This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

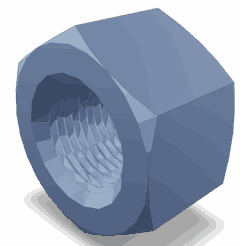

The Cummins 3336571 Lock Nut is a specialized component designed for use in commercial trucks. It serves to maintain secure fastenings, which is vital for the safe and efficient operation of these vehicles. This part is integral to ensuring that critical components remain firmly in place under various operating conditions, thereby contributing to the overall reliability and performance of commercial trucks.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners designed to prevent loosening due to vibration and other dynamic forces. They function by providing additional resistance to rotational movement, which can occur in applications where standard nuts might become loose over time. Lock nuts are commonly used in various mechanical systems to ensure that bolts and other threaded fasteners remain securely tightened. The principle behind lock nuts involves the use of a locking mechanism, such as a nylon insert or deformed threads, which creates friction and prevents the nut from unscrewing 1.

Purpose of the Cummins 3336571 Lock Nut

The Cummins 3336571 Lock Nut plays a specific role in the operation of commercial trucks by ensuring the integrity of critical fastenings. It is designed to withstand the rigors of heavy-duty applications, where vibrations and dynamic loads are common. By securely holding components in place, this lock nut helps maintain the structural integrity and performance of the truck’s systems, contributing to safer and more reliable operation.

Key Features

The Cummins 3336571 Lock Nut is characterized by several distinctive features that enhance its performance and reliability. Its design includes elements such as a nylon insert or deformed threads, which provide the necessary locking mechanism to prevent loosening. The material composition of the lock nut is chosen for its durability and resistance to corrosion, ensuring long-term performance in demanding environments. Additionally, the lock nut may feature a unique shape or threading pattern that further improves its locking capabilities 2.

Benefits

Using the Cummins 3336571 Lock Nut offers several advantages. Improved safety is one of the primary benefits, as secure fastenings reduce the risk of component failure during operation. Enhanced durability is another significant advantage, as the lock nut’s design and material composition contribute to its longevity. Reduced maintenance requirements are also a notable benefit, as the lock nut’s reliable performance minimizes the need for frequent inspections and replacements. These advantages collectively contribute to overall truck performance and longevity 3.

Installation Guidelines

Proper installation of the Cummins 3336571 Lock Nut is crucial for ensuring optimal performance and longevity. The following steps outline the installation process:

- Ensure the threaded surface is clean and free of debris.

- Align the lock nut with the corresponding bolt or threaded fastener.

- Tighten the lock nut to the specified torque using a torque wrench. Refer to the manufacturer’s guidelines for the exact torque specifications.

- Verify that the lock nut is securely in place and that there is no excessive movement.

Troubleshooting and Maintenance

Common issues associated with lock nuts include loosening due to inadequate torque or environmental factors. To identify these issues, regularly inspect the lock nuts for signs of movement or wear. Routine maintenance practices, such as periodic tightening and inspection, can help prolong the life of the Cummins 3336571 Lock Nut and ensure continued reliable performance. Additionally, replacing lock nuts that show signs of significant wear or damage is recommended to maintain system integrity.

Compatibility and Application

The Cummins 3336571 Lock Nut is typically used in various applications within commercial truck systems. It is compatible with a range of components and systems, ensuring versatile use across different truck models and configurations. When selecting lock nuts for specific applications, it is important to consider factors such as thread size, material compatibility, and environmental conditions to ensure optimal performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and quality in the production of automotive components. The company is committed to delivering reliable and high-performance parts that meet the demanding requirements of commercial trucking. Cummins’ dedication to quality and innovation is evident in its wide range of products, including the Cummins 3336571 Lock Nut.

Lock Nut 3336571 Compatibility with Cummins Engines

The Lock Nut part number 3336571, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is integral in ensuring the stability and security of various engine components, providing a reliable locking mechanism that prevents unwanted movement or loosening.

QSK45 CM500 and QSK60 CM500 Engines

The Lock Nut 3336571 is specifically engineered to fit the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The lock nut ensures that critical components remain securely fastened, enhancing the operational efficiency and longevity of these engines.

QSK60 CM850 MCRS and QSK78 CM500 Engines

For the QSK60 CM850 MCRS and QSK78 CM500 engines, the Lock Nut 3336571 plays a crucial role in maintaining the integrity of the engine’s assembly. These engines are designed for demanding applications, and the lock nut’s secure fitment is essential for maintaining operational safety and performance.

QSV91G, QSW/QSV82, QSW27, QSW36, QSW73, and QSZ90 Engines

The Lock Nut 3336571 is also compatible with the QSV91G, QSW/QSV82, QSW27, QSW36, QSW73, and QSZ90 engines. These engines, while differing in specifications and applications, all benefit from the lock nut’s ability to provide a dependable locking solution. Whether used in marine, industrial, or power generation applications, this part ensures that components remain tightly secured, contributing to the overall reliability and efficiency of the engines.

By ensuring a secure fitment across these diverse engine models, the Lock Nut 3336571 underscores Cummins’ commitment to providing high-quality, reliable components that meet the rigorous demands of various industrial and marine applications.

Role of Part 3336571 Lock Nut in Engine Systems

The 3336571 Lock Nut is a vital component in securing various parts within engine systems, ensuring stability and preventing unwanted movement that could lead to inefficiencies or failures.

In the Control Linkage Assembly Lever and Control Linkage Lever, the lock nut is used to secure the linkage to the lever, maintaining the precise alignment necessary for accurate control signals. This is particularly important in systems where the linkage is subject to dynamic forces.

Within the Crankcase Assembly Breather, the lock nut ensures that the breather components are tightly secured, preventing oil leaks and maintaining the integrity of the crankcase ventilation system.

For the Engine Assembly Piston, the lock nut is utilized in securing components such as the Piston Cooling Assembly Nozzle, ensuring that the nozzle remains fixed in place to provide consistent cooling to the piston, which is vital for engine longevity and performance.

In the Exhaust Assembly Manifold, the lock nut plays a role in securing manifold components, ensuring a tight seal that prevents exhaust leaks and maintains efficient exhaust flow.

The Governor system, which includes components like the Governor Assembly Linkage, Governor Assembly Shaft, Governor Control Linkage, Governor Counter Assembly Linkage, and Governor Linkage, relies on the lock nut to secure these parts, ensuring that the governor functions correctly to regulate engine speed.

In Hydraulic systems, particularly within the Hydraulic Assembly Governor, the lock nut is critical for securing hydraulic components, ensuring that there are no leaks and that the system operates under the correct pressures.

The Manifold Exhaust system also benefits from the use of lock nuts to secure various components, ensuring that the exhaust system remains intact and functions efficiently.

For Mounting Alternator applications, the lock nut is used to secure the alternator to the engine, ensuring that it remains in the correct position and operates efficiently.

In the Oil Assembly Pan and Pan Oil, the lock nut is essential for securing the oil pan to the engine, preventing oil leaks and ensuring that the oil system remains sealed.

Lastly, in the Throttle Assembly Shaft, the lock nut is used to secure the throttle components, ensuring that the throttle operates smoothly and accurately, which is essential for engine control and performance.

Conclusion

The Cummins 3336571 Lock Nut is a critical component in the maintenance and operation of commercial trucks and various Cummins engines. Its design and features ensure secure fastenings, contributing to the safety, reliability, and performance of these systems. Proper installation, regular maintenance, and understanding its role in different engine components are essential for maximizing the benefits of this part.

-

Joseph A Bell, Modern Diesel Technology Electricity Electronics, Delmar Cengage Learning, 2014.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.