This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3336565 Lock Nut is a specialized component designed for use in commercial truck maintenance and operation. This part plays a role in ensuring the secure fastening of various truck components, contributing to the overall reliability and safety of the vehicle.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners that prevent loosening due to vibration or rotation. They function by providing a secondary locking mechanism that complements standard nuts. In mechanical systems, lock nuts are important for maintaining the integrity of bolted connections. They operate on the principle of friction or deformation to resist movement, ensuring that components remain securely fastened under dynamic conditions 1.

Purpose of the Cummins 3336565 Lock Nut

The Cummins 3336565 Lock Nut is specifically designed to enhance the fastening security in truck applications. It is typically used in environments where vibrations and rotational forces are common, such as in the drivetrain, suspension, and engine components. By preventing nuts from loosening, it helps maintain the structural integrity and performance of critical truck systems 2.

Key Features

The Cummins 3336565 Lock Nut boasts several key features that enhance its performance and reliability. It is constructed from high-strength materials to withstand the rigors of commercial truck use. The design includes a nylon insert that deforms under torque, creating a locking action that resists vibration. Additionally, the lock nut features a prevailing torque mechanism that provides extra resistance to loosening 3.

Benefits of Using Lock Nuts in Truck Applications

Incorporating lock nuts like the Cummins 3336565 into truck assemblies offers several advantages. These include improved safety by ensuring that critical components remain securely fastened, reduced maintenance requirements due to the decreased likelihood of fastener loosening, and enhanced durability of the overall assembly. Lock nuts contribute to the longevity and reliability of truck operations.

Installation Guidelines

Proper installation of the Cummins 3336565 Lock Nut is vital for optimal performance. Begin by ensuring the mating threads are clean and free of debris. Apply the appropriate torque to the fastener, using a torque wrench to achieve the manufacturer’s specified torque value. It is important to avoid over-tightening, which can damage the lock mechanism. Follow the recommended sequence for tightening multiple fasteners to ensure even distribution of loads.

Troubleshooting Common Issues

Common issues with lock nuts include loosening, corrosion, and damage. To address loosening, verify that the correct torque was applied during installation and consider re-torqueing the fastener after a period of use. Corrosion can be mitigated by using lock nuts made from corrosion-resistant materials and applying an appropriate anti-seize compound. Damaged lock nuts should be replaced to maintain the integrity of the fastening system.

Maintenance Tips

Regular inspection and maintenance of lock nuts are necessary to ensure continued reliable operation. Inspect lock nuts during routine maintenance checks for signs of wear, corrosion, or loosening. Replace lock nuts that show signs of damage or excessive wear. Additionally, ensure that all fasteners are torqued to the manufacturer’s specifications during maintenance procedures to prevent issues.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s reputation is built on a commitment to excellence and customer satisfaction, making it a trusted source for truck components.

Lock Nut 3336565 Compatibility with Cummins Engines

The Lock Nut part number 3336565, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to ensuring the stability and reliability of the engine components it secures. Below is a detailed overview of its compatibility with specific engine models:

Cummins Engines Compatible with Lock Nut 3336565

- QSV81G

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

- QSZ90

Grouping of Compatible Engines

-

QSV Series: The QSV81G and QSV91G engines are part of the QSV series, known for their robust design and efficiency. The Lock Nut 3336565 ensures that the components within these engines remain securely fastened, preventing any loosening that could lead to operational issues.

-

QSW Series: The QSW/QSV82, QSW27, QSW36, and QSW73 engines are part of the QSW series, which is recognized for its versatility and adaptability across various applications. The Lock Nut 3336565 is important in maintaining the integrity of these engines by securing critical components.

-

QSZ Series: The QSZ90 engine, while part of a different series, also benefits from the use of the Lock Nut 3336565. This part ensures that the engine’s components are held firmly in place, contributing to the overall performance and longevity of the engine.

Each of these engines relies on the Lock Nut 3336565 to maintain the precision and reliability required for optimal operation. The compatibility of this part with these engines underscores its importance in the overall maintenance and performance of Cummins engines.

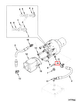

Role of Part 3336565 Lock Nut in Engine Systems

The Part 3336565 Lock Nut is instrumental in securing various components within engine systems, ensuring stability and preventing unwanted movement that could lead to inefficiencies or failures.

In the Actuator systems, the Lock Nut is used to firmly attach the actuator to its mounting points, ensuring that it operates within the designed parameters without shifting. This is particularly important in Actuators and Throttles Mounting where precise positioning is required for optimal performance.

For the Control Assembly Lever, the Lock Nut plays a role in maintaining the lever’s position relative to other components, which is essential for accurate control inputs. Similarly, in the Electric Assembly Governor, it ensures that electrical connections and mechanical linkages are held securely, contributing to consistent governor operation.

In the Engine Monitoring System, the Lock Nut is employed to secure sensors and other monitoring devices, ensuring they remain in the correct position to provide accurate readings.

Within the Filter, Oil Bypass system, it is used to keep the filter housing and bypass valve assembly intact, which is vital for maintaining oil cleanliness and pressure.

For the Fuel Pump A Bank Shaft and Fuel Pump B Bank Shaft, the Lock Nut is critical in securing the shaft in place, ensuring smooth and consistent fuel delivery. The Fuel Pump Drive Shaft also benefits from the Lock Nut, as it prevents any slippage or misalignment that could affect fuel pump performance.

In the Governor, Electronic and Governor Assembly Linkage, the Lock Nut ensures that all moving parts are correctly aligned and secured, which is essential for the governor to regulate engine speed effectively.

The Governor Assembly Shaft, Governor Control Linkage, Governor Counter Assembly Linkage, and Governor Linkage all rely on the Lock Nut to maintain their structural integrity and operational accuracy.

For the Linkage, Governor Control, the Lock Nut is used to secure the linkage components, ensuring that they transmit control signals accurately without any play or movement.

In the Lubricating Oil Pressure Assembly, the Lock Nut is employed to secure components that maintain oil pressure, which is vital for engine lubrication and cooling.

The Manifold and Throttle Assembly uses the Lock Nut to secure the throttle components, ensuring that air flow is controlled precisely.

In the Oil Bypass Assembly Filter and Oil Bypass Filter, the Lock Nut ensures that the filter elements are held in place, allowing for effective oil filtration.

Within the System, Engine Monitoring, the Lock Nut is used to secure various sensors and components, ensuring they function correctly and provide accurate data.

For the Throttle Assembly Shaft, Throttle Shaft, and Throttle Valve, the Lock Nut ensures that these components are held firmly in place, allowing for precise throttle control.

Finally, in the Valve, Throttle, the Lock Nut is used to secure the valve in its housing, ensuring it operates smoothly and effectively.

Conclusion

The Cummins 3336565 Lock Nut is a critical component in the maintenance and operation of commercial trucks. Its design and features ensure secure fastening of various truck components, contributing to the overall reliability and safety of the vehicle. Proper installation, regular maintenance, and understanding its role in engine systems are essential for optimal performance and longevity of truck operations.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Reif, Konrad, Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.