This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Nut Fastener 3253116, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part plays a role in securing various connections within the truck’s systems.

Basic Concepts of Tube Nut Fasteners

Tube nut fasteners are mechanical components used to secure tubing and piping in automotive and industrial applications. They function by providing a tight seal and secure connection, which is important for systems that transport fluids or gases under pressure. These fasteners are designed to withstand significant stress and environmental conditions, ensuring the integrity of the connections they maintain 1.

Purpose of the 3253116 Tube Nut Fastener

This part is utilized in commercial trucks to secure connections in systems where fluid or gas transport is necessary. Its application areas include fuel lines, hydraulic systems, and other components where secure and leak-free connections are required. The fastener contributes to the overall reliability and safety of the truck’s operation by maintaining these connections under various operating conditions.

Key Features

The 3253116 is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring resistance to corrosion and wear. The design includes precision threading and a robust nut mechanism, which allows for a secure fit on the tubing. Additionally, the fastener may incorporate features such as gaskets or O-rings to improve the seal and prevent leaks.

Benefits

The advantages of this part include its durability, which is a result of the high-quality materials and construction. It offers ease of installation, with a design that allows for quick and secure fitting without the need for specialized tools. The reliability of the fastener in heavy-duty applications is demonstrated by its ability to maintain secure connections under pressure and in demanding environments.

Installation Process

To install the 3253116, begin by ensuring the tubing is clean and free of debris. Align the fastener with the tubing and thread it on by hand to avoid cross-threading. Once hand-tight, use the appropriate tool to tighten the fastener to the manufacturer’s specified torque. It is important to follow best practices, such as not over-tightening, to prevent damage to the tubing or the fastener itself.

Troubleshooting Common Issues

Common issues with tube nut fasteners may include leakage or loosening over time. To address leakage, inspect the fastener for signs of wear or damage and ensure that any gaskets or O-rings are in good condition. If loosening is detected, re-tighten the fastener to the correct torque specification. In cases where the fastener is damaged, replacement may be necessary to restore a secure connection.

Maintenance Tips

Regular maintenance of the 3253116 involves periodic inspection for signs of wear, corrosion, or leaks. Cleaning the fastener and surrounding area can prevent the buildup of contaminants that may affect performance. It is also advisable to check the torque of the fastener during routine maintenance to ensure it remains secure.

Compatibility and Applications

The 3253116 is typically used in commercial trucks for applications that require secure fluid or gas connections. It is compatible with various systems within the truck, including but not limited to, fuel delivery, hydraulic controls, and other components where tubing connections are present.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for commercial vehicle operators and manufacturers 2.

Tube Nut Fastener 3253116 in Cummins Engines

The 3253116, manufactured by Cummins, is a component in various Cummins engine models. This part is integral to the assembly and functionality of the engine, ensuring secure connections and maintaining structural integrity.

N14 MECHANICAL

In the N14 MECHANICAL engine, the 3253116 plays a role in securing various components. Its design and placement are important for the engine’s operational efficiency and longevity. This part is typically used in areas where high-strength fastening is required, ensuring that parts remain tightly secured under the engine’s operational stresses.

The 3253116 is engineered to withstand the demanding conditions within the engine, including high temperatures and pressures. Its robust construction ensures that it can maintain its integrity over extended periods, contributing to the overall reliability of the N14 MECHANICAL engine.

The use of this fastener in the N14 MECHANICAL engine highlights Cummins’ commitment to quality and durability, ensuring that the engine operates smoothly and efficiently.

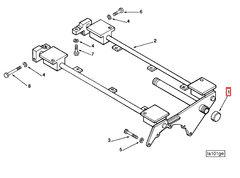

Role of Part 3253116 Tube Nut Fastener in Engine Systems

The part 3253116 Tube Nut Fastener is integral to the secure assembly and operation of various engine components. It ensures the stability and integrity of the engine arrangement by fastening tubes and other critical elements, thereby facilitating a robust connection between different parts.

In the context of the lifting mechanism, the Tube Nut Fastener plays a role. It secures the lifting points, ensuring that the engine can be safely and efficiently lifted during maintenance or installation procedures. This is particularly important for heavy-duty engines where precise and secure fastening is essential.

For the Electronic Brake Module (EBM) sub-base, the Tube Nut Fastener is used to attach the module securely to the chassis. This ensures that the EBM remains stable and operates correctly, contributing to the overall safety and performance of the braking system.

In the front engine support system, the Tube Nut Fastener is employed to connect the engine to the front support structure. This connection is vital for absorbing vibrations and ensuring that the engine remains aligned and securely mounted, which is essential for both performance and longevity.

Lastly, within the subbase assembly, the Tube Nut Fastener is utilized to join various components together, providing a solid foundation for the engine. This ensures that all parts work in unison, enhancing the engine’s efficiency and reliability.

Conclusion

The 3253116 Tube Nut Fastener is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure connections, durability, and ease of installation, contributing to the overall reliability and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.