This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3978359 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame. This isolator plays a role in maintaining the structural integrity and operational efficiency of commercial trucks by reducing the impact of engine vibrations 3.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from a source to its surroundings. They function by absorbing or dampening vibrations, thereby minimizing their impact on connected components. In the context of commercial trucks, vibration isolators help in maintaining the comfort of the ride, protecting sensitive equipment from damage, and enhancing the overall performance and longevity of the vehicle 1.

Purpose of the 3978359 Vibration Isolator

The Cummins 3978359 Vibration Isolator is specifically designed to reduce the vibrations generated by the engine, which can otherwise be transmitted to the truck’s frame and other components. By isolating these vibrations, the isolator contributes to a smoother ride, reduces stress on the truck’s structure, and helps in maintaining the efficiency and reliability of the vehicle 3.

Key Features

The Cummins 3978359 Vibration Isolator is characterized by its robust material composition, which includes high-quality rubber and metal components. Its design incorporates features that enhance its durability and effectiveness in vibration reduction. Unique characteristics of this isolator include its precise engineering to fit specific truck models and its ability to withstand the harsh conditions typical of commercial truck operations 2.

Benefits

The advantages of using the Cummins 3978359 Vibration Isolator include improved ride comfort for both the driver and passengers, reduced wear and tear on the truck’s components due to minimized vibrations, and enhanced overall performance of the vehicle. Additionally, by reducing vibrations, this isolator contributes to the longevity of the truck’s engine and other mechanical parts 3.

Installation Process

Installing the Cummins 3978359 Vibration Isolator involves several steps to ensure a secure and effective fit. The process includes preparing the mounting area, aligning the isolator with the engine and frame, and using the appropriate tools to fasten it in place. Best practices for installation include checking for proper alignment and ensuring that all fasteners are tightened to the manufacturer’s specifications 2.

Troubleshooting Common Issues

Common issues with the Cummins 3978359 Vibration Isolator may include excessive vibration or noise, which can indicate a problem with the isolator’s fit or condition. Troubleshooting steps involve inspecting the isolator for signs of wear or damage, ensuring it is properly installed, and addressing any issues with the engine or frame that may be contributing to the problem 1.

Maintenance Tips

Routine maintenance of the Cummins 3978359 Vibration Isolator is important for ensuring its optimal performance and longevity. Maintenance tips include regular inspection for signs of wear or damage, cleaning the isolator and its mounting area to remove dirt and debris, and replacing the isolator if it shows significant signs of wear or fails to effectively reduce vibrations 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company is renowned for its commitment to customer satisfaction and the durability and performance of its products 3.

Vibration Isolator Part 3978359 in Cummins Engines

The Vibration Isolator part 3978359, manufactured by Cummins, is a component in several of their engine models. This part is designed to mitigate the vibrations that can occur during engine operation, ensuring smoother performance and reducing wear on engine components 3.

K19 Engine Series

In the K19 engine series, the Vibration Isolator part 3978359 is integral to maintaining engine stability and longevity. It is strategically placed to absorb and dampen the vibrations generated by the engine, which helps in minimizing the transfer of these vibrations to the engine mounts and the vehicle chassis. This is particularly important in heavy-duty applications where engine vibrations can be more pronounced 3.

Cummins Engine Group

Across various Cummins engine groups, the Vibration Isolator part 3978359 serves a similar purpose. It is engineered to fit seamlessly into the engine’s design, providing a reliable barrier against the disruptive forces of engine vibrations. This ensures that the engine operates within optimal parameters, enhancing overall performance and reliability 3.

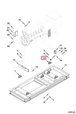

Role of Part 3978359 Vibration Isolator in Engine Systems

In engine systems, the 3978359 Vibration Isolator is instrumental in ensuring smooth operation by mitigating vibrations that can arise from various sources. When integrated with the rail and base components, this isolator significantly enhances the stability and efficiency of the engine 3.

Integration with the Rail

The rail in an engine system serves as a structural support and a pathway for various components. When the 3978359 Vibration Isolator is mounted on the rail, it effectively dampens the vibrations transmitted through this structure. This reduction in vibration not only prolongs the lifespan of the rail but also ensures that other components attached to it operate within optimal parameters. The isolator’s ability to absorb and dissipate vibrational energy helps maintain consistent performance and reduces the risk of mechanical wear 1.

Interaction with the Base

The base of an engine system provides the foundational support necessary for mounting and securing various engine components. By incorporating the 3978359 Vibration Isolator between the engine and the base, the transmission of vibrational forces to the base is significantly minimized. This isolation prevents the base from experiencing undue stress, which could lead to structural fatigue or failure over time. Additionally, a stable base ensures that the engine remains securely positioned, contributing to overall system reliability and performance 2.

Conclusion

The Cummins 3978359 Vibration Isolator plays a significant role in enhancing the operational integrity of engine systems by effectively managing vibrations in conjunction with the rail and base components. Its robust design and precise engineering contribute to the longevity and performance of commercial trucks, making it a valuable component in Cummins’ engine lineup 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.