This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3251594 Lock Nut is a specialized component designed for use in commercial truck maintenance. Its purpose is to provide a secure fastening solution in various truck systems, ensuring that components remain firmly in place under operational conditions. The significance of this lock nut lies in its ability to enhance the reliability and safety of truck operations by preventing loosening of fasteners due to vibration and other dynamic forces 1.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners that are designed to resist loosening under vibration and dynamic loads. They function by creating additional friction or deformation at the interface between the nut and the threaded component, which helps to maintain the integrity of the fastening. Lock nuts find applications in a wide range of mechanical systems where secure fastening is required to ensure safety and performance 2.

Purpose of the Cummins 3251594 Lock Nut

The Cummins 3251594 Lock Nut plays a specific role in the operation of commercial trucks by securing components that are subject to significant vibration and dynamic loads. It is commonly used in applications where the loosening of fasteners could lead to operational issues or safety concerns. The lock nut ensures that critical components remain securely fastened, contributing to the overall reliability of the truck 3.

Key Features

The Cummins 3251594 Lock Nut is characterized by several distinctive features that enhance its performance. It is typically made from high-strength materials to withstand the rigors of commercial truck operation. The design may include features such as a nylon insert or deformed threads that provide additional resistance to loosening. These attributes contribute to the lock nut’s effectiveness in maintaining secure fastenings 4.

Benefits

Using the Cummins 3251594 Lock Nut offers several advantages. It provides increased security for fastened components, ensuring that they remain in place under vibration and dynamic loads. The lock nut’s design also contributes to resistance against loosening, which can extend the lifespan of fastened components and reduce the need for frequent maintenance. Additionally, its durability in harsh operating conditions makes it a reliable choice for commercial truck applications.

Installation Guidelines

Proper installation of the Cummins 3251594 Lock Nut is crucial for optimal performance and safety. To install, first, ensure that the threaded component is clean and free of debris. Apply the appropriate torque specification to the lock nut to achieve the desired level of tension without over-tightening. It is important to follow manufacturer guidelines to ensure that the lock nut functions as intended.

Troubleshooting and Maintenance

Common issues with lock nuts may include loosening due to insufficient torque or environmental factors. Troubleshooting involves checking the torque settings and ensuring that the lock nut is compatible with the application. Regular maintenance, such as periodic inspection and re-torquing, can help prolong the life of the Cummins 3251594 Lock Nut and ensure continued secure fastening.

Safety Considerations

When installing or maintaining the Cummins 3251594 Lock Nut, it is important to observe safety practices. This includes using the correct tools and following torque specifications to avoid over-tightening, which can damage threads or components. Additionally, wearing appropriate personal protective equipment (PPE) is recommended to protect against injury during installation and maintenance procedures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of vehicles and equipment.

Lock Nut 3251594 Compatibility with Cummins Engines

The Lock Nut part number 3251594, manufactured by Cummins, is a critical component designed to ensure secure fastening in various engine applications. This part is engineered to fit seamlessly with several Cummins engines, providing a reliable solution for maintaining the integrity of engine assemblies.

N14 CELECT PLUS and QSB5.9 CM850 Engines

The Lock Nut 3251594 is compatible with both the N14 CELECT PLUS and QSB5.9 CM850 engines. These engines are known for their robust performance and are widely used in heavy-duty applications. The lock nut ensures that critical components remain securely fastened under varying operational conditions, thereby enhancing the longevity and reliability of these engines.

4B3.9 and V903 Engines

Similarly, the Lock Nut 3251594 is also suitable for the 4B3.9 and V903 engines. These engines are designed for versatility and efficiency, often used in a range of industrial and commercial applications. The lock nut’s precision fit and secure fastening capabilities are essential for maintaining the operational integrity of these engines, ensuring they perform optimally over extended periods.

Application Considerations

When installing the Lock Nut 3251594 in any of these engines, it is crucial to follow the manufacturer’s guidelines to ensure proper torque specifications and secure fastening. This will help prevent loosening and potential engine damage, ensuring the engines operate at peak efficiency.

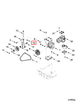

Role of Part 3251594 Lock Nut in Engine Systems

The part 3251594 Lock Nut is instrumental in securing various components within engine systems, ensuring stability and preventing unwanted movement that could lead to inefficiencies or failures.

In the belt tensioner system, the lock nut is used to maintain the correct tension on the belts that drive accessories such as the alternator and water pump. This ensures optimal performance and longevity of the belts and the components they drive.

For the control linkage mounting, the lock nut plays a significant role in securing the linkage to the engine or transmission. This is essential for precise control of various engine functions, such as throttle response and gear shifting.

In applications involving the fan, the lock nut is often employed to secure the fan to the water pump or directly to the engine. This ensures that the fan operates efficiently to cool the engine, preventing overheating.

When it comes to engine mounting, the lock nut is utilized to secure the engine to the vehicle’s frame. This is vital for maintaining the engine’s position and absorbing vibrations, which contributes to the overall stability and performance of the vehicle.

In the alternator system, the lock nut is used to secure the alternator to the engine. This ensures that the alternator remains in the correct position to effectively charge the battery and power the electrical systems of the vehicle.

For panel installations, such as raw water pump panels, the lock nut is employed to secure the panel to the engine compartment. This ensures that the panel remains in place and operates efficiently.

In addressing noise reduction, the lock nut is often used in conjunction with vibration dampeners and mounts to secure components in place, minimizing unwanted noise and vibrations that can affect both performance and comfort.

In the pump system, whether it be a fuel pump or a water pump, the lock nut is used to secure the pump to the engine or its mounting bracket. This ensures that the pump operates efficiently and remains in the correct position.

Lastly, in transmission systems, the lock nut is utilized to secure various components, such as linkage and mounts, ensuring that the transmission operates smoothly and efficiently.

Conclusion

The Cummins 3251594 Lock Nut is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design and features ensure secure fastening under dynamic conditions, contributing to the reliability and safety of the vehicles it is used in. Proper installation, maintenance, and adherence to safety practices are essential to maximize the benefits of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015.

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023.

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.