This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

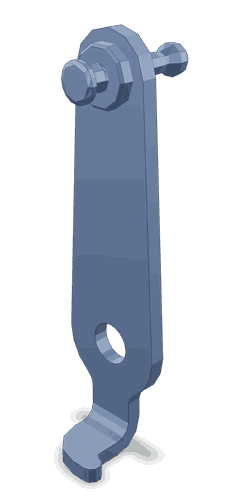

The Bell Crank Lever 3923158, manufactured by Cummins, is a component designed for use in commercial trucks. This part is integral to the mechanical systems that facilitate various truck operations, ensuring efficient and reliable performance.

Basic Concepts of Bell Crank Levers

A Bell Crank Lever is a type of lever that changes the direction of a force. It operates on the principle of mechanical advantage, allowing a smaller force applied at one end to exert a larger force at the other. This lever typically has a perpendicular bend, resembling the shape of a bell clapper, which enables it to redirect force efficiently within a system 1.

Role of the Bell Crank Lever 3923158 in Truck Operation

The Bell Crank Lever 3923158 plays a role in the operation of a truck by interacting with other components and systems. It is involved in the transmission of force, which can be critical for functions such as braking, shifting gears, or operating other mechanical systems within the truck. Its precise function depends on its specific application within the truck’s design 2.

Key Features

The Bell Crank Lever 3923158 is characterized by its robust design and the materials used in its construction. It is typically made from high-strength materials to withstand the rigors of commercial truck use. The design of this lever ensures durability and reliability, with features that may include precision machining for accurate force transmission and corrosion-resistant coatings to enhance longevity 3.

Benefits

The Bell Crank Lever 3923158 offers several benefits in truck operations. Its design contributes to improved efficiency in force transmission, which can lead to better overall performance of the truck’s mechanical systems. The durability and reliability of this component ensure that it can withstand the demands of commercial use, reducing the likelihood of failure and the need for frequent replacements 4.

Troubleshooting and Maintenance

To maintain the Bell Crank Lever 3923158 and troubleshoot common issues, regular inspections are recommended. This includes checking for signs of wear, corrosion, or damage that could affect its performance. Lubrication of moving parts, if applicable, can also help ensure smooth operation. Should any issues arise, addressing them promptly can prevent further damage and maintain the efficiency of the truck’s systems.

About Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has built a reputation for excellence. The company’s dedication to advancing technology and improving the efficiency and reliability of its products underscores its position as a leader in the industry.

Application in Engine Models

-

6B5.9 Engine Series

- The Bell Crank Lever 3923158 is specifically designed to fit within the 6B5.9 engine series. It plays a pivotal role in the engine’s valve train system, facilitating the transfer of motion from the camshaft to the valve mechanism. This ensures that the valves open and close at the correct times, which is essential for maintaining engine performance and efficiency.

-

Other Cummins Engines

- Beyond the 6B5.9, this bell crank lever is also compatible with other Cummins engine models. Its design and functionality remain consistent across different engine types, making it a versatile component in Cummins’ engine lineup. The lever’s precision engineering ensures that it can handle the demands of various engine operations, from light-duty to heavy-duty applications.

Importance in Engine Functionality

The Bell Crank Lever 3923158 is crucial for the following reasons:

- Precision Movement: It ensures that the valve train components move with exact precision, which is vital for the engine’s overall performance.

- Durability: Made from high-quality materials, this lever is built to withstand the rigors of continuous engine operation.

- Compatibility: Its design allows it to fit seamlessly into different engine models, providing a reliable solution across various applications.

Role of Part 3923158 Bell Crank Lever in Engine Systems

The Bell Crank Lever, identified by part number 3923158, is an integral component in the orchestration of engine operations, particularly in the modulation of throttle response. This component acts as a mechanical intermediary, translating linear motion into rotational motion, and vice versa. Its primary function is to facilitate the precise control of the throttle, which is essential for maintaining the desired engine performance.

When the throttle is engaged, either manually by the operator or automatically by the engine control system, the Bell Crank Lever responds by pivoting on its axis. This pivoting action is transferred to the Throttle Bracket, which is securely fastened to the Throttle Control Bracket. The Throttle Control Bracket, in turn, is part of a larger assembly known as the Throttle Kit, which encompasses all the necessary components for throttle operation.

The Bell Crank Lever’s interaction with the Throttle Bracket ensures that the throttle plate within the carburetor or fuel injection system opens and closes in accordance with the demands placed upon the engine. This opening and closing regulate the airflow into the engine, which directly influences the fuel mixture and, consequently, the engine’s power output.

Conclusion

In summary, the Bell Crank Lever (part 3923158) is a pivotal element in the throttle control mechanism, ensuring that the engine responds accurately and efficiently to the throttle inputs, thereby contributing to the overall performance and drivability of the vehicle.

-

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010

↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.