This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3531786 Standard Hexagonal Jam Nut, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a reputable manufacturer in the automotive industry, produces this jam nut to meet the demanding requirements of heavy-duty applications. This component is integral to the secure fastening of various truck components, ensuring reliable performance and durability in commercial vehicle operations.

Basic Concepts of Standard Hexagonal Jam Nuts

A standard hexagonal jam nut is a type of fastener characterized by its hexagonal shape, which allows for easy tightening and loosening using standard tools. In mechanical systems, jam nuts are commonly used in conjunction with other fasteners to provide additional security. They function by being tightened against another nut or threaded component, creating friction that prevents loosening due to vibration or other dynamic forces 1.

Purpose of the 3531786 Standard Hexagonal Jam Nut in Truck Operations

The 3531786 Standard Hexagonal Jam Nut plays a significant role in the operation and maintenance of commercial trucks. It is applied in various truck components where secure fastening is required to withstand the rigors of heavy-duty use. This includes applications in the engine, transmission, and chassis systems, where it helps maintain the integrity of critical connections and assemblies 2.

Key Features

The 3531786 Standard Hexagonal Jam Nut features a hexagonal shape that facilitates straightforward installation and removal using common hand tools. Its material composition is designed to offer robust performance under heavy-duty conditions, ensuring longevity and reliability. The design specifications of this jam nut enhance its functionality, providing a secure fastening solution that resists loosening over time 3.

Benefits

Using the 3531786 Standard Hexagonal Jam Nut offers several benefits. It provides improved fastening security, which is vital in applications where vibrations and dynamic loads are common. The ease of use, thanks to its hexagonal shape, allows for quick and efficient installation. Additionally, its durability under heavy-duty conditions ensures that it maintains performance over the long term, reducing the need for frequent replacements 4.

Installation Process

Proper installation of the 3531786 Standard Hexagonal Jam Nut involves several steps to ensure optimal performance. Begin by selecting the appropriate size and type of primary fastener. Apply the jam nut by tightening it against the primary fastener until the desired level of friction is achieved. Use a torque wrench to ensure consistent tightening force, avoiding over-tightening which can damage threads or components. Regularly inspect the installation to confirm that it remains secure.

Troubleshooting and Maintenance

Common issues with the 3531786 Standard Hexagonal Jam Nut may include loosening due to vibration or corrosion over time. To address these issues, regularly inspect the fastener for signs of wear or damage. If loosening is detected, re-tighten the jam nut to the specified torque settings. In cases of corrosion, clean the affected area and consider applying a corrosion-resistant coating to prevent further issues. Routine maintenance checks will help ensure the longevity and performance of the jam nut.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. Founded with a commitment to quality and innovation, Cummins has a long history of producing reliable automotive components. Their dedication to excellence is evident in the design and manufacturing of the 3531786 Standard Hexagonal Jam Nut, which reflects their ongoing efforts to meet the needs of commercial truck operators with durable, high-performance fasteners.

Application in Cummins Engines

The 3531786 Jam Nut is utilized across several Cummins engine models, including but not limited to:

- L10 GAS Engines

In the L10 GAS engines, the 3531786 Jam Nut is employed in various applications where it needs to provide a reliable locking mechanism. This is particularly important in high-stress environments where vibrations and operational forces can otherwise cause bolts to loosen. The use of this jam nut ensures that critical engine components remain securely fastened, contributing to the overall reliability and performance of the engine.

Role of Part 3531786 Standard Hexagonal Jam Nut in Engine Systems

The Part 3531786 Standard Hexagonal Jam Nut is integral to the assembly and maintenance of various engine components, ensuring secure fastening and reliable performance.

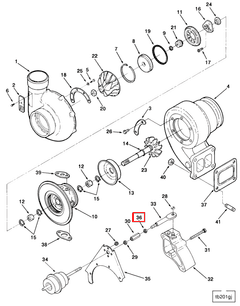

In an aftermarket turbocharger, this jam nut is often used to secure the turbine housing to the exhaust manifold, providing a tight seal that is essential for efficient turbo operation. It helps maintain the integrity of the exhaust flow, which is vital for the turbocharger’s performance.

When dealing with a gear repair kit, the jam nut plays a role in securing gear components, ensuring that they remain in place during operation. This is particularly important in high-stress environments where gear misalignment can lead to failure.

For performance parts, the jam nut is frequently employed to fasten critical components, such as sensor brackets or ancillary device mounts. Its hexagonal shape allows for precise torque application, which is necessary for maintaining the performance standards of high-output engines.

In a pre-set turbine housing kit, the jam nut is used to secure the housing to the engine block or manifold. This ensures that the turbine operates within its designed parameters, contributing to the overall efficiency and reliability of the turbocharger system.

The prechamber-set actuator kit often includes the jam nut to secure the actuator to the turbocharger. This is essential for maintaining the actuator’s position and ensuring that it can respond accurately to control signals, which is vital for precise turbo control.

In a turbocharger, the jam nut is used in various applications, such as securing the compressor cover or fastening the wastegate linkage. Its role in these applications is to provide a secure connection that can withstand the high pressures and temperatures associated with turbocharging.

For a turbocharger kit, the jam nut is a common component used to assemble various parts, ensuring that all connections are tight and secure. This is important for the kit’s overall performance and durability.

In a wastegate actuator kit, the jam nut is used to secure the actuator to the wastegate arm. This ensures that the actuator can effectively control the wastegate, which is essential for managing turbo boost levels and protecting the engine from over-boosting.

Finally, in a wastegate t/housing sub-assembly, the jam nut is used to secure the wastegate housing to the turbocharger. This is important for maintaining the wastegate’s position and ensuring that it can operate effectively to regulate exhaust flow and turbo boost.

Conclusion

The 3531786 Standard Hexagonal Jam Nut is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure fastening, durability, and reliable performance in heavy-duty applications. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Barton, David C, and John D Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.