This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

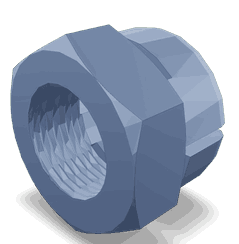

The Socket Head Cap Screw is a fundamental component in the maintenance and assembly of commercial trucks. Manufactured by Cummins, a leader in the commercial truck industry, the Socket Head Cap Screw part number 3590444 is designed for heavy-duty applications. This screw is integral to the reliable operation and maintenance of commercial trucks, ensuring secure fastening in various critical components.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a cylindrical head with an integrated hex socket. This design allows for efficient installation and removal using a hex key. Typically made from materials such as alloy steel or stainless steel, these screws offer high tensile strength and resistance to corrosion 1. The hex socket design provides a larger contact area compared to traditional hex bolts, reducing the risk of cam-out during tightening.

Purpose of the 3590444 Socket Head Cap Screw in Truck Operation

The 3590444 Socket Head Cap Screw plays a role in the assembly and maintenance of commercial trucks by providing secure fastening in various applications. It is commonly used in the attachment of engine components, chassis parts, and other critical assemblies where durability and reliability are paramount. Its design ensures that it can withstand the rigors of heavy-duty truck operation, maintaining secure connections under significant stress and vibration.

Key Features

The 3590444 Socket Head Cap Screw features a hex socket drive, which facilitates easy installation and removal using a hex key. This design enhances efficiency during maintenance procedures. The screw’s thread pitch is optimized to provide secure fastening, ensuring that components remain firmly attached under operational conditions. Additionally, the screw is crafted from high-quality materials to ensure durability and resistance to environmental factors.

Benefits

Socket Head Cap Screws offer several advantages in truck maintenance. Their corrosion-resistant properties make them suitable for use in various environmental conditions, reducing the need for frequent replacements. The high tensile strength of these screws ensures they can withstand significant loads, providing reliable fastening solutions. Compared to other fasteners, Socket Head Cap Screws offer ease of use and reduced installation time, contributing to efficient maintenance practices 2.

Installation and Usage Guidelines

Proper installation of the 3590444 Socket Head Cap Screw involves several steps to ensure secure fastening. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use a hex key to drive the screw into the pre-drilled hole, ensuring it is aligned correctly. Tighten the screw to the recommended torque specification to achieve the desired clamping force without over-tightening, which could damage the screw or the component. Regular checks should be performed to ensure the screw remains secure during operation.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws include loosening due to vibration or corrosion. Regular inspections should be conducted to identify any signs of wear or damage. If a screw appears loose, it should be re-tightened to the specified torque. In cases of significant corrosion or damage, replacement of the screw is recommended to maintain the integrity of the fastening. Proper maintenance practices, including regular inspections and timely replacements, will prolong the lifespan of the screws.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation among truck operators and maintenance professionals. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty truck applications. Cummins’ dedication to excellence ensures that their components, like the 3590444 Socket Head Cap Screw, deliver consistent performance and durability.

Socket Head Cap Screw 3590444 Compatibility with Cummins Engines

The Socket Head Cap Screw part number 3590444, manufactured by Cummins, is a critical component in various engine assemblies. This screw is designed to provide secure fastening in high-stress environments, ensuring the integrity and reliability of engine components. Here is a detailed overview of its compatibility with specific Cummins engines:

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

The QSK19 series engines benefit from the Socket Head Cap Screw 3590444 in various applications, including securing engine mounts, brackets, and other critical components. Its robust design ensures that these engines maintain their structural integrity under demanding conditions.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

In the QSK38 series, the 3590444 screw is used to fasten components that require high tensile strength and resistance to vibration. This ensures that the engine’s internal and external components remain securely fastened, contributing to the overall performance and longevity of the engine.

QSK45 and QSK50 Series

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

These engines utilize the 3590444 screw for fastening various parts, including those that are subject to high mechanical stress. The screw’s design provides the necessary strength and durability to maintain the structural integrity of these engines.

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

The QSK60 series engines also incorporate the 3590444 screw in their assemblies. This screw is used in applications where high reliability and resistance to loosening are critical, ensuring that the engine components remain securely fastened.

QSK78 and QSK95 Series

- QSK78 CM500

- QSK95 CM2350 K111

In these engines, the 3590444 screw is used to secure components that are exposed to significant mechanical stress and vibration. Its design ensures that these components remain tightly fastened, contributing to the engine’s overall performance and durability.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

The QST30 series engines utilize the 3590444 screw in various applications, including securing engine mounts and brackets. This screw’s design provides the necessary strength and durability to maintain the structural integrity of these engines.

QSV91 and QSW/QSV82 Series

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW36

These engines incorporate the 3590444 screw in their assemblies, particularly in applications where high reliability and resistance to loosening are critical. The screw’s design ensures that the engine components remain securely fastened, contributing to the engine’s overall performance and longevity.

Role of Part 3590444 Socket Head Cap Screw in Engine Systems

The 3590444 Socket Head Cap Screw is a versatile fastener utilized across various engine components to ensure secure and reliable connections. Its application spans multiple critical areas within engine systems, contributing to the overall performance and durability of the assembly.

Turbocharger Assemblies

In turbocharger and aftermarket turbocharger setups, the 3590444 Socket Head Cap Screw is employed to fasten the turbocharger to the engine block or manifold. This secure attachment is vital for maintaining the integrity of the turbocharger assembly, ensuring it operates efficiently under high-stress conditions. Additionally, in turbocharger kits, these screws are used to assemble individual components, such as the compressor and turbine housings, guaranteeing a tight and leak-free seal.

Fuel System Components

Within the fuel control module and integrated fuel system module service/repair kit, the 3590444 Socket Head Cap Screw plays a significant role. It is used to mount the fuel control module to the engine bay, providing a stable platform for the module to regulate fuel delivery. In the gear fuel pump kit, these screws secure the pump to the engine, ensuring consistent fuel pressure and flow. The secure attachment is essential for the reliable operation of the fuel system, directly impacting engine performance.

Camshaft and Gear Assemblies

For the camshaft and gear assembly, the 3590444 Socket Head Cap Screw is utilized to fasten various components, such as the camshaft to the cylinder head and the timing gears to the camshaft. This ensures precise timing and smooth operation of the valve train, which is fundamental for engine efficiency and power output.

Injectors and Performance Parts

In the installation of injectors, the 3590444 Socket Head Cap Screw is used to secure the injectors to the cylinder head, ensuring they are properly aligned and sealed. This is particularly important in high-performance engines where injector placement and sealing directly affect fuel atomization and combustion efficiency. Additionally, in performance parts, these screws are often used to attach aftermarket components, such as cold air intakes or exhaust manifolds, ensuring they are securely fastened and can withstand the increased stress of high-performance operation.

V Band Clamps

The 3590444 Socket Head Cap Screw is also integral in the application of V band clamps. These clamps are used to secure exhaust and intake components, and the screws ensure a tight and consistent seal. This is essential for maintaining the integrity of the exhaust and intake systems, preventing leaks that can reduce engine performance and efficiency.

Conclusion

The 3590444 Socket Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks and various engine systems. Its design ensures secure fastening in high-stress environments, contributing to the overall performance and durability of the assembly. Proper installation, regular maintenance, and timely replacement are essential to ensure the reliable operation of these components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.