This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Nut 3420724, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. Cummins is recognized for its commitment to producing high-quality components that enhance vehicle performance and reliability. The 3420724 nut is significant in maintaining the structural integrity and operational efficiency of trucks, particularly under demanding conditions 1.

Basic Concepts of Fracture Resistant Nuts

Fracture resistant nuts are designed to withstand high stress and prevent failures in mechanical systems. They are commonly used in applications where traditional nuts might fail due to fatigue, corrosion, or excessive load. These nuts function by distributing stress more evenly and resisting the initiation and propagation of cracks, thereby enhancing the longevity and reliability of the components they secure 2.

Purpose of the 3420724 Fracture Resistant Nut

The 3420724 Fracture Resistant Nut plays a specific role in the operation of commercial trucks. It is applied in areas where high stress and dynamic loads are common, such as in the fastening of critical components like engine mounts, transmission housings, and chassis parts. By providing a secure and durable connection, this nut helps maintain the structural integrity of the truck, ensuring safe and reliable performance 3.

Key Features

The 3420724 Fracture Resistant Nut is characterized by several primary features that enhance its performance. It is made from a high-strength alloy, which provides superior resistance to fracture under stress. The nut’s design includes specific threading and geometry that optimize load distribution and reduce the risk of failure. Additionally, unique manufacturing processes, such as heat treatment and precision machining, are employed to ensure consistent quality and performance.

Benefits

Using the 3420724 Fracture Resistant Nut offers several advantages. Its increased durability and reliability in high-stress environments contribute to the overall performance and safety of the truck. Additionally, the nut’s design can lead to potential cost savings over time due to reduced maintenance needs and lower risk of component failure.

Installation Considerations

Proper installation of the 3420724 Fracture Resistant Nut is crucial for optimal performance. Guidelines recommend adhering to specific torque specifications to ensure the nut is tightened to the correct level without over-tightening, which could lead to damage. Compatibility with other components should be verified to ensure a secure fit. Best practices include using the appropriate tools and following manufacturer recommendations to achieve the best results.

Troubleshooting and Maintenance

Common issues with fracture resistant nuts may include loosening over time or damage due to environmental factors. Regular inspections can help identify potential problems early. Maintenance practices such as periodic re-torqueing and protecting the nut from corrosion can prolong its service life. Addressing issues promptly ensures continued reliability and performance.

Comparative Analysis

When compared to standard nuts, the 3420724 Fracture Resistant Nut offers enhanced performance and durability. Its design and material composition provide greater resistance to fracture, making it suitable for applications where standard nuts may not suffice. The differences in performance and application scenarios highlight the advantages of using fracture resistant nuts in critical areas of commercial trucks.

Real-World Applications

The 3420724 Fracture Resistant Nut is utilized in various commercial truck models and configurations. Its versatility and effectiveness are demonstrated in applications ranging from heavy-duty hauling to long-haul transportation. The nut’s ability to withstand high stress and dynamic loads makes it a valuable component in ensuring the reliability and safety of commercial trucks.

Manufacturer Overview - Cummins

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for its commitment to quality and innovation, Cummins produces a wide range of automotive components that enhance vehicle performance and reliability. The company’s reputation is built on a foundation of excellence, customer satisfaction, and continuous improvement in manufacturing processes and product design.

Compatibility with Cummins Engines

The Fracture Resistant Nut 3420724 is designed to fit seamlessly with a range of Cummins engines. This part is crucial for ensuring the integrity and longevity of the engine’s components, particularly in high-stress environments.

QSV81G and QSV91G Engines

The Fracture Resistant Nut 3420724 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and are often used in heavy-duty applications. The nut’s design helps prevent fractures under high loads, ensuring the engine’s components remain securely fastened.

QSV91-G4 CM558/CM700 V102 Engines

For the QSV91-G4 CM558/CM700 V102 engines, the 3420724 nut provides critical support. These engines are part of the Cummins G-Series, which are designed for durability and efficiency. The nut’s fracture-resistant properties are essential for maintaining the structural integrity of these engines.

QSW/QSV82, QSW27, QSW36, and QSW73 Engines

The 3420724 nut also fits the QSW/QSV82, QSW27, QSW36, and QSW73 engines. These engines are part of the Cummins QSW Series, known for their versatility and reliability. The fracture-resistant nut ensures that these engines can withstand the rigors of continuous operation without compromising on safety or performance.

Grouping by Application

When considering the application of the 3420724 nut, it is important to note that it is designed to fit a variety of Cummins engines, whether they are part of the G-Series or the QSW Series. This versatility makes it a valuable component for maintaining the structural integrity of these engines across different models and applications.

Role of Part 3420724 Fracture Resistant Nut in Engine Systems

The Part 3420724 Fracture Resistant Nut is integral to the secure assembly and operation of various engine components. Its application ensures that connections remain intact under high stress and dynamic conditions, contributing to the overall reliability and performance of the engine system.

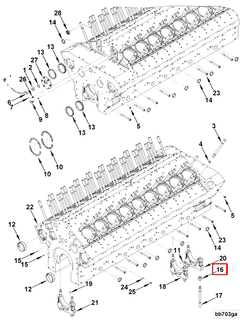

Assembly Head Cylinder

In the Assembly Head Cylinder, the Fracture Resistant Nut is used to fasten the cylinder head to the cylinder block. This secure attachment is vital for maintaining the integrity of the combustion chamber and ensuring proper sealing.

Camshaft and Camshaft Gear

For the Camshaft and Camshaft Gear, the nut is employed in the camshaft mounting process. It ensures that the camshaft remains precisely positioned, which is essential for the accurate timing of valve operations.

Cylinder Assembly Block and Cylinder Assembly Head

In the Cylinder Assembly Block and Cylinder Assembly Head, the nut plays a role in securing various components, ensuring that the assembly remains stable during engine operation. This stability is important for maintaining the structural integrity of the engine.

Cylinder Block and Cylinder Block Kit

Within the Cylinder Block and Cylinder Block Kit, the Fracture Resistant Nut is used to secure critical components, such as the main bearings and other mounting points. This ensures that the cylinder block can withstand the forces generated during engine operation.

Cylinder Head

The Cylinder Head relies on the nut for secure attachment to the cylinder block. This connection is essential for maintaining the seal between the head and block, which is critical for combustion efficiency.

Engine Oil Cooler and Oil Assembly Cooler

In the Engine Oil Cooler and Oil Assembly Cooler, the nut is used to secure the cooler to the engine block or other mounting points. This ensures that the cooler remains in place and functions effectively to regulate oil temperature.

Head Cylinder Assembly and Head Cylinder Mounting

For the Head Cylinder Assembly and Head Cylinder Mounting, the nut is crucial for securing the head to the block. This ensures a proper seal and maintains the structural integrity of the engine.

Head Gas Cylinder Assembly

In the Head Gas Cylinder Assembly, the nut is used to secure gas passages and other critical components, ensuring that the assembly functions correctly and maintains the desired performance levels.

Idler Gear

The Idler Gear system utilizes the Fracture Resistant Nut to secure the gear in place. This ensures that the gear operates smoothly and maintains the proper timing for engine components.

Module Assembly Gas

For the Module Assembly Gas, the nut is used to secure gas modules and related components. This ensures that the gas system operates efficiently and maintains the desired performance levels.

Mounting Head Cylinder

In the Mounting Head Cylinder, the nut is essential for securing the cylinder head to the block. This ensures a stable and secure connection, which is vital for engine performance and reliability.

Performance Parts

Performance Parts often require the use of the Fracture Resistant Nut to ensure that high-stress components remain securely fastened. This is particularly important in high-performance engines where components are subjected to greater forces.

Prechamber Bits

For Prechamber Bits, the nut is used to secure these components in place. This ensures that the prechamber operates correctly, contributing to improved combustion efficiency.

QSV and D67

In systems like the QSV and D67, the Fracture Resistant Nut is used to secure various components, ensuring that the system operates reliably under high-stress conditions. This is particularly important in applications where precision and reliability are paramount.

Conclusion

The 3420724 Fracture Resistant Nut by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and material composition provide enhanced durability and reliability, making it suitable for high-stress applications. Proper installation and maintenance are essential for optimal performance, ensuring the continued safety and efficiency of the vehicle.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.