This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

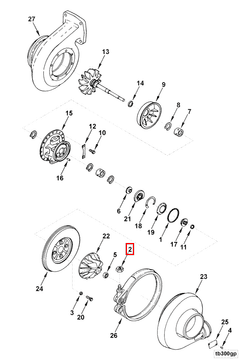

The Cummins 3519471 Lock Nut is a specialized fastener designed for use in heavy-duty truck applications. Its purpose is to provide secure fastening of components, ensuring stability and safety under demanding operational conditions. This part is integral to maintaining the integrity of various truck systems, contributing to overall vehicle performance and longevity.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners designed to resist loosening caused by vibration and dynamic forces. They function by creating a locking mechanism that prevents the nut from unscrewing once it has been tightened. This is achieved through various designs, such as nylon inserts, deformed threads, or prevailing torque features 1. The necessity of lock nuts in mechanical systems cannot be overstated, as they play a vital role in ensuring that fasteners remain securely in place, thereby maintaining the structural integrity and safety of the assembly.

Purpose of the Cummins 3519471 Lock Nut

The Cummins 3519471 Lock Nut is specifically engineered to address the unique challenges posed by heavy-duty truck environments. It plays a role in the secure fastening of components, which is crucial for the stability and safety of the vehicle. By preventing fasteners from loosening due to vibrations and other dynamic forces, this lock nut helps maintain the integrity of critical truck systems, ensuring reliable performance over time.

Key Features

The Cummins 3519471 Lock Nut boasts several key features that enhance its performance and reliability. It is constructed from high-quality materials, ensuring durability under harsh conditions. The design incorporates elements that strengthen its locking mechanism, such as a nylon insert or deformed threads, providing a prevailing torque that resists loosening. Additionally, this lock nut may feature unique attributes that set it apart from standard nuts, such as enhanced corrosion resistance or specialized thread patterns for improved grip.

Benefits

Using the Cummins 3519471 Lock Nut offers several benefits. It provides improved fastening security, ensuring that components remain tightly connected even under severe vibrations and dynamic loads. Its durable construction allows it to withstand the rigors of heavy-duty truck operations, maintaining tight connections over time. Reliability is another significant advantage, as this lock nut is designed to perform consistently in demanding environments, reducing the need for frequent maintenance and replacements.

Installation Guidelines

Proper installation of the Cummins 3519471 Lock Nut is crucial for optimal performance. Follow these step-by-step instructions:

- Ensure the mating threads are clean and free of debris.

- Align the lock nut with the corresponding fastener.

- Tighten the lock nut to the specified torque using a torque wrench. Refer to the manufacturer’s guidelines for the exact torque specifications.

- Double-check the tightness to confirm that the lock nut is securely in place.

- Perform a final inspection to ensure there are no signs of damage or improper installation.

Troubleshooting and Maintenance

Common issues with lock nuts include loosening over time, corrosion, and damage from improper installation. To troubleshoot these problems:

- Regularly inspect lock nuts for signs of loosening and re-torque as necessary.

- Clean and protect lock nuts from corrosion by applying appropriate coatings or treatments.

- Replace any damaged lock nuts promptly to maintain system integrity.

Periodic checks and re-torquing are recommended to ensure the longevity and effectiveness of the Cummins 3519471 Lock Nut.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation, providing reliable and efficient solutions for the automotive and heavy-duty truck industries 2. The company’s dedication to excellence is evident in its comprehensive product range and ongoing efforts to advance technology and improve performance.

Compatibility of Lock Nut 3519471 with Cummins Engines

The Lock Nut part number 3519471, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for securing components in place, ensuring the integrity and reliability of the engine’s operation.

N14 CELECT and N14 CELECT PLUS Engines

The Lock Nut 3519471 is compatible with both the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The lock nut ensures that the components remain tightly secured, preventing any loosening that could lead to engine failure.

N14 MECHANICAL Engine

Similarly, the N14 MECHANICAL engine also benefits from the use of the Lock Nut 3519471. This engine variant is favored for its mechanical simplicity and durability. The lock nut plays a crucial role in maintaining the mechanical integrity of the engine by keeping various parts firmly in place.

NH/NT 855 Engine

The NH/NT 855 engine is another model that can utilize the Lock Nut 3519471. This engine is designed for versatility and performance, making it suitable for a range of applications. The lock nut ensures that the engine’s components are securely fastened, contributing to the overall reliability and longevity of the engine.

QSK19G and QSK38 CM850 MCRS Engines

The Lock Nut 3519471 is also compatible with the QSK19G and QSK38 CM850 MCRS engines. These engines are known for their high power output and efficiency. The lock nut is essential in these engines to maintain the tight fit of various components, ensuring optimal performance and preventing any potential issues due to loose parts.

V28 and V903 Engines

For the V28 and V903 engines, the Lock Nut 3519471 is a critical component. These engines are designed for heavy-duty applications and require reliable fastening solutions to maintain their structural integrity. The lock nut ensures that all parts are securely held in place, contributing to the engine’s overall performance and durability.

VTA903 CM2250 V105 Engine

Lastly, the Lock Nut 3519471 is also suitable for the VTA903 CM2250 V105 engine. This engine is engineered for high performance and reliability, making it ideal for demanding applications. The lock nut ensures that all components are tightly secured, preventing any potential issues that could arise from loose parts.

Role of Part 3519471 Lock Nut in Engine Systems

The part 3519471 Lock Nut is an essential component in securing various elements within engine systems, ensuring stability and preventing unwanted movement or loosening of critical parts. Here’s how it integrates with the provided components:

Turbocharger Systems

In the 49 State 444 Turbocharger and 50 State 444 Turbocharger, the Lock Nut is used to secure the turbocharger to the engine block or exhaust manifold. This ensures that the turbocharger remains firmly in place, even under high-stress conditions, maintaining optimal performance and efficiency.

For the EBM: Turbocharger and Heat60 Turbocharger, the Lock Nut plays a similar role. It secures the turbocharger components, such as the turbine housing to the compressor housing, ensuring that there is no misalignment or movement that could affect the turbocharger’s performance.

Core Assemblies

In various Core Assemblies like the Core Assembly Heat3B, Core Assembly Heat4B, Core Assembly Heat4C, and Core Assembly Heat60, the Lock Nut is utilized to fasten core components together. This includes securing the core to the engine block and ensuring that all internal components remain aligned and stable during operation.

The Core Assembly HT3B (DCM) also benefits from the Lock Nut, which helps in maintaining the integrity of the assembly by preventing any shifting or loosening of parts.

Camshaft and Related Components

The Lock Nut is instrumental in the Camshaft system, particularly in securing the Cam Follower Shaft Support. This ensures that the camshaft remains properly aligned with the engine’s valves, contributing to smooth and efficient valve operation.

Injector and Control Systems

In the EBM-Injector system, the Lock Nut is used to secure the injector to the engine block, ensuring that it remains in the correct position for precise fuel delivery. Similarly, in the Engine Brake Control system, the Lock Nut helps in fastening control components, ensuring reliable operation of the brake system.

Overhaul and Rebuild Kits

Within Overhaul Kits and Rebuild Kits, the Lock Nut is a common component used to reassemble engine parts. It ensures that all newly installed or repaired components are securely fastened, providing stability and reliability in the rebuilt engine.

Performance and Repair Kits

In Performance Parts and Turbocharger Parts Kits, the Lock Nut is used to secure high-performance components, ensuring they withstand the increased stress and demands placed on the engine. For the Heat60 Turbocharger Repair Kit, the Lock Nut is essential in reassembling and securing repaired turbocharger components.

Engine Piston Kit

In the Engine Piston Kit, the Lock Nut may be used to secure piston-related components, ensuring that they remain in place and function correctly within the engine cylinder.

HC3 and Turbocharger Core

For the HC3 and Turbocharger Core, the Lock Nut is vital in assembling and securing core components, ensuring that the turbocharger operates efficiently and reliably.

By understanding the role of the Lock Nut in these various engine systems, engineers and mechanics can appreciate its importance in maintaining the integrity and performance of the engine.

Conclusion

The Cummins 3519471 Lock Nut is a critical component in heavy-duty truck applications, ensuring the secure fastening of various engine components. Its design and features contribute to the stability, safety, and longevity of the vehicle. Proper installation and maintenance of this part are essential for optimal performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.