This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3336568 Regular Hexagon Nut, manufactured by Cummins, is a component used in the maintenance and operation of commercial trucks. Cummins, a well-established name in the automotive industry, produces this nut to meet the demanding requirements of heavy-duty applications. This part is integral to ensuring the secure fastening of various components within commercial trucks, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Regular Hexagon Nuts

A regular hexagon nut is a type of fastener characterized by its six-sided shape. This design allows for efficient tightening and loosening using standard hexagonal socket wrenches. The hexagonal shape provides a greater contact area compared to other shapes, which enhances the nut’s resistance to rounding off during use. This feature is particularly beneficial in high-torque applications, where the integrity of the fastening is paramount 1.

Purpose of the 3336568 Regular Hexagon Nut in Truck Operation

The 3336568 Regular Hexagon Nut plays a role in the assembly and maintenance of commercial trucks by securing various components. It is commonly used in applications where robust fastening is required, such as in the attachment of engine components, chassis parts, and other critical assemblies. Its design ensures that these components remain firmly in place, even under the strenuous conditions encountered in commercial truck operations 2.

Key Features of the 3336568 Regular Hexagon Nut

The 3336568 Regular Hexagon Nut is distinguished by several key features. It is typically made from high-strength materials to withstand the rigors of heavy-duty use. The thread type is designed to provide a secure fit, and the nut may feature special coatings or treatments to enhance its durability and resistance to corrosion. These characteristics make it suitable for the demanding environments encountered in commercial trucking 3.

Benefits of Using the 3336568 Regular Hexagon Nut

Using the 3336568 Regular Hexagon Nut in truck applications offers several advantages. Its durable construction ensures long-term reliability, while its resistance to vibration helps maintain secure fastenings over time. The hexagonal shape allows for easy installation and removal using standard tools, which simplifies maintenance procedures. Additionally, its corrosion-resistant properties contribute to extended service life, even in harsh operating conditions.

Installation Guidelines

Proper installation of the 3336568 Regular Hexagon Nut is vital to ensure secure fastening. It should be installed using the appropriate torque specifications provided by the manufacturer to achieve the correct tension. Best practices include cleaning the mating surfaces before installation to prevent contamination, which could compromise the fastening. Using a torque wrench ensures that the nut is tightened to the specified torque, avoiding over-tightening or under-tightening.

Troubleshooting Common Issues

Common issues with regular hexagon nuts include loosening due to vibration and corrosion. To address loosening, it may be necessary to re-torque the nut or apply a thread locker to enhance its resistance to vibration. Corrosion can be mitigated by ensuring that the nut and mating surfaces are clean and dry before installation, and by applying a corrosion-resistant coating if necessary. Regular inspections can help identify and address these issues promptly.

Maintenance Tips

Regular inspection and maintenance of the 3336568 Regular Hexagon Nut are recommended to prolong its service life and ensure reliable performance. This includes checking for signs of corrosion, ensuring that the nut remains securely fastened, and reapplying any protective coatings as needed. Keeping detailed maintenance records can also aid in tracking the condition of the nuts and scheduling replacements before failure occurs.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and transportation markets worldwide. The company is committed to providing reliable and efficient solutions that meet the needs of its customers, backed by a reputation for excellence in the automotive industry.

Cummins Regular Hexagon Nut 3336568 Compatibility with Engine Models

The Cummins Regular Hexagon Nut part number 3336568 is designed to fit seamlessly with a variety of engine models. This part is integral to the assembly and maintenance of several engine types, ensuring reliable performance and durability.

QSV81G and QSV91G Engines

The Regular Hexagon Nut 3336568 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and efficiency, and the nut plays a role in maintaining the integrity of the engine’s components.

QSW/QSV82 and QSW27 Engines

For the QSW/QSV82 and QSW27 engines, the part 3336568 is essential for securing various parts within the engine assembly. Its precision engineering ensures that the engine operates smoothly and efficiently.

QSW36 and QSW73 Engines

The QSW36 and QSW73 engines also benefit from the use of the Regular Hexagon Nut 3336568. This part is critical in maintaining the structural integrity of these engines, ensuring that all components are securely fastened.

QSZ90 Engine

Lastly, the QSZ90 engine incorporates the Regular Hexagon Nut 3336568 in its design. This part is vital for the proper functioning of the engine, providing the necessary support and stability required for optimal performance.

Role of Part 3336568 Regular Hexagon Nut in Engine Systems

The Part 3336568 Regular Hexagon Nut is a fundamental component in securing various engine systems and ensuring their reliable operation. Its application spans across multiple subsystems, contributing to the overall integrity and functionality of the engine.

Securing Accessories and Wiring

In the engine compartment, the Regular Hexagon Nut is employed to fasten accessories and wiring harnesses. This ensures that accessories remain firmly in place, minimizing the risk of disconnection or damage during engine operation. For wiring, it secures connections, reducing the likelihood of electrical faults that could arise from loose or frayed wires.

Actuator and Air Inlet Sub-Assembly

The actuator, which controls various engine functions, often requires precise mounting. The Regular Hexagon Nut plays a role in this by providing a stable attachment point, ensuring the actuator operates within specified parameters. Similarly, in the air inlet sub-assembly, these nuts secure components that manage airflow into the engine, maintaining optimal performance and efficiency.

Air Starting Motor and Control Assembly Engine

For the air starting motor, the Regular Hexagon Nut is critical in attaching the motor to the engine frame. This secure attachment is essential for the motor’s function in starting the engine under various conditions. In the control assembly engine, these nuts help in mounting control units, ensuring they are correctly positioned for accurate engine management.

Current Support Module and Electronic Control Engine

In the current support module and electronic control engine, the Regular Hexagon Nut is used to fasten electronic components. This secure mounting is vital for the stability and reliability of electronic systems, which are increasingly integral to modern engine control and monitoring.

Exhaust Assembly Manifold and Fuel Pump Drive Shaft

The exhaust assembly manifold relies on the Regular Hexagon Nut to secure manifold components, ensuring a tight seal and efficient exhaust flow. For the fuel pump drive shaft, these nuts are used to attach the drive mechanism, crucial for the consistent delivery of fuel to the engine.

Governor Assembly Shaft and Ignition Box Sub-Assembly

In the governor assembly shaft, the Regular Hexagon Nut secures components that regulate engine speed, ensuring smooth and controlled operation. In the ignition box sub-assembly, these nuts are used to mount ignition components, critical for the engine’s starting and running processes.

Module Engine Control and Fuel Control

For the module engine control and fuel control, the Regular Hexagon Nut is essential in securing control modules. This ensures these modules are correctly installed, allowing for precise engine and fuel management.

Starting Assembly Motor and Throttle Assembly Shaft

In the starting assembly motor and throttle assembly shaft, these nuts are used to secure starting and throttle components. This is important for the reliable starting of the engine and the accurate control of air intake, respectively.

Engine Coolant Vent and Oil Level Gauge

Finally, in the engine coolant vent and oil level gauge, the Regular Hexagon Nut is used to secure these components. This ensures the proper functioning of the cooling system and accurate monitoring of oil levels, both of which are essential for engine health and performance.

Conclusion

The 3336568 Regular Hexagon Nut is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its robust design, resistance to corrosion, and ease of installation make it an essential part for ensuring the secure fastening of engine components and accessories. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the performance and longevity of this Cummins part.

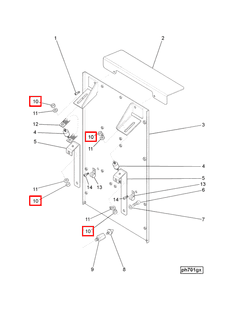

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.