This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3907489 O-Ring is a critical component designed to maintain the integrity of seals within commercial truck systems. It plays a significant role in ensuring the operational efficiency and reliability of truck systems by preventing leaks and ensuring proper system function 1.

Basic Concepts of O-Rings

An O-Ring is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create seals in various mechanical systems. It operates by being compressed between two surfaces, creating a seal that prevents the passage of fluids or gases. O-Rings are widely utilized due to their simplicity, effectiveness, and versatility in sealing applications 2.

Purpose of the Cummins 3907489 O-Ring

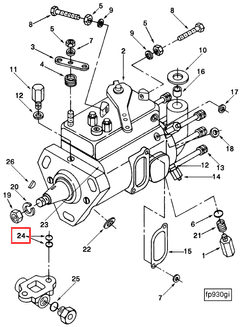

This Cummins part is specifically designed to play a role in the sealing mechanisms of commercial trucks. It is associated with various systems or components within the truck, ensuring that fluids and gases remain contained within their designated pathways. This helps in maintaining the efficiency and performance of the truck’s systems.

Key Features

This part is characterized by its material composition, typically made from durable elastomers that can withstand the operational stresses and environmental conditions encountered in commercial truck applications. Its dimensions and design are tailored to fit specific applications, ensuring a snug fit and effective sealing. The material and design characteristics contribute to its suitability for the intended application, offering resilience against wear and degradation.

Benefits

The Cummins 3907489 O-Ring offers several benefits, including enhanced sealing efficiency, which helps in preventing leaks and maintaining system integrity. Its durability ensures long-term performance under demanding conditions, while its reliability contributes to the overall dependability of truck operations. These attributes make it a valuable component in ensuring the smooth and efficient operation of commercial trucks.

Installation Considerations

When installing the O-Ring, it is important to follow guidelines and best practices to ensure proper function. This includes handling the O-Ring with care to avoid damage, using appropriate lubrication during installation to facilitate seating, and adhering to any specified torque settings to ensure the O-Ring is properly compressed without being overtightened.

Troubleshooting Common Issues

Common issues with O-Rings, such as leaks or failures, can often be traced back to installation errors, material degradation, or operational stresses. Troubleshooting steps may include inspecting the O-Ring for signs of wear or damage, ensuring proper installation techniques were used, and verifying that the O-Ring is compatible with the system’s operational conditions.

Maintenance Tips

Regular maintenance of the Cummins 3907489 O-Ring involves periodic inspections to check for signs of wear, degradation, or damage. Cleaning the O-Ring and its seating surfaces can help prevent contamination-related issues. Replacement guidelines should be followed to ensure that the O-Ring is changed before it reaches the end of its service life, thereby maintaining optimal performance and system integrity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3907489 O-Ring, which is designed to meet the demanding requirements of commercial truck applications.

Conclusion

The Cummins 3907489 O-Ring is a vital component in the maintenance of commercial truck systems, offering durability, reliability, and effective sealing. Proper installation, regular maintenance, and timely replacement are key to ensuring the continued efficiency and performance of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.