This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

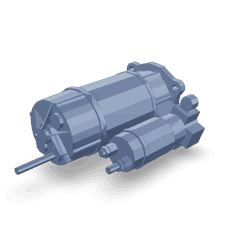

The Cummins 5593352 Starting Motor is a component designed for use in commercial trucks. It serves the purpose of initiating engine operation, which is a fundamental requirement for the vehicle’s functionality. The significance of this starting motor lies in its ability to reliably start the engine under a variety of conditions, ensuring that the truck can operate efficiently and consistently.

Basic Concepts of Starting Motors

Starting motors operate on the principle of converting electrical energy into mechanical motion to initiate engine operation. This process involves several components, including the starter solenoid, the starter motor, and the pinion gear, which engages with the engine’s flywheel. When the ignition is turned on, electrical current flows through the solenoid, which then activates the starter motor. The starter motor’s armature rotates, and the pinion gear meshes with the flywheel, turning the engine over until it starts 1.

Purpose and Role of the Cummins 5593352 Starting Motor

The Cummins 5593352 Starting Motor is specifically engineered to engage with the truck’s engine to facilitate starting. It is designed to handle the high torque requirements of large commercial engines, ensuring that the engine can be started reliably even in cold weather or after long periods of inactivity. The motor’s design allows it to provide the necessary cranking speed for the engine to ignite and run smoothly 4.

Key Features

The Cummins 5593352 Starting Motor is characterized by its robust design and construction, which includes high-quality materials that enhance its durability and performance. It is built to withstand the rigors of commercial truck use, with features such as a heavy-duty armature and commutator, and a durable housing. The motor is also designed to meet specific electrical requirements, ensuring compatibility with the truck’s electrical system. Unique characteristics of this starting motor may include advanced cooling systems or noise reduction features 2.

Benefits of Using the Cummins 5593352 Starting Motor

Utilizing the Cummins 5593352 Starting Motor in commercial trucks offers several advantages. Its reliability ensures that the engine can be started consistently, reducing downtime. The motor’s efficiency contributes to fuel savings, while its durability means it can withstand the demands of heavy-duty use. Performance enhancements provided by this starting motor can lead to improved overall truck operation 3.

Troubleshooting and Maintenance Suggestions

To maintain optimal performance of the Cummins 5593352 Starting Motor, regular maintenance is recommended. This includes checking electrical connections for corrosion or looseness, ensuring the battery is in good condition, and inspecting the starter motor for signs of wear or damage. Common issues with starting motors can often be traced to the battery, connections, or the motor itself. Diagnostic procedures may involve testing electrical circuits and the motor’s functionality. Preventive measures include keeping the motor clean and ensuring it is well-lubricated where applicable 4.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its commitment to innovation and quality. The company’s product range extends beyond engines to include aftermarket parts, technology solutions, and services that support the automotive and commercial vehicle industries. Cummins’ reputation is built on its dedication to customer satisfaction and its continuous pursuit of technological advancement.

Compatibility with Cummins Engines

The Cummins part 5593352, a Starting Motor, is designed to be compatible with a range of Cummins engines. This part is engineered to ensure reliable and efficient engine starts across various models.

For the K19 series, the 5593352 Starting Motor is specifically tailored to fit the K19 engines, ensuring seamless integration and optimal performance. Similarly, for the QSK19 CM2350 K114 and QSK19 CM2350 K144G engines, this starting motor is engineered to meet the specific requirements of these models, providing robust and dependable starting capabilities.

In the case of the QSK19 CM500 and QSK19 CM850 MCRS engines, the 5593352 Starting Motor is designed to handle the higher power demands of these engines, ensuring that the starting process is both quick and efficient. This part is also compatible with the QSK19G engine, offering a consistent and reliable starting solution across this model as well.

Overall, the Cummins part 5593352 Starting Motor is a versatile and high-performance component that is engineered to fit and function optimally with a variety of Cummins engine models, ensuring reliable engine starts and long-term durability.

Role of Part 5593352 Starting Motor in Engine Systems

The part 5593352 starting motor is integral to the functionality of various engine systems, facilitating the initial rotation of the engine to initiate combustion. This component interfaces with several key systems to ensure a smooth start-up process.

Interaction with the Battery System

The starting motor draws electrical power from the vehicle’s battery. This power is essential for the motor to generate the torque needed to turn the engine’s flywheel. Efficient power transfer from the battery to the starting motor ensures reliable engine starts, especially in cold conditions where battery performance can be compromised.

Connection to the Starter Solenoid

The starter solenoid acts as an intermediary between the starting motor and the battery. When the ignition key is turned, the solenoid engages, allowing a high current to flow from the battery to the starting motor. This engagement is rapid, ensuring that the starting motor receives the necessary power almost instantaneously to begin cranking the engine.

Integration with the Flywheel

Once powered, the starting motor engages with the flywheel through the starter gear. The flywheel, connected to the crankshaft, begins to rotate, which in turn starts the pistons’ movement within the cylinders. This rotational motion is fundamental for the engine to reach the required RPM for combustion to occur.

Coordination with the Ignition System

As the engine cranks, the ignition system springs into action. The starting motor’s consistent cranking speed ensures that the ignition system can time the spark delivery to the cylinders accurately. This synchronization is vital for efficient fuel ignition and smooth engine start-up.

Role in the Fuel System

While the starting motor itself does not directly interact with the fuel system, its reliable operation ensures that the engine reaches the necessary RPM for the fuel injectors or carburetor to begin delivering fuel. This seamless transition from cranking to running is essential for a trouble-free start.

Impact on the Exhaust System

A well-functioning starting motor contributes to a cleaner start-up process, minimizing the release of unburned fuel into the exhaust system. This not only enhances emissions performance but also protects the catalytic converter from unnecessary stress during start-up.

Influence on the Cooling System

Although indirectly, the starting motor’s efficiency affects the cooling system. A quick and smooth start-up reduces the time the engine operates without adequate coolant flow, thereby protecting the engine from potential overheating issues during the initial phases of operation.

Conclusion

In summary, the part 5593352 starting motor is a pivotal component that ensures the engine systems work in harmony during the start-up phase, contributing to overall vehicle performance and reliability.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.