This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Suction Connection, identified by part number 213379, is a component manufactured by Cummins, a renowned leader in the production of diesel engines and related technologies. This part plays a role in the lubrication system of heavy-duty trucks, contributing to the efficient operation and longevity of the engine.

Basic Concepts

Oil suction connections are integral to the lubrication systems of engines. They facilitate the flow of oil from the oil pan to the engine’s lubrication points. By maintaining a consistent supply of oil, these connections help reduce friction between moving parts, dissipate heat, and remove contaminants, thereby protecting the engine from wear and damage 1.

Purpose and Function

The primary role of the Oil Suction Connection in a truck’s engine is to ensure the proper lubrication of engine components. It does this by drawing oil from the oil pan and directing it to the engine’s lubrication system. This process is vital for maintaining optimal engine performance, efficiency, and longevity. Proper lubrication reduces friction and wear on engine parts, ensuring smooth operation and preventing premature failure 2.

Key Features

The 213379 Oil Suction Connection is designed with several key features that enhance its performance and reliability. It is constructed from high-quality materials to withstand the harsh conditions within an engine environment. The design of the connection ensures a secure fit and efficient oil flow. Additionally, it may include features such as reinforced seals or corrosion-resistant coatings to further improve its durability and functionality.

Benefits

Utilizing the 213379 Oil Suction Connection offers several benefits. It contributes to improved engine efficiency by ensuring a consistent and reliable oil supply. This consistent lubrication reduces wear and tear on engine components, leading to enhanced overall performance and reliability. Furthermore, by maintaining optimal lubrication, the connection helps extend the engine’s lifespan, providing value and peace of mind to truck operators 3.

Installation and Maintenance

Proper installation and maintenance of the Oil Suction Connection are crucial for ensuring optimal performance and longevity. Installation should follow manufacturer guidelines to ensure a secure and efficient connection. Regular maintenance, including inspection for leaks, cleaning, and timely replacement when necessary, is recommended to prevent issues and ensure the connection continues to function effectively.

Troubleshooting

Common issues with the Oil Suction Connection may include leaks, blockages, or malfunctions. Troubleshooting these problems involves inspecting the connection for signs of damage or wear, checking for proper fit and alignment, and ensuring there are no obstructions in the oil flow path. Addressing these issues promptly can help maintain the efficiency and reliability of the engine’s lubrication system.

Cummins Overview

Cummins is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance automotive components. Their dedication to advancing engine technology ensures that their products, like the 213379 Oil Suction Connection, meet the demanding requirements of heavy-duty applications.

Cummins Oil Suction Connection Part 213379

The Cummins Oil Suction Connection part 213379 is a component designed to facilitate the flow of oil within various engine systems. This part is engineered to ensure a seamless and efficient transfer of oil, which is essential for maintaining engine performance and longevity.

Application in Engine Models

-

V903 Engines

- The V903 engine series, known for its robust design and reliability, incorporates the part 213379 as a key element in its oil management system. This connection ensures that oil is properly suctioned and distributed throughout the engine, supporting critical functions such as lubrication and cooling.

-

Other Cummins Engines

- Beyond the V903 series, the part 213379 is also utilized in various other Cummins engine models. Its design and functionality are tailored to meet the specific requirements of each engine type, ensuring optimal performance across different applications.

Importance of the Oil Suction Connection

The oil suction connection is vital for maintaining the integrity of the engine’s lubrication system. By providing a reliable pathway for oil to travel from the oil reservoir to the engine’s moving parts, this component helps to prevent wear and tear, reduce friction, and maintain the engine’s overall efficiency. Its precise engineering ensures that oil is delivered consistently, even under varying operational conditions, contributing to the engine’s durability and reliability.

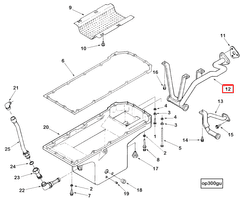

Role of Part 213379 Oil Suction Connection in Engine Systems

The Part 213379 Oil Suction Connection is an integral component in the lubrication system of an engine, ensuring the smooth operation of various engine components. This part is specifically designed to interface with the oil pan and facilitate the efficient suction of oil.

Interaction with the Oil Pan

The Oil Suction Connection is mounted on the oil pan, which serves as the reservoir for the engine’s lubricant. The primary function of this connection is to draw oil from the pan and transport it to the oil pump. This process is essential for maintaining a consistent supply of oil to the engine’s moving parts, thereby reducing friction and wear.

Ensuring Consistent Oil Flow

As the engine operates, the Oil Suction Connection plays a pivotal role in ensuring a steady flow of oil to the pump. This consistent flow is vital for the pump to effectively circulate oil through the engine’s lubrication circuits. The connection must be securely fitted to prevent any leaks or disruptions in the oil supply, which could lead to inadequate lubrication and potential engine damage.

Integration with the Lubrication System

Once the oil is suctioned from the pan, it travels through the Oil Suction Connection to the oil pump. The pump then pressurizes the oil and distributes it to critical engine components such as the crankshaft, camshaft, pistons, and bearings. This lubrication is essential for the longevity and performance of these parts, as it minimizes metal-to-metal contact and heat generation.

Maintenance and Inspection

Regular inspection and maintenance of the Oil Suction Connection are necessary to ensure its proper function. Any signs of wear, corrosion, or damage should be addressed promptly to maintain the integrity of the lubrication system. Proper sealing and fitting of the connection are also crucial to prevent oil leaks, which can lead to a drop in oil pressure and compromised engine performance.

Conclusion

In summary, the Part 213379 Oil Suction Connection is a key component in the engine’s lubrication system, working in tandem with the oil pan to ensure a reliable and consistent supply of oil to the engine’s vital components. Its role in maintaining engine performance and longevity underscores the importance of proper installation, maintenance, and timely troubleshooting to ensure optimal engine operation.

-

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Zhan, Q., Eben, S., & Deng, L.K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.