This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

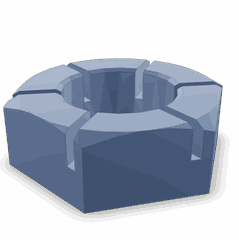

The Cummins 67532 Lock Nut is a specialized component designed for heavy-duty truck applications. It provides secure fastening in environments where standard nuts may not suffice due to vibration or dynamic forces. This part is significant in maintaining the integrity and safety of truck components, ensuring that critical parts remain securely fastened during operation.

Basic Concepts of Lock Nuts

Lock nuts are mechanical fasteners designed to resist loosening under vibration and dynamic loads. They function by creating additional friction between the nut and the threaded component, which prevents the nut from unscrewing. Lock nuts are commonly used in applications where standard nuts may loosen over time, leading to potential failure of the assembly. They are integral in ensuring the reliability and safety of mechanical systems 1.

Purpose of the Cummins 67532 Lock Nut

The Cummins 67532 Lock Nut provides a secure fastening solution in areas prone to vibration and dynamic stress. It is typically used in applications where the failure of a fastening could lead to significant operational issues or safety hazards. Its application areas include engine components, transmission systems, and chassis parts. The lock nut ensures that these critical components remain securely fastened, contributing to the overall reliability and performance of the truck.

Key Features

The Cummins 67532 Lock Nut is characterized by several key features that enhance its performance and reliability. It is constructed from high-strength materials, ensuring durability under harsh operating conditions. The design includes a nylon insert or deformed threads that create additional friction, preventing the nut from loosening. These features contribute to the lock nut’s ability to maintain secure fastenings in demanding environments 2.

Benefits

Using the Cummins 67532 Lock Nut offers several advantages. It provides improved security of fastenings, ensuring that critical components remain securely attached during operation. The lock nut’s resistance to vibration makes it suitable for use in dynamic environments, reducing the risk of fastening failure. Additionally, its durability in harsh operating conditions contributes to the longevity of the fastening, minimizing the need for frequent replacements.

Installation Guidelines

Proper installation of the Cummins 67532 Lock Nut is crucial for optimal performance and safety. To install, first, ensure the threaded component is clean and free of debris. Apply a small amount of thread locker if specified by the manufacturer. Then, using the appropriate tool, tighten the lock nut to the recommended torque specification. It is important to avoid over-tightening, as this can damage the threads or the lock nut itself. Regular inspection after installation is recommended to ensure the fastening remains secure 3.

Troubleshooting Common Issues

Typical problems that may arise with lock nuts include loosening or damage. If a lock nut appears loose, it should be re-tightened to the specified torque. If damage is observed, the lock nut should be replaced to ensure continued secure fastening. Regular maintenance and inspection can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To prolong the service life and ensure the continued reliable operation of the Cummins 67532 Lock Nut, regular inspection and maintenance are recommended. Inspect the lock nut and its fastening for signs of loosening or damage during routine maintenance checks. If any issues are identified, address them promptly to prevent further complications. Additionally, ensure that the lock nut is correctly installed and tightened according to the manufacturer’s specifications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Lock Nut 67532, manufactured by Cummins, is designed to fit seamlessly within the engine systems of the N14 G and N14 MECHANICAL engines.

For the N14 G engine, the Lock Nut 67532 is integral in maintaining the stability of several engine components. Its robust design ensures that it can withstand the operational stresses and vibrations inherent in this engine model, providing a reliable locking mechanism that prevents loosening over time.

Similarly, in the N14 MECHANICAL engine, the Lock Nut 67532 plays a pivotal role in securing various parts. The mechanical nature of this engine model necessitates a dependable locking solution, and the Lock Nut 67532 meets these requirements by offering a secure fit that enhances the overall integrity of the engine assembly.

In both engine types, the Lock Nut 67532 is engineered to interface with specific threads and fasteners, ensuring compatibility and ease of installation. Its precision-made design guarantees that it will function optimally within the specified engine environments, contributing to the longevity and performance of the engine systems.

Role of Part 67532 Lock Nut in Engine Systems

The Part 67532 Lock Nut is integral to the secure assembly and operation of various engine components. In the Assembly Fan Hub, it ensures that the fan hub remains firmly attached to the engine, preventing any unwanted movement that could lead to imbalance or failure.

Within the Assembly Lever and Assembly Shaft and Lever, the lock nut plays a significant role in maintaining the structural integrity of these components. It secures the lever and shaft in place, ensuring smooth and reliable operation of the engine’s moving parts.

In the Belt Tension Arrangement and Belt Tensioning Assembly, the lock nut is used to keep the tensioner in the correct position. This is vital for the proper functioning of the belt, which drives various engine accessories such as the alternator, water pump, and air conditioning compressor.

For the Belt Tensioning for Sea Water Pump, the lock nut ensures that the tensioner maintains the appropriate pressure on the belt, which is essential for the efficient operation of the sea water pump. This, in turn, ensures proper cooling of the engine.

In the Fan Bracket and Fan Hub Assembly, the lock nut secures the fan to the bracket and hub, ensuring that the fan operates efficiently to cool the engine.

The Jockey Pulley Assy. also benefits from the use of the lock nut, as it ensures that the pulley remains in the correct position, allowing for smooth belt operation.

In the context of the Rad. Cooling System and Radiator Cooling, the lock nut is used in various connections and attachments to ensure that all components are securely fastened, contributing to the overall efficiency and reliability of the cooling system.

Overall, the Part 67532 Lock Nut is a fundamental component in ensuring the secure and efficient operation of various engine systems and components.

Conclusion

The Cummins 67532 Lock Nut is a critical component in heavy-duty truck applications, providing secure fastening in environments prone to vibration and dynamic forces. Its key features, including high-strength materials and a design that creates additional friction, ensure durability and reliability. Proper installation and regular maintenance are essential for optimal performance. The lock nut’s compatibility with Cummins engines and its role in various engine systems highlight its importance in ensuring the secure and efficient operation of heavy-duty trucks.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.