This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4931781 Vibration Isolator is designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. It plays a role in maintaining the operational efficiency and comfort of commercial trucks by reducing the impact of engine vibrations.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from one part of a system to another. They function by absorbing or dampening vibrations, thereby minimizing their impact on connected components. In the context of trucks and other heavy machinery, vibration isolators enhance ride comfort, protect sensitive components from excessive vibrations, and contribute to the overall durability of the vehicle 1.

Purpose of the 4931781 Vibration Isolator

The Cummins 4931781 Vibration Isolator is designed to reduce the transmission of engine vibrations to the truck’s frame and other components. This reduction in vibration contributes to a smoother ride, less wear on connected parts, and improved overall performance of the truck.

Key Features

The Cummins 4931781 Vibration Isolator features a design that incorporates high-quality materials to ensure durability and effectiveness. Its construction includes elastomeric components that provide the necessary flexibility and resilience to absorb vibrations. Additionally, the isolator is engineered to withstand the harsh conditions typical of commercial truck operations, ensuring long-term reliability.

Benefits of Using the 4931781 Vibration Isolator

Utilizing the Cummins 4931781 Vibration Isolator offers several advantages. It contributes to improved ride comfort by reducing the transmission of engine vibrations to the truck’s cabin. Furthermore, it plays a role in reducing wear on components connected to the engine, thereby enhancing the longevity of these parts. The isolator also contributes to the overall durability of the truck by minimizing the impact of vibrations on its structure.

Installation and Integration

Proper installation of the Cummins 4931781 Vibration Isolator is crucial for its effective operation. It should be integrated into the truck’s system according to the manufacturer’s guidelines, ensuring that all connections are secure and that the isolator is correctly positioned to absorb vibrations effectively. Consideration should be given to the alignment and spacing to ensure optimal performance.

Troubleshooting Common Issues

Common issues associated with vibration isolators may include reduced effectiveness over time due to wear or damage. Troubleshooting steps may involve inspecting the isolator for signs of wear, ensuring that it is correctly installed, and replacing it if necessary to maintain its vibration-dampening capabilities.

Maintenance Tips

Regular maintenance of the Cummins 4931781 Vibration Isolator is recommended to ensure its continued effectiveness. This may include periodic inspections for signs of wear or damage, ensuring that all connections remain secure, and replacing the isolator if it shows signs of significant wear. Adhering to these maintenance practices contributes to the isolator’s longevity and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial truck operators worldwide 2.

Compatibility

The Cummins Vibration Isolator part number 4931781 is designed to fit seamlessly with several engine models, providing essential vibration dampening and noise reduction. This part is crucial for maintaining the operational integrity and longevity of the engines it supports.

Compatible Engines

- 4B3.9 and 6B5.9 Engines

The 4931781 Vibration Isolator is compatible with both the 4B3.9 and 6B5.9 engines. These engines, known for their robust performance and reliability, benefit significantly from the vibration dampening properties of this isolator. By reducing the transmission of vibrations from the engine to the vehicle’s chassis, it enhances the overall driving experience and protects engine components from undue wear and tear.

- B5.9 GAS PLUS CM556 Engine

The B5.9 GAS PLUS CM556 engine also integrates well with the 4931781 Vibration Isolator. This engine model, which is part of Cummins’ lineup of high-performance gas engines, relies on this isolator to maintain smooth operation. The isolator’s ability to mitigate vibrations helps in preserving the precision and efficiency of the engine’s components, ensuring optimal performance under various operating conditions.

Grouping and Application

The 4931781 Vibration Isolator is a versatile component that can be applied across different engine types within the Cummins portfolio. Its design and functionality make it an ideal choice for:

- Medium-Duty and Heavy-Duty Applications

The isolator is particularly suited for medium-duty and heavy-duty applications where engine vibrations can be more pronounced. By effectively isolating these vibrations, the isolator contributes to the overall stability and comfort of the vehicle.

- Industrial and Commercial Use

In industrial and commercial settings, where engines are often subjected to rigorous use, the 4931781 Vibration Isolator plays a critical role in maintaining engine health and operational efficiency. Its application in these environments helps in reducing maintenance costs and extending the lifespan of the engines.

Role of the 4931781 Vibration Isolator in Engine Systems

The 4931781 Vibration Isolator is an essential component in mitigating the transmission of vibrations from the engine to other parts of the vehicle. Its application within various engine systems is designed to enhance the overall performance and longevity of the engine and its associated components.

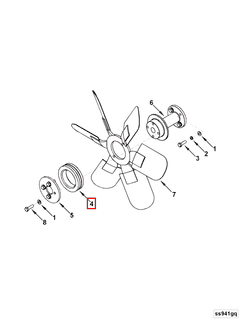

Integration with Adapter and Front Drive

When integrated with the adapter and front drive components, the Vibration Isolator effectively reduces the vibrational forces that can be transmitted through these parts. This reduction in vibration helps maintain the structural integrity of the adapter and front drive, ensuring smoother operation and reducing wear and tear.

Functionality in Engine Installation

During engine installation, the Vibration Isolator plays a significant role in stabilizing the engine mount. By absorbing and dampening vibrations, it ensures that the engine remains securely in place without excessive movement. This stability is vital for the precise alignment of the engine with other components, contributing to efficient engine performance.

Interaction with Spacer and Fan Pilot

The Vibration Isolator also interacts with the spacer and fan pilot to enhance the overall vibrational management of the engine system. The spacer, often used to maintain proper distances between components, benefits from the reduced vibrations, which can otherwise lead to misalignment or damage. Similarly, the fan pilot, which controls the operation of the engine fan, operates more efficiently with minimized vibrational interference, leading to better cooling performance and reduced mechanical stress.

Conclusion

The Cummins 4931781 Vibration Isolator is a critical component for the 4B3.9, 6B5.9, and B5.9 GAS PLUS CM556 engines. Its compatibility with these engines ensures effective vibration dampening, contributing to smoother operation, reduced wear, and enhanced durability. This part is indispensable for maintaining the performance and reliability of Cummins engines in various applications.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.