This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

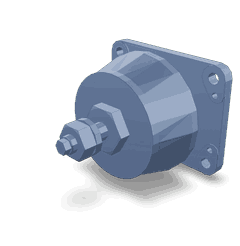

The 4932440 Vibration Isolator, a component manufactured by Cummins, is designed specifically for use in commercial trucks. This part is integral to the operation of heavy-duty vehicles, where the management of vibrations is paramount. Vibration isolators serve to mitigate the transmission of vibrations from the engine and drivetrain to the truck’s frame and cabin. This not only enhances ride comfort but also contributes to the longevity of the vehicle by reducing wear and tear on various components.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between two surfaces. They function by absorbing and dissipating vibrational energy, thereby minimizing its impact on connected parts. The principle of vibration isolation involves the use of materials that can absorb and dampen vibrations, typically elastomers or other flexible materials. These materials are chosen for their ability to flex and return to their original shape, effectively isolating vibrations 1.

Purpose of the 4932440 Vibration Isolator

The 4932440 Vibration Isolator plays a specific role in the operation of a truck by reducing the transmission of engine and drivetrain vibrations to the truck’s frame. This reduction in vibration contributes to the overall performance and durability of the vehicle. By isolating vibrations, the isolator helps maintain the integrity of the truck’s components, ensuring they operate within their designed parameters for a longer period 2.

Key Features

The 4932440 Vibration Isolator is characterized by several key features that distinguish it from other vibration isolators. Its design incorporates materials that offer superior vibration absorption capabilities. Additionally, the isolator is engineered to withstand the harsh conditions typical of commercial truck operations, including exposure to extreme temperatures and heavy loads. Its unique characteristics ensure effective vibration isolation under a wide range of operating conditions 3.

Benefits of Using the 4932440 Vibration Isolator

Incorporating the 4932440 Vibration Isolator into truck designs offers several advantages. It contributes to improved ride comfort by reducing the vibrations felt by the driver and passengers. Furthermore, by minimizing the transmission of vibrations to the truck’s frame and components, it helps reduce wear and tear, potentially extending the vehicle’s lifespan. The isolator also plays a role in maintaining the overall performance and reliability of the truck 4.

Installation Considerations

Proper installation of the 4932440 Vibration Isolator is crucial for its effective performance. Guidelines recommend ensuring proper alignment and secure attachment to the truck’s frame and engine components. This ensures that the isolator can perform its function optimally, providing the intended benefits of vibration isolation.

Troubleshooting Common Issues

Common issues associated with vibration isolators may include excessive vibration or noise, which can indicate a problem with the isolator’s performance. Troubleshooting steps may involve inspecting the isolator for signs of wear or damage, ensuring it is properly installed, and checking for any loose connections. Addressing these issues promptly can help maintain the effectiveness of the vibration isolation system.

Maintenance Tips

Regular maintenance of the 4932440 Vibration Isolator is recommended to ensure its continued effective performance. This may include periodic inspections for signs of wear or damage, cleaning the isolator to remove any debris that could affect its performance, and replacing the isolator if it shows significant signs of wear or if its performance diminishes.

Cummins: A Brief Overview

Cummins is a well-established manufacturer in the commercial truck industry, known for its wide range of high-quality components. The company’s history of innovation and commitment to quality has earned it a reputation as a trusted name for truck components. Cummins’ product range includes engines, transmissions, and various other parts designed to enhance the performance, efficiency, and reliability of commercial trucks.

Cummins Vibration Isolator 4932440 Compatibility with K38 and K50 Engines

The Cummins Vibration Isolator part number 4932440 is a critical component designed to mitigate the effects of engine vibrations, ensuring smoother operation and reducing wear on engine components. This part is engineered to fit seamlessly within the engine architecture of both the K38 and K50 engines, providing a reliable solution for vibration management.

In the K38 engine series, the 4932440 Vibration Isolator is specifically tailored to address the unique vibration characteristics of this engine model. Its design allows it to absorb and dampen the vibrations generated during engine operation, contributing to the longevity and efficiency of the engine.

Similarly, for the K50 engine series, the 4932440 Vibration Isolator is engineered to fit perfectly within the engine’s framework. This ensures that the engine operates with minimal vibration, which is crucial for maintaining performance and reducing maintenance needs.

Both the K38 and K50 engines benefit from the use of the 4932440 Vibration Isolator, as it provides a consistent and reliable method for managing engine vibrations. This compatibility highlights the versatility and effectiveness of the Cummins Vibration Isolator in enhancing engine performance across different engine models.

Role of Part 4932440 Vibration Isolator in Engine Systems

The part 4932440 Vibration Isolator is instrumental in mitigating the transmission of vibrations from the engine to other components, ensuring smoother operation and enhanced durability of the engine system.

Interaction with the Rail

When integrated with the rail, the Vibration Isolator effectively dampens the vibrations generated by the engine’s operation. This is particularly important in high-performance engines where the forces and vibrations are more pronounced. By reducing these vibrations, the isolator helps maintain the structural integrity of the rail, preventing premature wear and potential failure. Additionally, it contributes to a more stable and consistent performance of the engine, as the rail can maintain its alignment and support functions without undue stress from vibrational forces.

Integration with the Base

The base of the engine system also benefits significantly from the incorporation of the Vibration Isolator. The base must withstand substantial loads and vibrations, especially in applications where the engine is subjected to varying operational conditions. The isolator absorbs and dissipates a significant portion of these vibrations, thereby protecting the base from fatigue and stress-related damage. This not only prolongs the lifespan of the base but also ensures that the engine remains securely mounted, which is essential for safe and efficient operation.

Conclusion

In summary, the 4932440 Vibration Isolator plays a key role in enhancing the performance and longevity of both the rail and the base within engine systems by effectively managing vibrational energy. Its integration into the engine system ensures smoother operation, reduces wear and tear on critical components, and contributes to the overall reliability and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.