This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2871252 Starting Motor is a vital component in the operation of commercial trucks. It is designed to initiate engine start-up by converting electrical energy into mechanical energy. This motor is integral to ensuring that trucks start reliably and efficiently, which is essential for maintaining operational schedules and productivity in commercial settings 3.

Basic Concepts of Starting Motors

Starting motors operate on the principle of converting electrical energy into mechanical energy to start an engine. They consist of an electric motor and a gear reduction assembly. When the ignition is turned on, the motor engages, spinning the engine’s flywheel to start the combustion process. This conversion of energy is fundamental to the operation of internal combustion engines 2.

Purpose of the Cummins 2871252 Starting Motor

The Cummins 2871252 Starting Motor plays a role in the operation of a truck by initiating engine start-up. It ensures that the engine cranks smoothly and efficiently, which is essential for reliable operation. This motor is specifically engineered to handle the demands of commercial truck engines, providing the necessary torque and speed to start the engine under various conditions 3.

Key Features

The Cummins 2871252 Starting Motor is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality construction materials, ensuring durability and longevity. The motor is built to withstand the rigors of commercial use, with features such as robust gearing and precise electrical components. Additionally, it may include unique attributes like advanced cooling systems or enhanced electrical insulation to improve performance 1.

Benefits

Using the Cummins 2871252 Starting Motor offers several benefits. It provides improved starting performance, ensuring that the engine starts quickly and reliably. The motor’s durable construction contributes to its longevity, reducing the need for frequent replacements. Additionally, its efficient design helps to minimize electrical draw, contributing to overall fuel efficiency and reducing operational costs 3.

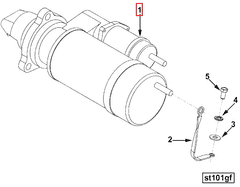

Installation Process

Proper installation of the Cummins 2871252 Starting Motor involves several steps. Begin by ensuring the truck is turned off and the battery is disconnected to prevent electrical accidents. Remove the old starting motor, taking note of any wiring or mounting positions. Install the new motor in the reverse order of removal, ensuring all connections are secure and tight. Reconnect the battery and test the motor to confirm proper operation 3.

Troubleshooting Common Issues

Common issues with the Cummins 2871252 Starting Motor may include difficulty starting, unusual noises, or electrical problems. To troubleshoot, first, check the battery connections and ensure they are clean and tight. Inspect the motor for any signs of damage or wear. If the motor makes unusual noises, it may indicate a problem with the gear assembly or internal components, requiring further inspection or replacement 3.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 2871252 Starting Motor, regular maintenance is important. This includes inspecting the motor for signs of wear or damage, ensuring all connections are secure, and cleaning the motor to remove any dirt or debris. Additionally, following the manufacturer’s recommended service intervals for inspection and maintenance will help to prevent issues and ensure reliable operation 3.

Safety Considerations

When working with the Cummins 2871252 Starting Motor, several safety considerations should be kept in mind. Always disconnect the battery before beginning any work to prevent electrical accidents. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Follow all manufacturer guidelines for handling and installation to ensure safe and effective use of the motor 3.

Compatibility of Cummins Part 2871252 with Various Engine Models

The Cummins part 2871252, a Starting Motor, is designed to be compatible with a range of engine models, ensuring reliable performance across different applications. This part is engineered to fit seamlessly with the following engines:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

ISX Series

- ISX CM570

KTA19 Series

- KTA19GC

- KTA19GC CM558

M11 Series

- M11 CELECT PLUS

N14 Series

- N14 G

- N14 MECHANICAL

NH/NT 855 Series

- NH/NT 855

QSM11 Series

- QSM11 CM570

QSNT14 Series

- QSNT14 CM876 N102

This compatibility ensures that the Starting Motor can be used across various engine models, providing a reliable and efficient starting solution. The design and specifications of the part 2871252 are tailored to meet the demands of these engines, ensuring optimal performance and longevity 3.

Understanding the Role of Part 2871252 Starting Motor in Engine Systems

The part 2871252 Starting Motor is an essential component in the operation of various engine systems. Its primary function is to initiate the engine’s operation by converting electrical energy into mechanical energy, which in turn rotates the engine’s crankshaft. This action is fundamental for the combustion process to begin 2.

Integration with On-Board Spares Kit

When integrated with an on-board spares kit, the starting motor ensures that the vehicle is prepared for unforeseen mechanical failures. The on-board spares kit typically includes replacement parts for critical components, and the starting motor is often a part of this kit due to its importance in engine start-up. Having a spare starting motor on hand allows for quick replacement in the event of a failure, minimizing downtime and ensuring the vehicle remains operational 3.

Synergy with the Motor Component

The starting motor works in conjunction with the main motor component of the engine system. Once the starting motor has initiated the engine, the main motor takes over, sustaining the engine’s operation through continuous combustion cycles. The starting motor’s efficiency directly impacts the main motor’s ability to start reliably, highlighting the interdependence of these components 2.

Starting System Functionality

In the broader starting system, the starting motor is activated by the ignition switch, which sends an electrical signal to the starter solenoid. The solenoid then engages the starting motor, which begins to turn the crankshaft. This process requires precise coordination with other components such as the battery, which supplies the necessary electrical power, and the flywheel, which helps to smooth out the engine’s rotational motion 2.

Ensuring Reliable Engine Start-Up

The reliability of the starting motor is paramount for consistent engine performance. It must be capable of withstanding the high currents and mechanical stresses involved in starting the engine. Regular maintenance and inspection of the starting motor are therefore necessary to ensure it functions correctly within the engine system 3.

Conclusion

The Cummins 2871252 Starting Motor plays a significant role in the initiation and reliable operation of engine systems. Its integration with on-board spares, collaboration with the main motor, and function within the starting system underscore its importance in maintaining vehicle performance and readiness. Regular maintenance, proper installation, and adherence to safety guidelines are essential for ensuring the longevity and efficiency of this critical component 3.

-

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ ↩ ↩ ↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.