This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3934685 Plug Nut is a component designed for use in commercial trucks. It serves a specific function in the maintenance and operation of these vehicles, ensuring the integrity of various connections within the truck’s systems. Understanding its purpose and significance is vital for maintaining the efficiency and reliability of commercial trucks.

Basic Concepts of Plug Nuts

A plug nut is a type of fastener used to seal and secure connections in mechanical systems. It operates by threading onto a corresponding male component, creating a tight seal that prevents leaks and secures the connection. In the context of a truck’s component setup, plug nuts are employed in various systems where fluid or gas transfer occurs, ensuring that these transfers are conducted without loss or contamination 1.

Purpose of the Cummins 3934685 Plug Nut

The Cummins 3934685 Plug Nut plays a role in sealing and securing connections within a truck’s system. It is specifically designed to fit into the truck’s component setup, providing a reliable seal that prevents leaks and ensures the integrity of the connection. This function is crucial for maintaining the efficiency of the truck’s systems, as any leak or loose connection can lead to performance issues or safety concerns 2.

Key Features

The Cummins 3934685 Plug Nut is characterized by several key features that enhance its performance and durability. It is made from materials that offer resistance to corrosion and wear, ensuring longevity even in harsh operating conditions. Its design includes threading that allows for a secure fit, and it may possess unique attributes that further improve its sealing capabilities and ease of installation 3.

Benefits of Using the Cummins 3934685 Plug Nut

Incorporating the Cummins 3934685 Plug Nut into truck maintenance offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and ensuring that connections remain secure under various operating conditions. Its durability means it can withstand the rigors of commercial truck use, and its design facilitates ease of installation, saving time during maintenance procedures.

Installation Process

Proper installation of the Cummins 3934685 Plug Nut involves several steps to ensure a secure and effective seal. Begin by cleaning the connection point to remove any debris or old sealant. Thread the plug nut onto the corresponding male component, ensuring it is aligned correctly. Tighten the plug nut to the manufacturer’s specified torque setting to achieve the proper seal without over-tightening, which could damage the threads or the component itself. It is also important to avoid common pitfalls such as cross-threading or using excessive force, which can compromise the integrity of the connection.

Troubleshooting Common Issues

Frequent problems associated with plug nuts include leaks or loose connections. These issues can often be traced back to improper installation or wear and tear over time. To address leaks, first, ensure the plug nut is correctly installed and tightened to the proper torque. If the problem persists, inspect the plug nut and the connection point for damage or wear that may require replacement. For loose connections, re-tighten the plug nut, ensuring it is not over-tightened, and check for any underlying issues that may be causing the connection to loosen.

Maintenance Tips

Regular maintenance of the Cummins 3934685 Plug Nut is key to ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear, corrosion, or damage. If any issues are detected, the plug nut should be replaced to prevent potential leaks or failures. Additionally, following the manufacturer’s guidelines for torque settings during installation and re-installation can help maintain the integrity of the seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is committed to quality and innovation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, ensuring reliability, efficiency, and performance. Cummins’ dedication to excellence is evident in its comprehensive approach to product development, customer service, and support, making it a trusted name in the industry.

Plug Nut 3934685 Compatibility with Cummins Engines

The Plug Nut part number 3934685, manufactured by Cummins, is a critical component in ensuring the integrity and functionality of various engine systems. This part is designed to fit seamlessly with several Cummins engine models, enhancing the overall performance and reliability of these engines.

L10 GAS

The Plug Nut 3934685 is compatible with the L10 GAS engine. This part plays a vital role in securing the plug within the engine, ensuring that there are no leaks or malfunctions that could compromise engine performance.

QSV81G and QSV91G

For the QSV81G and QSV91G engines, the Plug Nut 3934685 is an essential component that ensures the plug is securely fastened. This is crucial for maintaining the engine’s operational efficiency and preventing any potential issues that could arise from a loose or improperly secured plug.

QSV91-G4 CM558/CM700 V102

In the QSV91-G4 CM558/CM700 V102 engine, the Plug Nut 3934685 is designed to fit precisely, providing a secure connection for the plug. This ensures that the engine operates smoothly and reliably, with no risk of the plug becoming dislodged during operation.

The Plug Nut 3934685 is a versatile and essential component that is compatible with a range of Cummins engines, including the L10 GAS, QSV81G, QSV91G, and QSV91-G4 CM558/CM700 V102. Its design ensures that the plug is securely fastened, contributing to the overall performance and longevity of the engine.

Role of Part 3934685 Plug Nut in Engine Systems

The 3934685 Plug Nut is an essential component in securing and maintaining the integrity of various engine systems. It plays a significant role in the following components:

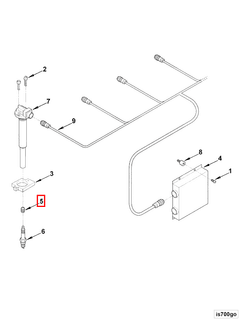

Ignition Coil Assemblies

- IGN Coil Assy SEM-M14 and IGN Coil Assy SEM-M18: The 3934685 Plug Nut is utilized to fasten the ignition coil assemblies to the engine block or cylinder head. This ensures a stable connection, which is vital for the consistent performance of the ignition system. Proper fastening prevents any movement that could lead to intermittent connections or failure of the ignition coils.

Spark Plug System

- Spark Plug and Spark Plug Kit: In the spark plug system, the 3934685 Plug Nut is employed to secure the spark plug wires or boots to the spark plugs. This connection is necessary to maintain a reliable electrical path from the ignition coil to the spark plug, ensuring efficient combustion within the engine cylinders. The Plug Nut helps to prevent any electrical arcing that could occur due to loose connections.

Ignition System

- The ignition system relies on the 3934685 Plug Nut to maintain the structural and electrical integrity of its components. By securing various connections within the system, the Plug Nut contributes to the overall reliability and performance of the engine’s ignition process. This includes ensuring that the high-voltage signals are transmitted effectively from the ignition coil to the spark plugs, facilitating timely and precise ignition of the air-fuel mixture.

Conclusion

The Cummins 3934685 Plug Nut is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its role in sealing and securing connections within various engine systems ensures the integrity and efficiency of these systems. Proper installation, regular maintenance, and understanding its compatibility with different engine models are essential for maximizing the performance and reliability of commercial trucks and engines.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.