This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

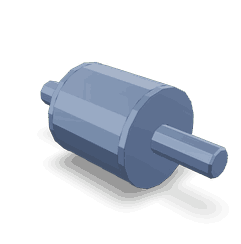

The Cummins 4931811 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine or drivetrain to the truck’s frame and cabin. In the context of heavy-duty truck operations, this part plays a significant role in enhancing the overall performance and comfort of the vehicle.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used to reduce the transmission of vibrations between two surfaces. They function by absorbing or dampening the vibrational energy, thus preventing it from being transferred. In mechanical systems, vibration isolators are crucial for maintaining equipment integrity and performance 1. They operate on the principle of isolating the source of vibration from the rest of the system, thereby protecting sensitive components and improving operational efficiency.

Purpose of the 4931811 Vibration Isolator

The Cummins 4931811 Vibration Isolator is specifically designed to reduce vibrations transmitted from the engine or drivetrain to the truck’s frame and cabin. By doing so, it helps in maintaining a stable and comfortable environment for both the driver and passengers, while also protecting the truck’s structural components from excessive wear and tear.

Key Features

The Cummins 4931811 Vibration Isolator boasts several key features that enhance its performance and durability. These include a robust material composition designed to withstand the rigors of heavy-duty truck operations, a design that ensures effective vibration dampening, and unique characteristics that contribute to its longevity and reliability.

Benefits of Using the 4931811 Vibration Isolator

Incorporating the Cummins 4931811 Vibration Isolator into truck designs offers several advantages. These include improved ride comfort for both the driver and passengers, reduced wear and tear on truck components due to minimized vibrations, and an overall enhanced driving experience. The isolator contributes to the longevity of the truck’s structural components by mitigating the effects of vibrational stress.

Installation and Integration

Proper installation of the Cummins 4931811 Vibration Isolator is vital for its effective functioning. Guidelines and considerations for installation include ensuring compatibility with various truck models, correct mounting, and precise alignment. Attention to these details during installation helps in maximizing the isolator’s performance and ensuring its longevity.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 4931811 Vibration Isolator include wear and tear, misalignment, or failure to dampen vibrations effectively. Troubleshooting steps may involve inspecting the isolator for signs of damage, ensuring proper alignment, and replacing worn-out components. Regular maintenance, such as checking for signs of wear and ensuring tight mounting, can help in maintaining the isolator’s performance and longevity.

Performance and Testing

The performance of the Cummins 4931811 Vibration Isolator is measured through rigorous testing procedures. These tests evaluate its effectiveness in dampening vibrations, durability under heavy-duty conditions, and overall reliability. The isolator undergoes various tests to ensure it meets the high standards set by Cummins Corporation for quality and performance.

Cummins Corporation

Cummins Corporation, a leader in the automotive and heavy-duty truck industry, is known for its commitment to innovation, quality, and customer satisfaction. With a rich history of providing reliable and high-performance components, Cummins continues to play a significant role in advancing the technology and efficiency of heavy-duty trucks. The company’s dedication to excellence is reflected in its products, including the Cummins 4931811 Vibration Isolator.

Cummins Vibration Isolator 4931811 in Engine Applications

The Cummins Vibration Isolator part number 4931811 is a critical component designed to mitigate the impact of engine vibrations in various engine models. This part is engineered to enhance the operational efficiency and longevity of the engines by reducing the transmission of harmful vibrations to the engine mounts and other structural components.

Application in Specific Engine Models

- 6B5.9 Engine Series

The 6B5.9 engine series benefits significantly from the integration of the Cummins Vibration Isolator 4931811. This engine model, known for its robust performance, can experience considerable vibrations during operation. The vibration isolator helps to dampen these vibrations, ensuring smoother operation and reducing wear on engine mounts and other related parts. By effectively isolating the engine from the chassis, it contributes to a more stable and reliable performance, which is crucial for the longevity and efficiency of the engine.

Grouping of Engine Models

In the broader context, the Cummins Vibration Isolator 4931811 is applicable across various engine models that share similar design and operational characteristics. This part is particularly beneficial in high-performance engines where vibration control is paramount. By grouping engines based on their need for vibration reduction, the isolator ensures that engines operate within optimal parameters, enhancing overall performance and durability.

Role of Part 4931811 Vibration Isolator in Engine Systems

In the intricate assembly of engine systems, the 4931811 Vibration Isolator serves a significant function by mitigating the transmission of vibrations between various components. This is particularly important in ensuring the smooth operation and longevity of the engine.

Integration with Air Intake System

When integrated with the Air Intake (AI) system, the Vibration Isolator helps in stabilizing the intake manifold and associated ductwork. By reducing the vibrational energy transmitted from the engine to the intake system, it ensures that the airflow remains consistent and undisturbed. This stability is essential for maintaining optimal air-fuel mixture ratios, which directly influence engine performance and efficiency.

Application in Air Heater Starting System

In the Air Heater Starting (AHS) system, the Vibration Isolator is employed to secure the air heater and its connections to the engine. The AHS system relies on precise and consistent airflow to preheat the intake air, especially in cold-start conditions. The isolator’s role here is to prevent vibrations from affecting the heater’s performance, ensuring that it operates efficiently without disruptions.

Connection to Auxiliary Systems

The Vibration Isolator also plays a part in stabilizing connections to auxiliary systems such as the Aid system. These systems often include components like sensors and control units that are sensitive to vibrations. By isolating these components from engine vibrations, the isolator helps in maintaining the accuracy and reliability of the data these systems provide, which is vital for engine management and diagnostics.

Overall Engine Stability

Beyond specific systems, the 4931811 Vibration Isolator contributes to the overall stability of the engine assembly. By reducing the vibrational impact on mounting points and structural components, it helps in preventing wear and tear, thereby extending the service life of the engine and its components. This is particularly beneficial in high-performance engines where vibrations can be more pronounced.

Conclusion

The Cummins 4931811 Vibration Isolator is an essential component in maintaining the operational integrity and efficiency of various engine systems. Its application across different components underscores its versatility and importance in engine design and performance. By effectively dampening vibrations, this part ensures smoother operation, reduces wear on critical components, and contributes to the overall stability and longevity of the engine.

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.