This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4968796 Hydraulic Motor is a specialized component designed for use in commercial trucks. It is integral to various hydraulic systems within these vehicles, contributing to their overall functionality and efficiency. This motor is particularly significant due to its role in converting hydraulic pressure into mechanical motion, which is vital for the operation of numerous truck systems 1.

Basic Concepts of Hydraulic Motors

Hydraulic motors are devices that transform hydraulic pressure into rotational mechanical motion. They are a key component in hydraulic systems, where they work alongside pumps, valves, and actuators to perform various tasks. The operation of a hydraulic motor involves the use of pressurized fluid, typically oil, which is directed into the motor’s chambers. As the fluid enters, it exerts force on the motor’s internal components, causing them to rotate and produce mechanical motion. This motion can then be used to drive other machinery or systems within the vehicle 2.

Purpose of the Cummins 4968796 Hydraulic Motor

The Cummins 4968796 Hydraulic Motor serves a specific role in the operation of commercial trucks. It is utilized in various truck systems, including braking systems, steering mechanisms, and other hydraulic-driven components. By converting hydraulic pressure into mechanical motion, this motor enables these systems to function efficiently and effectively. Its applications are diverse, ranging from enhancing vehicle control to improving the performance of auxiliary systems 3.

Key Features

The Cummins 4968796 Hydraulic Motor is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials, ensuring robustness and longevity. The motor is engineered to operate under a wide range of conditions, making it suitable for the demanding environments typical of commercial truck operations. Additionally, it features precise manufacturing tolerances, which contribute to its efficiency and reliability 4.

Benefits

The Cummins 4968796 Hydraulic Motor offers several benefits that contribute to improved truck operations. Its efficient conversion of hydraulic pressure into mechanical motion leads to enhanced system performance. The motor’s reliable operation reduces the likelihood of system failures, contributing to overall vehicle reliability. Furthermore, its durable construction ensures longevity, reducing the need for frequent replacements and maintenance 5.

Installation and Integration

Proper installation and integration of the Cummins 4968796 Hydraulic Motor into truck hydraulic systems are crucial for optimal performance. Installation should follow manufacturer guidelines to ensure correct alignment and secure mounting. Integration involves connecting the motor to the hydraulic system, ensuring that all connections are tight and secure to prevent leaks. Careful attention to these steps helps maintain system efficiency and safety 6.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the Cummins 4968796 Hydraulic Motor operates at peak performance. Common issues may include leaks, unusual noises, or decreased efficiency. Troubleshooting these problems often involves checking connections, inspecting for wear or damage, and ensuring the motor is properly lubricated. Maintenance practices, such as regular fluid changes and component inspections, help prevent issues and extend the motor’s lifespan 7.

Safety Considerations

When working with hydraulic motors, including the Cummins 4968796, safety is paramount. Proper handling and maintenance procedures should be followed to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before performing maintenance, and following all manufacturer safety guidelines. Awareness of the high pressures involved in hydraulic systems is crucial to maintaining a safe working environment 8.

Environmental Impact

Hydraulic motors, including the Cummins 4968796, have an environmental impact that is influenced by their design and operation. Efforts to minimize this impact include improving energy efficiency and reducing emissions. The use of high-efficiency motors can lead to lower energy consumption, while advancements in hydraulic fluid technology aim to reduce environmental harm. Manufacturers are increasingly focusing on designing motors that not only perform well but also have a reduced environmental footprint 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins offers a wide range of products designed to meet the needs of various applications. The company’s commitment to innovation, quality, and customer satisfaction has established it as a trusted name in the industry, with the Cummins 4968796 Hydraulic Motor being a testament to its expertise in hydraulic technology 10.

Compatibility with Engine Models

The Cummins Hydraulic Motor part number 4968796 is designed to integrate seamlessly with several engine models, ensuring optimal performance and reliability. This hydraulic motor is engineered to work with the QSK19 CM2350 K114 and QSK19 CM850 MCRS engines, providing essential functionality for various applications.

QSK19 CM2350 K114

The QSK19 CM2350 K114 engine benefits from the hydraulic motor’s precision and efficiency. This engine model is known for its robust performance and reliability, making it suitable for heavy-duty applications. The hydraulic motor complements the engine’s capabilities by offering smooth and consistent power delivery, enhancing the overall operational efficiency.

QSK19 CM850 MCRS

Similarly, the QSK19 CM850 MCRS engine is designed to work in tandem with the hydraulic motor 4968796. This engine model is engineered for high-performance applications, and the hydraulic motor ensures that it operates at peak efficiency. The integration of this hydraulic motor with the QSK19 CM850 MCRS engine provides a reliable power source, contributing to the engine’s superior performance and durability.

Grouping for Enhanced Performance

Both the QSK19 CM2350 K114 and QSK19 CM850 MCRS engines are part of Cummins’ lineup of high-performance engines. The hydraulic motor 4968796 is specifically designed to enhance the functionality of these engines, ensuring that they deliver the best possible performance in their respective applications. By using this hydraulic motor, operators can expect improved efficiency, reduced downtime, and extended service life for their engines.

Role of Part 4968796 Hydraulic Motor in Engine Systems

In the context of engine systems, the integration of part 4968796 Hydraulic Motor is instrumental in ensuring efficient and reliable operation. This hydraulic motor works in conjunction with several key components to maintain optimal performance.

Interaction with the Filter

The hydraulic motor relies on clean hydraulic fluid to operate effectively. The filter plays a significant role in this process by removing contaminants from the fluid. As the hydraulic motor circulates the fluid, the filter ensures that any particles or debris are captured, preventing them from causing wear or damage to the motor’s internal components. Regular maintenance of the filter is essential to sustain the hydraulic motor’s efficiency and longevity 11.

Lubricating Oil’s Contribution

Lubricating oil is another vital component that supports the hydraulic motor. It reduces friction between moving parts, minimizes wear, and dissipates heat generated during operation. The hydraulic motor depends on a consistent supply of lubricating oil to maintain its performance and prevent overheating. The quality and viscosity of the lubricating oil must be appropriate for the specific requirements of the hydraulic motor to ensure smooth operation 12.

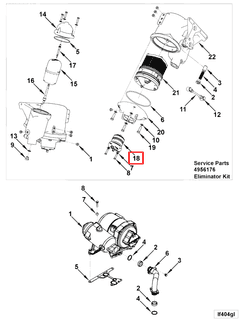

Filter Kit Integration

A filter kit, which typically includes multiple filters and associated components, enhances the filtration process for the hydraulic system. By incorporating a filter kit, the hydraulic motor benefits from improved fluid cleanliness, which translates to reduced maintenance intervals and increased reliability. The filter kit may also include bypass valves and pressure relief valves, which help protect the hydraulic motor from damage due to contaminants or excessive pressure 13.

Lubricating Oil Filter Head Functionality

The lubricating oil filter head is a critical component in the hydraulic system that houses the lubricating oil filter. It ensures that the oil is properly filtered before it reaches the hydraulic motor. The filter head often includes features such as pressure gauges and bypass valves to monitor and maintain the integrity of the filtration process. This component helps in maintaining the quality of the lubricating oil, thereby supporting the hydraulic motor’s performance and durability 14.

Conclusion

In summary, the Cummins 4968796 Hydraulic Motor is a critical component in the operation of commercial trucks, providing efficient and reliable hydraulic power for various systems. Its integration with compatible engine models enhances overall performance and durability. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this hydraulic motor. Additionally, ongoing efforts to improve energy efficiency and reduce environmental impact demonstrate Cummins’ commitment to innovation and sustainability in hydraulic technology.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367450.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.