This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4099188 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. Its role is significant in ensuring the smooth operation of commercial trucks, contributing to both the longevity of the vehicle and the comfort of its occupants.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between two surfaces. They function by absorbing and dampening the vibrational energy, thereby minimizing its impact on connected components. In mechanical systems, particularly heavy-duty trucks, vibration isolators play a vital role in maintaining the integrity and performance of various parts. They help in preserving the structural integrity of the truck’s frame, reducing wear and tear on components, and enhancing overall operational efficiency 1.

Purpose of the 4099188 Vibration Isolator

The 4099188 Vibration Isolator is specifically designed to reduce the vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, ensuring that the vibrations do not lead to premature wear or failure of critical components. Additionally, it contributes to a smoother ride, enhancing the comfort of the driver and passengers.

Key Features

The 4099188 Vibration Isolator is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typically encountered in commercial trucking, ensuring durability and reliability. The isolator’s design incorporates features that enhance its vibration dampening capabilities, providing effective isolation even under heavy loads or rough road conditions.

Benefits of Using the 4099188 Vibration Isolator

Incorporating the 4099188 Vibration Isolator in truck designs offers several advantages. It contributes to improved ride comfort by reducing the vibrations felt by the occupants. Additionally, it helps in reducing wear and tear on truck components, leading to lower maintenance costs and extended component lifespan. The isolator also plays a role in enhancing engine performance by ensuring that the engine operates in a stable environment, free from excessive vibrations 2.

Installation Process

Installing the 4099188 Vibration Isolator involves several steps to ensure proper fitting and functionality. The process requires specific tools and equipment, and it is important to observe safety precautions throughout. The isolator should be securely mounted between the engine and the truck’s frame, ensuring that it is properly aligned and tightened to the manufacturer’s specifications.

Troubleshooting Common Issues

Common problems associated with vibration isolators may include signs of wear or failure, such as cracks, deformation, or excessive movement. Troubleshooting steps may involve inspecting the isolator for visible signs of damage, checking its mounting for proper alignment and tightness, and ensuring that it is functioning as intended. Addressing these issues promptly can help in maintaining the isolator’s effectiveness and the overall performance of the truck.

Maintenance Tips

Regular maintenance of the 4099188 Vibration Isolator is important to ensure its longevity and optimal performance. This may involve periodic inspections for signs of wear or damage, ensuring that its mounting remains secure and properly aligned, and addressing any issues promptly. Following the manufacturer’s recommended maintenance schedule can help in preserving the isolator’s effectiveness and contributing to the overall reliability of the truck.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history of innovation and a commitment to quality, Cummins plays a significant role in the automotive industry, particularly in the production of reliable and efficient diesel engines and components for commercial vehicles 3.

Cummins Vibration Isolator 4099188 Compatibility

The Cummins Vibration Isolator part number 4099188 is designed to fit seamlessly with a range of Cummins engines, providing essential vibration damping and noise reduction. This part is crucial for maintaining the operational integrity and longevity of the engines by mitigating the adverse effects of vibrations.

QSK19 CM850 MCRS, QSK50 CM2150 MCRS, and QSK60 CM850 MCRS

The QSK19 CM850 MCRS, QSK50 CM2150 MCRS, and QSK60 CM850 MCRS engines benefit significantly from the installation of the 4099188 Vibration Isolator. These engines, known for their robust performance and reliability, are often used in heavy-duty applications where vibration control is critical. The isolator ensures that the engines operate smoothly, reducing wear and tear on engine components and enhancing overall performance.

VTA903 CM2250 V105

The VTA903 CM2250 V105 engine also integrates the 4099188 Vibration Isolator effectively. This engine, designed for high-performance applications, requires precise vibration management to maintain efficiency and reduce operational noise. The isolator plays a pivotal role in achieving these objectives, ensuring that the engine runs at optimal levels and extends its service life.

By incorporating the 4099188 Vibration Isolator into these engines, users can expect improved operational stability, reduced maintenance needs, and enhanced performance across various demanding applications.

Role of Part 4099188 Vibration Isolator in Engine Systems

The 4099188 Vibration Isolator is an essential component in mitigating the transmission of vibrations from the engine to various connected systems and accessories. By effectively dampening these vibrations, it ensures the smooth operation and longevity of several engine-related components.

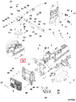

Integration with Engine Systems

-

Accessories: The Vibration Isolator helps in stabilizing accessories attached to the engine, such as alternators and power steering pumps, by reducing the vibrational forces that could otherwise lead to premature wear or failure.

-

Electric Starting System: For the starting motor and its associated components, the isolator plays a role in maintaining consistent performance. It prevents excessive vibrations from affecting the starter motor’s engagement with the flywheel, ensuring reliable starts.

-

Heat Exchanger and Thermostat Housing: In the engine cooling system, the isolator assists in protecting the heat exchanger and thermostat housing from vibrational stress. This protection is vital for maintaining the integrity of the cooling passages and ensuring efficient heat transfer.

-

Engine Control Module (ECM): The ECM, which is sensitive to physical disturbances, benefits from the isolator by operating in a more stable environment. This stability is important for accurate sensor readings and reliable engine management.

-

Auxiliary Cooling System: Components within the auxiliary cooling system, such as additional radiators or cooling fans, are less prone to vibrational damage when the isolator is in place. This results in maintained efficiency and prolonged system lifespan.

-

Engine Cooling System: The overall engine cooling system, including the expansion tank, relies on the isolator to prevent vibrations from causing leaks or structural weaknesses in the cooling lines and radiator.

By incorporating the 4099188 Vibration Isolator into these systems, engineers and mechanics can enhance the durability and performance of the engine and its interconnected components.

Conclusion

The Cummins 4099188 Vibration Isolator plays a crucial role in the smooth operation and longevity of commercial trucks. By effectively dampening vibrations transmitted from the engine to the truck’s frame and other components, it ensures the structural integrity of the vehicle, reduces wear and tear on components, and enhances overall operational efficiency. Regular maintenance and prompt troubleshooting of common issues are essential to preserving the isolator’s effectiveness and contributing to the overall reliability of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.