This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4946720 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. In the context of heavy-duty truck operations, this part plays a significant role in ensuring the smooth and efficient functioning of the vehicle. By reducing vibrations, it contributes to the overall performance, durability, and comfort of the truck 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used to reduce the transmission of vibrations from a vibrating source to its surroundings. They function by absorbing, reflecting, or otherwise altering the vibrational energy, thereby minimizing its impact on connected structures. In mechanical systems, vibration isolators are crucial for maintaining equipment integrity and performance, as excessive vibrations can lead to wear, fatigue, and potential failure of components 2.

Purpose of the 4946720 Vibration Isolator

The Cummins 4946720 Vibration Isolator is specifically designed to reduce vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, enhancing ride comfort for the driver and passengers, and ensuring the longevity of various truck components.

Key Features

The Cummins 4946720 Vibration Isolator boasts several key features that enhance its performance and durability. These include a robust material composition designed to withstand the rigors of heavy-duty truck operations, a design that optimizes vibration absorption, and unique characteristics that ensure consistent performance under varying conditions.

Benefits of Using the 4946720 Vibration Isolator

Incorporating the Cummins 4946720 Vibration Isolator into truck designs offers several advantages. These include improved ride comfort due to reduced vibrations, decreased wear and tear on truck components leading to longer lifespan, and enhanced engine performance by ensuring a stable mounting environment.

Installation Considerations

Proper installation of the Cummins 4946720 Vibration Isolator is vital for its optimal performance. Guidelines and best practices include ensuring proper alignment with the engine and frame, adhering to specified torque values during installation, and performing any necessary preparatory steps to facilitate a secure and effective fit.

Troubleshooting Common Issues

Common problems associated with vibration isolators may include symptoms of failure such as increased vibrations, unusual noises, or visible damage to the isolator. Diagnostic procedures involve inspecting the isolator for signs of wear, checking alignment and mounting, and assessing the overall condition of the isolator. Potential solutions may range from re-alignment or tightening to replacement of the isolator.

Maintenance Tips

Regular maintenance of the Cummins 4946720 Vibration Isolator is recommended to ensure its longevity and consistent performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may affect performance, and considering replacement based on the manufacturer’s guidelines or when signs of significant wear are observed.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a rich history of innovation and a commitment to excellence, Cummins serves the automotive and heavy-duty truck industries with a diverse product range designed to meet the demanding requirements of modern transportation.

Cummins Vibration Isolator 4946720 Compatibility

The Cummins Vibration Isolator part number 4946720 is designed to be compatible with a range of Cummins engines, ensuring effective noise and vibration reduction. This part is engineered to fit seamlessly within the engine’s mounting system, providing a stable and reliable connection between the engine and the vehicle chassis.

QSB3.3 CM2150

The QSB3.3 CM2150 engine is one of the models that can utilize the 4946720 Vibration Isolator. This engine is known for its robust performance and reliability, making it a popular choice for various applications. The Vibration Isolator ensures that the engine’s vibrations are minimized, contributing to a smoother and quieter operation.

Group Compatibility

The 4946720 Vibration Isolator is part of a broader range of vibration isolators designed by Cummins. These parts are engineered to fit various engine models, ensuring that the engine’s vibrations are effectively managed across different applications. The compatibility of this part with the QSB3.3 CM2150 engine highlights its versatility and effectiveness in reducing engine noise and vibration.

Role of Part 4946720 Vibration Isolator in Engine Systems

The 4946720 Vibration Isolator is an essential component in ensuring the smooth operation of engine systems by mitigating unwanted vibrations. When integrated with the Harness and Electronic Control Module (ECM) Wiring, this part significantly enhances the performance and longevity of the engine.

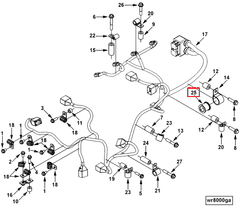

Integration with Harness

The Harness serves as the primary conduit for electrical signals and power within the engine system. By incorporating the 4946720 Vibration Isolator, the harness benefits from reduced mechanical stress. This reduction in stress helps maintain the integrity of the electrical connections, ensuring consistent signal transmission and power delivery. As a result, the engine’s electronic systems operate more reliably, leading to improved overall performance.

Interaction with ECM Wiring

The ECM Wiring is responsible for connecting the Electronic Control Module to various sensors and actuators throughout the engine. The 4946720 Vibration Isolator plays a supportive role by isolating vibrations that could otherwise interfere with the delicate electronic components. This isolation helps prevent signal disruptions and ensures that the ECM receives accurate data from sensors. Consequently, the ECM can make precise adjustments to the engine’s operation, enhancing fuel efficiency and reducing emissions.

Conclusion

In summary, the 4946720 Vibration Isolator works in tandem with the harness and ECM wiring to create a more stable and efficient engine environment. Its role in vibration management is key to maintaining the reliability and performance of these critical engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.