This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4324255 Vibration Isolator is a component designed to mitigate mechanical vibrations in commercial truck operations. Its purpose is to enhance the stability and comfort of the vehicle by reducing the transmission of vibrations from the engine and drivetrain to the truck’s frame and cabin.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations between components. They function by absorbing or dampening vibrational energy, thereby minimizing its impact on connected parts. In the context of trucks and other heavy-duty vehicles, vibration isolators play a role in maintaining the integrity of the vehicle’s structure and improving the comfort of the ride for occupants 1.

Purpose of the 4324255 Vibration Isolator

The Cummins 4324255 Vibration Isolator serves a specific role in the operation of a truck by reducing mechanical vibrations generated by the engine and drivetrain. This reduction helps in maintaining the structural integrity of the truck, enhancing driver and passenger comfort, and prolonging the lifespan of various components by minimizing wear and tear caused by excessive vibrations.

Key Features

The Cummins 4324255 Vibration Isolator is characterized by several primary features that enhance its performance. These include a robust material composition designed to withstand the rigors of heavy-duty truck operations, a design that effectively absorbs and dampens vibrations, and unique attributes that ensure compatibility and ease of installation within Cummins engine systems.

Benefits of Using the 4324255 Vibration Isolator

Incorporating the Cummins 4324255 Vibration Isolator into truck systems offers several advantages. These include improved comfort for drivers and passengers by reducing the transmission of vibrations, reduced wear and tear on truck components leading to lower maintenance costs, and enhanced overall performance of the vehicle by ensuring stable operation of the engine and drivetrain 2.

Installation Considerations

Proper installation of the Cummins 4324255 Vibration Isolator is crucial for its effective operation. Guidelines for installation include ensuring the truck is on a level surface, using the appropriate tools for securing the isolator, and following manufacturer recommendations for torque specifications. Special attention should be given to aligning the isolator correctly to ensure optimal vibration absorption.

Troubleshooting Common Issues

Common problems associated with vibration isolators may include reduced effectiveness over time due to wear, improper installation leading to inadequate vibration absorption, or damage to the isolator itself. Troubleshooting steps may involve inspecting the isolator for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary to restore optimal performance.

Maintenance Tips

Regular maintenance of the Cummins 4324255 Vibration Isolator is important for ensuring its longevity and optimal performance. Maintenance recommendations include periodic inspection for signs of wear or damage, cleaning the isolator to remove any debris that may affect its operation, and following manufacturer guidelines for replacement intervals to prevent failure due to excessive wear.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry, offering a comprehensive range of products designed to meet the demanding requirements of heavy-duty applications 3.

Vibration Isolator 4324255 for Cummins Engines

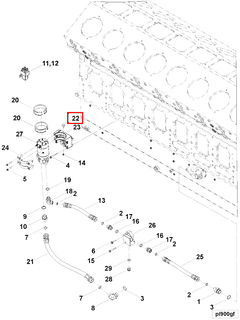

The Vibration Isolator part number 4324255 is a component designed to mitigate the effects of engine vibrations in various Cummins engine models. This part is specifically engineered to fit seamlessly within the engine architecture of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines.

In the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Vibration Isolator 4324255 is strategically positioned to absorb and dampen the vibrations generated during engine operation. This helps in maintaining the structural integrity of the engine and its surrounding components, thereby extending the overall lifespan of the engine.

The installation of this vibration isolator is crucial for ensuring smooth engine performance and reducing wear and tear on engine mounts and other critical parts. Its design allows it to effectively isolate the engine from the chassis, minimizing the transmission of vibrations to the vehicle or machinery it powers.

By integrating the Vibration Isolator 4324255 into the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, Cummins ensures that these engines operate with enhanced stability and reduced mechanical stress, contributing to their reliability and efficiency.

Role of Part 4324255 Vibration Isolator in Engine Systems

The Part 4324255 Vibration Isolator is instrumental in maintaining the operational integrity of various engine systems by effectively mitigating vibrations that can arise during engine operation.

Integration with the Primer System

When integrated with the primer system, the Vibration Isolator ensures that the primer operates smoothly without being adversely affected by engine vibrations. This stability is essential for the primer to deliver a consistent fuel supply to the engine, especially during startup. The isolator absorbs and dampens vibrations, allowing the primer to function optimally and ensuring reliable engine ignition.

Interaction with the Engine Lubricating System

In the context of the engine lubricating system, the Vibration Isolator plays a significant role in preserving the efficiency of lubrication. Engine vibrations can disrupt the flow of lubricant, leading to inconsistent oil distribution and potential wear on moving parts. By isolating these vibrations, the isolator helps maintain a steady lubricant flow, ensuring that all engine components receive adequate lubrication. This results in reduced friction, lower wear rates, and enhanced overall engine performance.

The isolator’s ability to stabilize the lubricating system contributes to the longevity and reliability of the engine, making it a valuable component in the maintenance of engine health.

Conclusion

The Cummins 4324255 Vibration Isolator is a critical component in the operation of commercial trucks and heavy-duty engines. By effectively mitigating vibrations, it enhances the stability, comfort, and longevity of the vehicle and its components. Proper installation, regular maintenance, and timely replacement are essential for ensuring the optimal performance of this part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, Robert Bosch GmbH, 2014.

↩ -

Modern Diesel Technology: Light Duty Diesels, Sean Bennett, Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.