4382392

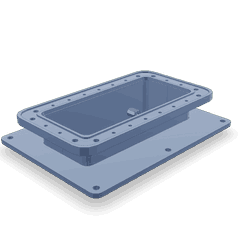

Thermal Isolator

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4382392 Thermal Isolator is a component designed to manage heat within the mechanical systems of commercial trucks. Its purpose is to regulate temperature by minimizing heat transfer between different parts of the engine or exhaust system. This regulation is significant for maintaining optimal operating conditions and ensuring the longevity and efficiency of the truck’s engine 1.

Basic Concepts of Thermal Isolators

Thermal isolators are devices used in mechanical systems to prevent or reduce the transfer of heat between components. They function by creating a barrier that inhibits heat flow, thus maintaining desired temperature levels in various parts of the system. In the context of trucks, thermal isolators play a role in protecting sensitive components from excessive heat, which can lead to performance issues or damage 2.

Purpose of the Cummins 4382392 Thermal Isolator

The Cummins 4382392 Thermal Isolator is specifically designed to be installed in the engine or exhaust system of a truck. Its role is to reduce the amount of heat transferred from the exhaust system to the engine block or other nearby components. By doing so, it helps maintain a stable operating temperature, which contributes to the overall efficiency and reliability of the engine 3.

Key Features

This Cummins part is characterized by its robust design and the materials used in its construction. It is made from high-quality, heat-resistant materials that ensure durability and effective thermal management. The isolator’s design includes features that enhance its performance, such as precise fitting to ensure a secure installation and optimal heat barrier functionality.

Benefits of Using the Cummins 4382392 Thermal Isolator

Utilizing the Cummins 4382392 Thermal Isolator offers several advantages. It contributes to improved engine efficiency by helping to maintain optimal operating temperatures. Additionally, it reduces the heat transfer to adjacent components, which can prevent overheating and potential damage. The isolator also enhances the durability of the engine system by protecting components from excessive heat.

Installation Considerations

Proper installation of the Cummins 4382392 Thermal Isolator is important for its effective functioning. It is recommended to follow manufacturer guidelines for installation, which may include specific prerequisites or the use of special tools. Ensuring a correct fit and secure placement is crucial for the isolator to perform its intended role in thermal management.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4382392 Thermal Isolator involves inspection for signs of wear or failure. It is important to check for any damage or deterioration that could compromise its effectiveness. Troubleshooting common issues may involve assessing the fit and condition of the isolator, as well as ensuring that it is functioning as intended within the engine or exhaust system.

Role of the 4382392 Thermal Isolator in Engine Systems

The integration of the 4382392 Thermal Isolator within engine systems is essential for maintaining optimal performance and efficiency of various components. This component is strategically positioned to manage heat transfer between the Aftertreatment Device and the Decomposition Reactor.

Interaction with Aftertreatment Device

In the context of the Aftertreatment Device, the Thermal Isolator ensures that the heat generated during the exhaust gas treatment process is effectively contained. This containment prevents undue thermal stress on adjacent components, thereby prolonging the service life of the Aftertreatment Device. It also aids in maintaining the precise temperature conditions required for the efficient operation of the device, which is vital for reducing emissions and meeting regulatory standards.

Function within the Decomposition Reactor

When considering the Decomposition Reactor, the Thermal Isolator plays a significant role in regulating the temperature environment. The reactor relies on specific thermal conditions to facilitate the breakdown of harmful substances in the exhaust gases. The isolator helps in maintaining these conditions by preventing heat loss, thus ensuring that the reactor operates within its designed temperature range. This results in enhanced decomposition efficiency and contributes to the overall effectiveness of the aftertreatment system.

Contribution to the Service Kit

In a Service Kit, the inclusion of the Thermal Isolator is indicative of its importance in preserving the integrity and functionality of the aftertreatment system components. Regular replacement or inspection of the isolator as part of routine maintenance can prevent thermal-related failures and ensure consistent performance of the engine system.

Overall System Integration

The Thermal Isolator’s role extends beyond individual components; it is a key element in the holistic management of thermal dynamics within the engine system. By effectively isolating heat, it contributes to the stability and reliability of the entire aftertreatment process, from the initial treatment of exhaust gases to their final decomposition. This integration is fundamental in achieving the desired emission reduction goals and ensuring the longevity of the engine’s aftertreatment components.

Conclusion

The Cummins 4382392 Thermal Isolator is a vital component in the thermal management of commercial truck engines. Its role in regulating heat transfer, protecting sensitive components, and contributing to the overall efficiency and reliability of the engine system underscores its importance in modern automotive engineering.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.