This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5478960 Lock Nut is a component manufactured by Cummins, a well-established name in the commercial vehicle industry. This lock nut is specifically designed for use in commercial trucks, where it plays a significant role in ensuring the secure fastening of various components.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners that prevent loosening due to vibration or rotation. They function by creating a locking mechanism that holds the nut in place once it is tightened. This is achieved through various designs, such as nylon inserts, deformed threads, or prevailing torque features. Lock nuts are commonly used in applications where the integrity of the fastening is critical, such as in automotive, aerospace, and heavy machinery industries 1.

Purpose of the 5478960 Lock Nut in Truck Operations

The 5478960 Lock Nut is integral to the operation and maintenance of commercial trucks. It is used to secure components that are subject to significant vibration and rotational forces, such as wheel bearings, engine mounts, and other critical assemblies. By providing a reliable fastening solution, this Cummins part helps maintain the structural integrity and safety of the vehicle 2.

Key Features of the 5478960 Lock Nut

The 5478960 Lock Nut is designed with several features that enhance its performance in heavy-duty applications. It is constructed from high-strength materials to withstand the rigors of commercial truck operations. The lock nut incorporates a prevailing torque feature, which provides resistance to loosening without the need for additional locking mechanisms. This design ensures that the nut remains securely fastened under dynamic conditions 3.

Benefits of Using the 5478960 Lock Nut

The 5478960 Lock Nut offers several advantages for commercial truck applications. Its prevailing torque design provides enhanced security against loosening, which is particularly important in environments where vibrations are common. Additionally, the high-strength material used in its construction contributes to its durability and longevity, even in harsh operating conditions. This results in reduced maintenance requirements and increased safety for the vehicle and its occupants 4.

Installation Guidelines

To ensure optimal performance and safety, the 5478960 Lock Nut should be installed according to the following guidelines:

- Clean the threading on the fastener and the mating surface to remove any debris or corrosion.

- Apply a suitable thread lubricant to facilitate installation and prevent galling.

- Use a torque wrench to tighten the lock nut to the manufacturer’s specified torque setting. This ensures that the nut is properly secured without over-tightening, which could damage the threads or the component being fastened.

- After initial installation, periodically check the torque to ensure that the nut has not loosened over time 5.

Troubleshooting Common Issues

Common issues with lock nuts include loosening due to vibration or damage from over-tightening. To address these problems:

- Regularly inspect lock nuts for signs of loosening or wear.

- If a lock nut shows signs of loosening, re-tighten it to the specified torque setting. If it continues to loosen, consider replacing it with a new one.

- Avoid over-tightening, as this can strip the threads or damage the fastener. Always use a torque wrench to apply the correct amount of force 6.

Maintenance Tips

To prolong the service life of the 5478960 Lock Nut and ensure continued reliable performance:

- Conduct regular inspections during routine maintenance checks.

- Clean and lubricate the threads as needed to prevent corrosion and facilitate easy removal if necessary.

- Replace lock nuts that show signs of significant wear or damage to maintain the integrity of the fastening 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle industry. The company’s extensive product range and commitment to customer satisfaction make it a preferred choice for commercial truck operators and maintenance professionals 8.

Cummins Lock Nut 5478960 Compatibility

The Cummins Lock Nut part number 5478960 is a critical component designed to secure various parts within the engine assembly. This lock nut is compatible with a wide range of Cummins engines, ensuring a secure fit and reliable performance. Below is a detailed breakdown of the engines with which this lock nut is compatible:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM2150 SN

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

ISM Series Engines

- ISM CM570/870

- ISM CM876

ISX Series Engines

- ISX15 CM2250

K Series Engines

- K19

- K38

- K50

L Series Engines

- L8.9 CM2670 L134C

- L9 CM2670 L128B

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

This lock nut is engineered to meet the stringent requirements of Cummins engines, ensuring durability and reliability in various operating conditions. Its compatibility across multiple engine series highlights its versatility and importance in maintaining the integrity of the engine assembly 9.

Role of Part 5478960 Lock Nut in Engine Systems

Part 5478960 Lock Nut is integral to the secure assembly and operation of various engine components. It ensures that connections remain tight and stable under the demanding conditions of engine operation.

Turbocharger System

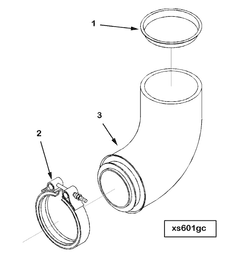

In the turbocharger system, the Lock Nut is used at the turbocharger connection and turbocharger exhaust connection. It secures the turbocharger to the exhaust manifold and the exhaust system, ensuring that there are no leaks in the high-pressure exhaust gases. This is essential for maintaining the efficiency and performance of the turbocharger.

Exhaust System

Within the exhaust system, the Lock Nut plays a significant role in several connections. At the exhaust outlet connection and the exhaust connection turbocharger, it ensures that the exhaust gases flow smoothly without any interruptions. It is also used in the exhaust elbow and exhaust clamp connections to maintain the integrity of the exhaust path.

Aftertreatment System

In the aftertreatment system, the Lock Nut is employed at the aftertreatment catalyst inlet and the doser fluid connection. This ensures that the doser fluid is accurately delivered to the catalyst, enhancing the efficiency of the aftertreatment process. It also secures the connections in the decomposition reactor, ensuring that the reactions occur under optimal conditions.

Engine Brake Kit

For the engine brake kit, the Lock Nut is utilized in the brake connection to ensure that the brake system functions correctly. This is vital for the safe and effective operation of the engine brake, especially under heavy load conditions.

Plumbing and Packaging

In the plumbing of engine accessories and the arrangement of shipping and product installation packages, the Lock Nut ensures that all components are securely fastened. This is important for the overall stability and reliability of the engine system during transportation and installation.

V-Band Clamp Connections

The Lock Nut is also crucial in V-band clamp connections, where it ensures that the clamps remain tightly secured. This is particularly important in high-vibration environments, where loose connections can lead to performance issues or even failures.

Overall, the Part 5478960 Lock Nut is a fundamental component in maintaining the structural integrity and operational efficiency of various engine systems 10.

Conclusion

The 5478960 Lock Nut is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design, featuring a prevailing torque mechanism and high-strength materials, ensures reliable fastening in demanding environments. Proper installation, regular maintenance, and timely replacement are essential to maximize the benefits of this part, contributing to the overall safety and efficiency of the vehicle.

-

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Cummins Inc. (n.d.). QSK60G (Single Turbocharger) Hot Start Fast Ramp Generator Set Applications. Bulletin Number 4388868, Operation and Maintenance Manual.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). QSK60G (Single Turbocharger) Hot Start Fast Ramp Generator Set Applications. Bulletin Number 4388868, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSK60G (Single Turbocharger) Hot Start Fast Ramp Generator Set Applications. Bulletin Number 4388868, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.