This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5410318 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. Its role is significant in the operation of commercial trucks, contributing to the overall efficiency, comfort, and longevity of the vehicle.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used to reduce the transmission of vibrations between mechanical systems. They function by absorbing or dampening the vibrations produced by machinery, thereby preventing these vibrations from affecting other parts of the system. In the context of heavy-duty trucks, vibration isolators play a role in maintaining the structural integrity of the vehicle, enhancing driver and passenger comfort, and ensuring the longevity of various components by reducing wear and tear 1.

Purpose of the 5410318 Vibration Isolator

The Cummins 5410318 Vibration Isolator is specifically designed to reduce vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, enhancing the comfort levels for drivers and passengers, and reducing the wear and tear on various truck components.

Key Features

The 5410318 Vibration Isolator boasts several key features that enhance its performance. Its design incorporates materials that are resilient to the harsh conditions typically encountered in commercial trucking. The isolator is engineered to withstand significant stress and vibration, ensuring reliable performance over time. Additionally, its unique characteristics, such as specific mounting configurations and damping properties, contribute to its effectiveness in vibration reduction.

Benefits of Using the 5410318 Vibration Isolator

Incorporating the 5410318 Vibration Isolator into truck designs offers several advantages. It contributes to improved comfort for drivers and passengers by minimizing the vibrations felt within the cabin. Furthermore, it reduces wear and tear on truck components, leading to enhanced overall performance and longevity of the vehicle. The isolator also plays a role in maintaining the structural integrity of the truck, ensuring safer and more reliable operation 2.

Installation and Integration

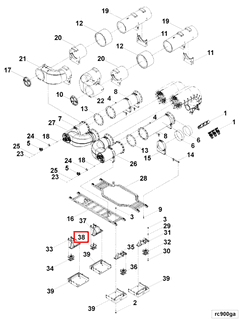

Proper installation and integration of the 5410318 Vibration Isolator are important for its optimal performance. Guidelines for installation include ensuring correct placement and securing the isolator to prevent movement or misalignment. Attention to these details during installation helps in achieving the desired vibration reduction and ensures the isolator functions as intended within the truck’s system.

Troubleshooting and Maintenance

Common issues with the 5410318 Vibration Isolator may include wear and tear or failure to adequately reduce vibrations. Troubleshooting steps involve inspecting the isolator for signs of damage or wear and ensuring it is correctly installed. Maintenance tips include regular inspections to check for any signs of degradation and following manufacturer guidelines for replacement to ensure the longevity and effectiveness of the isolator.

Cummins Corporation

Cummins Corporation is a leading manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation, quality, and customer satisfaction. With a rich history of providing reliable and high-performance components, Cummins plays a significant role in advancing the technology and efficiency of commercial vehicles. The company’s dedication to excellence is evident in its wide range of products, including the 5410318 Vibration Isolator, which embodies Cummins’ standards for quality and performance 3.

Cummins Vibration Isolator 5410318 in Engine Applications

The Cummins Vibration Isolator part number 5410318 is a component designed to mitigate the effects of engine vibrations in various Cummins engine models. This part is engineered to enhance the operational efficiency and longevity of the engines by reducing the transmission of vibrations to the engine mounts and other structural components.

QSK95 and CM2350 Engines

In the QSK95 and CM2350 engines, the Vibration Isolator 5410318 plays a role in maintaining the integrity of the engine’s mounting system. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial sectors. The isolator ensures that the engine’s vibrations are effectively dampened, preventing undue stress on the engine mounts and other critical components. This results in smoother operation and reduced wear and tear, contributing to the overall reliability and lifespan of the engines.

K113 Engine

The K113 engine, another high-performance model in Cummins’ lineup, also benefits significantly from the use of the Vibration Isolator 5410318. This engine is typically employed in demanding environments where consistent performance and durability are paramount. The isolator’s ability to absorb and dissipate vibrations helps in maintaining the engine’s operational stability and protects the surrounding components from the adverse effects of excessive vibrations. This ensures that the K113 engine can operate at peak efficiency, even under strenuous conditions.

Grouping of Engines

The QSK95 and CM2350 engines, while distinct in their specific applications, share common design philosophies and operational requirements. The use of the Vibration Isolator 5410318 in these engines underscores Cummins’ commitment to providing a unified solution for vibration management across different engine models. This approach not only simplifies maintenance and parts management but also ensures a consistent level of performance and reliability.

Role of Part 5410318 Vibration Isolator in Engine Systems

The Part 5410318 Vibration Isolator is instrumental in ensuring the smooth operation of various engine components by mitigating vibrations that can otherwise lead to inefficiencies and potential damage.

When integrated with the Aftertreatment Bracket, the Vibration Isolator helps in stabilizing the bracket, which in turn supports the Aftertreatment system. This stability is essential for the proper functioning of the Aftertreatment components, ensuring they operate within optimal parameters without undue stress from engine vibrations.

In conjunction with the Aftertreatment Device, the Vibration Isolator plays a role in maintaining the device’s integrity. By reducing vibrations, it helps prevent mechanical wear and tear, thereby prolonging the device’s lifespan and ensuring consistent performance.

The Aftertreatment Reactor benefits from the Vibration Isolator by experiencing reduced vibrational forces. This reduction allows the reactor to maintain a stable environment for chemical processes such as the decomposition of harmful emissions, enhancing the overall efficiency of the aftertreatment system.

When part of a Service Kit, the Vibration Isolator contributes to the kit’s goal of enhancing engine performance and longevity. By including this component, the service kit ensures that all interconnected parts—from brackets to reactors—operate in a vibration-dampened environment, leading to improved reliability and reduced maintenance needs.

Conclusion

The Cummins 5410318 Vibration Isolator is a vital component in the operation of commercial trucks and Cummins engines, offering significant benefits in terms of efficiency, comfort, and longevity. Its proper installation, maintenance, and integration into engine systems are key to maximizing its effectiveness and ensuring the overall performance and reliability of the vehicle.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive (5th ed.). Springer Vieweg.

↩ -

Hua Zhao. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Saiful Bari. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.