This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

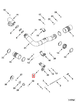

The Cummins 3285627 Lock Nut is a specialized component designed for use in commercial truck maintenance. Its purpose is to secure fasteners in place, preventing them from loosening due to vibrations or other dynamic forces encountered during operation. This part is significant in maintaining the integrity and safety of truck assemblies, ensuring that critical components remain firmly attached under various operating conditions 1.

Basic Concepts of Lock Nuts

Lock nuts, also known as prevailing torque nuts or self-locking nuts, are designed to resist loosening caused by vibration and dynamic loads. They achieve this through various mechanisms, such as nylon inserts, deformed threads, or locking patches. These features create additional friction between the nut and the fastener, enhancing the security of the connection 2. Lock nuts find applications in a wide range of mechanical systems, including automotive, aerospace, and industrial machinery, where maintaining secure fastening is crucial.

Purpose of the Cummins 3285627 Lock Nut

The Cummins 3285627 Lock Nut plays a specific role in the operation and maintenance of commercial trucks. It is typically used in applications where standard nuts may not provide sufficient resistance to loosening. This lock nut is important in ensuring that critical components, such as engine mounts, exhaust systems, and chassis parts, remain securely fastened. Its use helps prevent unexpected failures and enhances the overall reliability of the truck 3.

Key Features

The Cummins 3285627 Lock Nut boasts several key features that set it apart from standard nuts. Its design includes a nylon insert that provides additional friction, preventing the nut from loosening over time. The material composition is robust, ensuring durability under harsh operating conditions. Additionally, the lock nut may feature unique thread patterns or locking mechanisms that further enhance its effectiveness in securing fasteners 4.

Benefits of Using Lock Nuts

Incorporating lock nuts into truck assemblies offers several advantages. Enhanced security against loosening is a primary benefit, as lock nuts are designed to withstand vibrations and dynamic loads that could cause standard nuts to become undone. Improved durability is another advantage, as lock nuts are often made from high-strength materials that can endure the rigors of commercial truck operation. Reliability in various operating conditions is also a key benefit, ensuring that critical components remain securely fastened regardless of the environment 1.

Installation Guidelines

Proper installation of the Cummins 3285627 Lock Nut is crucial for optimal performance. The following steps outline the installation process:

- Ensure the mating threads are clean and free of debris.

- Apply the appropriate thread lubricant if specified.

- Use a torque wrench to tighten the lock nut to the manufacturer’s specified torque settings.

- Double-check the tightness to ensure the nut is securely fastened.

Tools required for installation include a torque wrench, a socket set compatible with the nut size, and any necessary thread lubricants 2.

Troubleshooting Common Issues

Common problems associated with lock nuts include loosening and damage. If a lock nut appears loose, it should be re-tightened to the specified torque settings. If damage is observed, such as stripped threads or a deformed nut, the lock nut should be replaced. Regular inspections can help identify issues early, preventing more significant problems down the line 3.

Maintenance Tips

To ensure the longevity and effectiveness of the Cummins 3285627 Lock Nut, regular maintenance checks are recommended. Inspect the lock nuts during routine service intervals to ensure they remain securely fastened. Look for signs of wear or damage, and replace any lock nuts that show signs of deterioration. Keeping the mating threads clean and free of debris will also help maintain the integrity of the fastening system 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products, including engines, powertrain components, and aftermarket parts, designed to meet the demanding needs of commercial transportation.

Role of Part 3285627 Lock Nut in Engine Systems

The part 3285627 Lock Nut is integral to the secure assembly and operation of various engine components. It ensures that connections remain tight and stable under the dynamic conditions of engine operation.

Accessories and Electric Starting Aid

In the context of accessories and electric starting aids, the Lock Nut is used to secure electrical connections and mounting points. This ensures that the electric starting aid functions reliably, providing consistent performance during engine start-up.

Coolant Heater Starting Arrangement

For the coolant heater starting arrangement, the Lock Nut plays a role in securing the heater elements and plumbing connections. This ensures that the coolant heater system operates efficiently, providing the necessary warmth to the engine components for easier starting in cold conditions.

Turbocharger and Battery

In turbocharger applications, the Lock Nut is employed to secure the turbocharger to the engine and exhaust manifold. This ensures that the turbocharger operates within its designed parameters, enhancing engine performance. Similarly, in battery installations, the Lock Nut secures the battery terminals and mounting brackets, ensuring a stable and reliable electrical connection.

Breather Assembly and Charge Air Cooler

The breather assembly and charge air cooler rely on the Lock Nut to maintain secure connections within their respective systems. For the breather assembly, this involves securing ventilation points, while for the charge air cooler, it ensures that the cooler remains firmly attached to the engine, promoting efficient air cooling.

Cleaner, Air Connection, and Air Intake

In air cleaner and air intake systems, the Lock Nut is used to secure connections between the air cleaner, air intake components, and the engine. This ensures that the air flow into the engine is unobstructed and that the air cleaner effectively filters incoming air.

Cooler, Fuel, and Exhaust Manifold

For fuel system components such as the fuel filter and fuel lines, the Lock Nut ensures that connections are leak-free and secure. In the exhaust manifold, it secures the manifold to the engine and other exhaust components, ensuring efficient exhaust flow and reducing the risk of leaks.

Harness, Main Extension, and Isolator

In electrical systems, the Lock Nut is used to secure wiring harnesses and main extensions, ensuring that electrical connections are stable and reliable. For vibration isolators, it secures the isolator to the engine and other components, reducing vibrations and enhancing engine longevity.

Muffler, Oil Tank, and Railcar Installation

The Lock Nut is vital in securing the muffler to the exhaust system, ensuring that exhaust gases are directed away from the engine efficiently. In railcar installations, it secures various components to the frame, ensuring stability and safety during transit. For the oil tank, it ensures that the tank is securely mounted, preventing leaks and ensuring proper oil circulation.

Plumbing, Air Cleaner, and Pump

In plumbing systems, particularly those involving the air cleaner and auxiliary pumps, the Lock Nut secures connections, ensuring that fluids are directed correctly and efficiently throughout the engine system.

Radiator, Shield, and Debris System

For the radiator and debris shield systems, the Lock Nut ensures that these components are securely attached to the engine, protecting it from external debris and ensuring efficient cooling.

Oil Replenishing, Water Inlet Tube, and Water Outlet Tube

In oil replenishing systems and water circulation systems (inlet and outlet tubes), the Lock Nut ensures that connections are secure, promoting efficient fluid circulation and maintaining engine health.

Wiring Harness

Finally, the Lock Nut is used throughout the wiring harness system to secure electrical connections, ensuring that the engine’s electrical systems operate reliably and efficiently.

Conclusion

The Cummins 3285627 Lock Nut is a critical component in the maintenance and operation of commercial trucks. Its design and features ensure secure fastening under dynamic conditions, enhancing the reliability and safety of truck assemblies. Proper installation, regular maintenance, and timely replacement of worn or damaged lock nuts are essential practices to ensure the continued performance and longevity of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.