 Vibration Isolation System across the A1400, A1700, A2000, and A2300 engines highlights its versatility and effectiveness in managing engine vibrations. By grouping these engines together, it becomes evident that the system is designed to cater to a range of engine sizes and power outputs, providing a consistent solution for vibration management. This approach ensures that operators of these engines can rely on a single, effective solution for maintaining their equipment.

Integration of 3973550 Vibration Isolation System with Engine Components

The 3973550 Vibration Isolation System is designed to enhance the performance and longevity of various engine components by effectively mitigating vibrations. When integrated with the radiator, this system plays a significant role in maintaining the radiator’s structural integrity and operational efficiency.

Radiator

The radiator is a vital component in the engine’s cooling system, responsible for dissipating heat from the engine coolant. Vibrations from the engine can lead to stress on the radiator, potentially causing leaks or structural damage over time. The 3973550 Vibration Isolation System reduces these vibrations, ensuring that the radiator remains stable and functions optimally. This stability is essential for consistent coolant flow and efficient heat exchange, directly contributing to the engine’s overall cooling performance.

By minimizing vibrations, the system also helps in preserving the seals and connections within the radiator, reducing the likelihood of coolant leaks. This not only enhances the radiator’s durability but also ensures that the engine maintains its optimal operating temperature, thereby improving its efficiency and reliability 2.

Conclusion

The Cummins 3973550 Vibration Isolation System is a vital component in heavy-duty truck operations, designed to reduce engine vibrations and enhance both engine performance and driver comfort. Its key features, benefits, and applications across various Cummins engines demonstrate its effectiveness in maintaining operational efficiency and component longevity. Regular maintenance and proper installation are essential to ensure the system’s optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.