This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

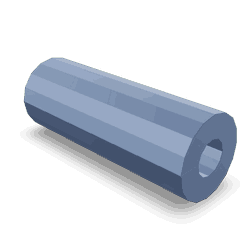

The Cummins 4945989 Noise Isolator is a critical component designed to mitigate unwanted noise in commercial trucks. Its primary application is within the engine compartment, where it significantly contributes to maintaining a quieter operational environment. This isolator is part of Cummins’ broader initiative to enhance the operational efficiency and comfort of commercial vehicles 1.

Basic Concepts of Noise Isolators

A noise isolator is a device that reduces the transmission of sound or vibration from one part of a mechanical system to another. It functions by absorbing, reflecting, or otherwise impeding the passage of sound waves. In commercial trucks, noise isolators are essential for minimizing the noise produced by the engine and other mechanical components, contributing to a more comfortable driving experience and potentially reducing wear on the vehicle’s components 2.

Role of the 4945989 Noise Isolator in Truck Operation

The Cummins 4945989 Noise Isolator integrates with the truck’s engine to reduce the noise generated during operation. It is strategically positioned to absorb or dampen the vibrations and sounds produced by the engine, thereby reducing the overall noise level within the truck’s cabin and its surroundings. This integration helps create a more pleasant environment for the driver and passengers and may also contribute to the longevity of the vehicle by reducing the stress on components caused by excessive vibration 3.

Key Features

The Cummins 4945989 Noise Isolator is characterized by its robust design and the materials used in its construction. It is made from high-quality, durable materials that can withstand the harsh conditions within a truck’s engine compartment. Its design is tailored to effectively absorb and dissipate noise and vibrations, ensuring it performs efficiently under various operating conditions. Additionally, the isolator is engineered to be easy to install, ensuring it can be quickly integrated into the truck’s engine system with minimal disruption.

Benefits of Using the 4945989 Noise Isolator

The use of the Cummins 4945989 Noise Isolator offers several advantages. Primarily, it significantly reduces the noise emitted by the truck’s engine, contributing to a quieter operational environment. This not only enhances driver comfort but can also improve communication within the cabin. Furthermore, by reducing engine noise, the isolator may help in minimizing the stress on the vehicle’s components, potentially leading to improved durability and longevity of the truck.

Troubleshooting and Maintenance

Common issues with the Cummins 4945989 Noise Isolator may include reduced effectiveness over time due to wear and tear or damage from extreme conditions. Regular inspection and maintenance are recommended to ensure optimal performance. This includes checking for signs of wear, ensuring it remains securely attached, and replacing it if significant damage is observed. Proper maintenance practices can help in prolonging the life of the isolator and ensuring it continues to effectively reduce engine noise.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the industry, known for its commitment to innovation, quality, and customer satisfaction. Its expertise in engine and component manufacturing is evident in the design and performance of products like the Cummins 4945989 Noise Isolator, reflecting the company’s dedication to enhancing the efficiency and comfort of commercial vehicles.

Compatibility of Noise Isolator Part 4945989 with Cummins Engines

The Cummins Noise Isolator part 4945989 is designed to fit a range of Cummins engines, providing effective noise reduction and enhancing the operational environment for the machinery. This part is engineered to be compatible with several models, ensuring that it can be utilized across different applications.

Compatible Engines

- ISB (Chrysler)

- ISC CM850

- ISL9 CM2150 SN

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

Grouped Compatibility

The Noise Isolator part 4945989 is particularly suited for the following groups of engines:

-

ISC Series: This includes the ISC CM850 and QSL9 CM850 (CM2850). These engines benefit from the noise reduction capabilities of the isolator, ensuring quieter operation and improved working conditions.

-

ISL Series: The ISL9 CM2150 SN and QSL8.9 CM2150 L141 engines are part of this series. The noise isolator is designed to fit seamlessly with these models, providing the necessary acoustic dampening.

-

QSC Series: The QSC8.3 CM850 (CM2850) engine is also compatible with the part 4945989. This compatibility ensures that the noise levels are kept to a minimum, which is crucial for environments where noise pollution can be a concern.

By fitting the Noise Isolator part 4945989 to these engines, users can expect a reduction in operational noise, leading to a more comfortable and productive working environment.

Role of Part 4945989 Noise Isolator in Engine Systems

The integration of part 4945989 Noise Isolator within engine systems is designed to enhance performance and reduce unwanted noise. This component is strategically positioned to interact with several key engine parts, ensuring optimal operation and efficiency.

Interaction with the Camshaft

The Noise Isolator works in conjunction with the camshaft to mitigate vibrations and noise generated during the valve operation. By dampening these vibrations, it contributes to a smoother engine operation, which is essential for maintaining the longevity and performance of the camshaft.

Connecting Rod and Piston Assembly

When installed, the Noise Isolator interfaces with the connecting rod and piston assembly. It helps in reducing the noise produced by the reciprocating motion of the pistons. This reduction in noise not only improves the auditory experience but also indicates a decrease in mechanical stress on the components.

Cylinder Head Integration

The Noise Isolator is also effective in its interaction with the cylinder head. It reduces the transmission of noise and vibrations from the combustion process, which can otherwise lead to increased wear on the cylinder head and adjacent components.

Fuel Manifold and Injector Fuel Supply Tube

In the fuel system, the Noise Isolator is positioned to interact with the fuel manifold and injector fuel supply tube. It helps in minimizing the noise associated with fuel delivery, ensuring a quieter operation of the fuel system. This is particularly important in high-performance engines where fuel delivery precision is paramount.

Injector Plumbing

The Noise Isolator also plays a role in the injector plumbing system. By reducing the noise from the high-pressure fuel lines, it ensures that the injectors operate in a quieter environment. This can lead to improved fuel atomization and combustion efficiency.

Overall Engine Performance

In summary, part 4945989 Noise Isolator is a component that, while small in size, has a significant impact on the overall performance and noise reduction of engine systems. Its effective integration with various engine components ensures a smoother, more efficient, and quieter engine operation.

Conclusion

The Cummins 4945989 Noise Isolator is a vital component in the quest for quieter, more efficient commercial truck operations. Its robust design, compatibility with a range of Cummins engines, and the significant benefits it offers in terms of noise reduction and engine longevity make it an indispensable part of modern truck engine systems. Regular maintenance and proper installation are key to ensuring its optimal performance, contributing to a more comfortable and productive driving experience.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.