This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

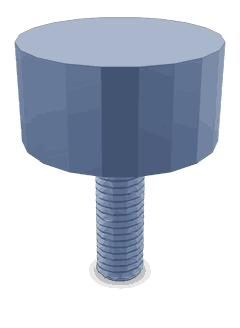

The Cummins 4324256 Vibration Isolator is engineered to reduce the transmission of vibrations from the engine or drivetrain to the truck’s frame and cabin. This is vital for preserving equipment integrity, enhancing performance, and ensuring driver and passenger comfort in commercial truck operations.

Basic Concepts of Vibration Isolators

Vibration isolators are designed to minimize the transmission of vibrations between mechanical systems by absorbing or dampening vibrational energy. This prevents the spread of vibrations to other parts of the system, which is essential for maintaining the integrity and performance of mechanical equipment. Excessive vibrations can lead to wear, fatigue, and potential failure of components 1.

Purpose of the 4324256 Vibration Isolator

The Cummins 4324256 Vibration Isolator reduces vibrations transmitted from the engine or drivetrain to the truck’s frame and cabin. This contributes to a smoother vehicle operation, reducing the impact of vibrations on both mechanical components and occupant comfort.

Key Features

The Cummins 4324256 Vibration Isolator is designed with materials resilient to vibrational stresses, ensuring long-term reliability. It is engineered to fit seamlessly within the truck’s existing structure, requiring minimal modifications for installation. The isolator is built to withstand harsh conditions, including varying temperatures and mechanical stresses 2.

Benefits

Using the Cummins 4324256 Vibration Isolator improves ride comfort by minimizing vibrations transmitted to the cabin. It also reduces wear and tear on truck components, potentially extending their lifespan. Furthermore, it enhances overall comfort for the driver and passengers.

Installation Considerations

Proper installation of the Cummins 4324256 Vibration Isolator is crucial for optimal performance. Preparatory steps include inspecting the installation area for damage or irregularities. Using appropriate tools ensures a secure and precise installation. Alignment considerations are vital to ensure the isolator effectively isolates vibrations.

Troubleshooting Common Issues

Common issues with vibration isolators include signs of wear or failure, such as cracks, deformation, or increased transmitted vibrations. Troubleshooting involves inspecting the isolator for physical damage, checking alignment and fit, and assessing the condition of surrounding components. If significant wear or failure is detected, replacement may be necessary to maintain effective vibration isolation.

Maintenance Tips

Regular maintenance of the Cummins 4324256 Vibration Isolator is recommended to prolong its lifespan and ensure consistent performance. This includes routine inspections for wear, damage, or misalignment, cleaning procedures to remove debris or contaminants, and making necessary adjustments to ensure secure and correct installation.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its extensive product range, designed to meet the demanding requirements of commercial vehicle operations 3.

Cummins Vibration Isolator 4324256 Compatibility

The Cummins Vibration Isolator part number 4324256 is compatible with QSK95 engines, specifically the models CM2350 K111 and CM2350 K113. This part is engineered to mitigate vibrations and noise during engine operation, ensuring smoother and more efficient performance.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, installing the 4324256 Vibration Isolator is straightforward and crucial for maintaining the integrity of the engine’s components. By absorbing and dampening vibrations, this isolator helps prolong the engine’s lifespan and reduce wear on connected parts.

The compatibility of the 4324256 Vibration Isolator with these specific QSK95 engine models ensures consistent and reliable performance across the engine fleet. This part is a critical component in the maintenance and operational efficiency of these engines.

Role of Part 4324256 Vibration Isolator in Engine Systems

The Part 4324256 Vibration Isolator is crucial in mitigating the transmission of vibrations within engine systems. When integrated with various engine components, it significantly enhances overall performance and longevity.

Integration with Accessories

In engine systems, accessories such as alternators, air conditioning compressors, and power steering pumps generate vibrations during operation. The Vibration Isolator, when fitted between these accessories and the engine block, effectively dampens these vibrations. This reduction in vibrational energy prevents undue stress on the accessory mounts and the engine itself, leading to smoother operation and reduced wear.

Fuel System Stability

The fuel system, comprising the fuel pump, fuel lines, and fuel filter, is sensitive to vibrations. Excessive vibrations can lead to fuel line fatigue, leaks, and inefficient fuel delivery. By installing the Vibration Isolator at key points within the fuel system, such as between the fuel pump and the engine or along the fuel lines, the isolator ensures that the fuel system components operate in a stable environment. This stability enhances fuel efficiency and reliability.

Filter and Fuel Filter Head Protection

Filters, including the fuel filter and oil filter, are critical for maintaining the cleanliness of fluids within the engine. Vibrations can cause these filters to become dislodged or damaged, leading to contamination of the engine oil or fuel. The Vibration Isolator, when used in conjunction with filter mounts, provides a secure and stable platform for these components. This ensures that the filters remain firmly in place and function optimally, thereby protecting the engine from harmful contaminants.

Overall Engine Performance

By addressing vibrations across these components—accessories, fuel system, filters, and fuel filter head—the Part 4324256 Vibration Isolator plays a significant role in maintaining the integrity and performance of the engine system. It contributes to a quieter, more efficient, and longer-lasting engine by ensuring that each component operates within its designed parameters, free from the detrimental effects of excessive vibration.

Conclusion

The Cummins 4324256 Vibration Isolator is a vital component in commercial truck operations, designed to reduce vibrations transmitted from the engine or drivetrain to the truck’s frame and cabin. Its key features, benefits, and compatibility with specific engine models make it an essential part for maintaining equipment integrity, enhancing performance, and ensuring driver and passenger comfort. Regular maintenance and proper installation are crucial for optimal performance and longevity of this part.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.