This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

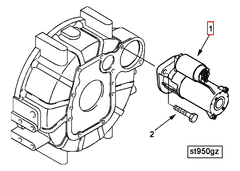

The Cummins 4900574 Starting Motor is a component designed for use in commercial trucks. It serves the purpose of initiating engine cranking, which is a fundamental requirement for starting the engine. Its significance lies in ensuring that the truck can start reliably under a variety of conditions, which is vital for the operational efficiency of commercial vehicles 1.

Basic Concepts of Starting Motors

Starting motors are integral to the operation of internal combustion engines. They function by converting electrical energy from the vehicle’s battery into mechanical energy to crank the engine. This process involves several components, including the solenoid, which acts as a switch to engage the starter, the armature, which rotates to create mechanical motion, and the commutator, which ensures the continuous rotation of the armature by reversing the current direction as needed 2.

Purpose of the Cummins 4900574 Starting Motor

The Cummins 4900574 Starting Motor plays a role in the operation of a truck by initiating engine cranking. This is achieved through the conversion of electrical energy into mechanical energy, which turns the engine’s flywheel. Reliable starts are ensured by the motor’s design, which is capable of performing under various conditions, including cold starts and high-load situations 3.

Key Features

The Cummins 4900574 Starting Motor is characterized by several key features. These include a robust construction that enhances durability, a high torque output that ensures efficient engine cranking, and compatibility with specific Cummins engines. These features contribute to the motor’s reliability and performance in commercial truck applications 4.

Benefits

The advantages of the Cummins 4900574 Starting Motor include improved starting performance, which is crucial for the timely operation of commercial trucks. It also offers enhanced reliability, reducing the likelihood of starting failures. Additionally, the motor requires less maintenance and exhibits increased longevity compared to other starting motors, making it a cost-effective choice for fleet operators.

Installation and Integration

Proper installation and integration of the Cummins 4900574 Starting Motor into commercial truck engines involve following recommended procedures. This includes ensuring correct alignment, securing all connections, and verifying electrical compatibility. The use of appropriate tools is necessary, and awareness of potential challenges, such as tight spaces or complex wiring, can facilitate a smoother installation process.

Troubleshooting Common Issues

Common problems associated with starting motors, such as slow cranking, intermittent starting, or complete failure to start, can often be traced to issues with the battery, connections, or the motor itself. Troubleshooting steps may involve checking the battery’s charge, inspecting wiring and connections for corrosion or damage, and testing the motor’s functionality. Diagnostic techniques, such as using a multimeter to check electrical continuity, can aid in identifying the root cause of the issue.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 4900574 Starting Motor, routine maintenance practices are recommended. These include regular inspection for signs of wear or damage, cleaning to remove any debris that may affect operation, lubrication of moving parts to reduce friction, and replacement of worn components as needed. Adhering to these maintenance tips can help prevent unexpected failures and extend the motor’s service life.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its diesel engines and related components. With a history of innovation and a commitment to quality, Cummins has built a reputation for manufacturing reliable and efficient products. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the field of diesel engine manufacturing.

Compatibility of Cummins Part 4900574 with Various Engine Models

The Cummins part 4900574, a Starting Motor, is designed to be compatible with a range of engine models, ensuring reliable performance across different applications. This part is engineered to fit seamlessly with the following engines:

A1400 and A1700 Engines

The Starting Motor 4900574 is specifically tailored for use with the A1400 and A1700 engines. These engines, known for their robust design and efficiency, benefit from the reliable starting capabilities provided by this motor. The integration of the 4900574 ensures smooth and efficient engine startups, enhancing the overall operational efficiency of these models.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines are designed to work optimally with the Cummins part 4900574. These engines, which are part of a series recognized for their power and reliability, are equipped with this starting motor to ensure that they can start reliably under various conditions. The 4900574 is engineered to handle the demands of these higher-capacity engines, providing the necessary power to initiate the engine’s operation effectively.

Grouping for Efficiency

When considering the compatibility of the Cummins part 4900574 with the A1400, A1700, A2000, and A2300 engines, it is important to note that these engines share common design principles and operational requirements. The starting motor is designed to meet these shared needs, ensuring that it can be used across these models without modification. This grouping allows for streamlined maintenance and repair processes, as technicians can use the same part for multiple engine types, reducing inventory complexity and ensuring consistent performance.

Role of Part 4900574 Starting Motor in Engine Systems

The part 4900574 Starting Motor is an essential component in the ignition process of various engine systems. When the ignition key is turned, the starting motor engages with the flywheel or flexplate, initiating the rotation of the engine’s crankshaft. This action compresses the air-fuel mixture within the cylinders, setting the stage for combustion.

In gasoline engines, the starting motor’s role is to overcome the engine’s inertia, allowing the pistons to reach the necessary speed for ignition. Once the engine is running, the starting motor disengages, and the engine continues to operate under its own power.

In diesel engines, the starting motor must generate sufficient torque to compress the air in the cylinders to the point where it becomes hot enough for diesel fuel to ignite spontaneously. The starting motor ensures that the engine reaches the required compression ratios before fuel injection occurs.

For hybrid and electric vehicles, the starting motor often doubles as a generator, assisting in the regeneration of energy during braking and providing supplementary power during acceleration. In these systems, the starting motor works in conjunction with the battery and electric motor to optimize performance and efficiency.

In all engine types, the starting motor is integral to the initial phase of operation, ensuring a smooth and reliable start. Its interaction with other components such as the battery, ignition system, and engine control unit (ECU) highlights its importance in the overall functionality of the engine system.

Conclusion

The Cummins 4900574 Starting Motor is a critical component for the reliable operation of commercial trucks. Its robust construction, high torque output, and compatibility with specific Cummins engines make it a reliable and efficient choice for fleet operators. Proper installation, maintenance, and troubleshooting practices are essential to ensure the motor’s optimal performance and longevity.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Michael Hilgers, The Diesel Engine Second Edition (Springer Nature, 2023).

↩ -

Gunnar Stiesch, Modeling Engine Spray and Combustion Processes (Springer Verlag, 2003).

↩ -

Konrad Reif Ed, Diesel Engine Management Systems and Components (Springer Vieweg, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.