216354

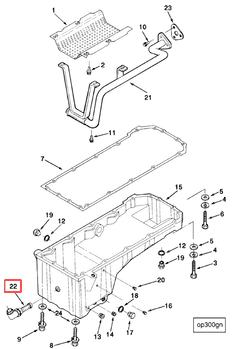

Oil Suction Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 216354 Oil Suction Connection is a critical component in commercial truck engines, designed to facilitate the efficient transfer of oil from the oil pan to the engine’s lubrication system 1. This part ensures a consistent supply of oil, which is essential for engine operation and longevity.

Basic Concepts of Oil Suction Connection

Oil suction connections are vital for the engine system, acting as conduits for oil drawn from the oil pan and circulated throughout the engine 2. These connections create a pathway for the oil pump to suction oil, which is then distributed to various engine components. Proper lubrication is crucial for reducing friction, wear, and heat generation within the engine.

Purpose and Function

The Cummins 216354 Oil Suction Connection is designed to enhance the lubrication process in a truck’s engine system. It provides a reliable connection point for the oil pump to draw oil from the oil pan, contributing to the engine’s overall operation and efficiency 3. This part ensures that the engine maintains optimal lubrication levels, which is vital for its performance and durability.

Key Features

The Cummins 216354 Oil Suction Connection is constructed from high-quality materials to withstand the pressures and temperatures within the engine compartment. Its design includes features that ensure a secure fit and efficient oil flow, contributing to the part’s reliability and longevity.

Benefits

The use of the Cummins 216354 Oil Suction Connection offers several advantages. It improves engine lubrication by ensuring a consistent and efficient oil supply to the engine components. This enhanced lubrication contributes to reduced wear and tear, potentially extending the engine’s lifespan. Additionally, efficient oil management can lead to cost savings by minimizing the need for frequent oil changes and reducing the risk of engine damage due to inadequate lubrication.

Installation and Compatibility

Proper installation of the Cummins 216354 Oil Suction Connection is crucial for its effective operation. It is designed to be compatible with specific engine models and configurations, ensuring a seamless integration into the engine system. Installation guidelines should be followed to ensure a secure fit and optimal performance. Compatibility information is available to assist in selecting the correct part for your engine.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 216354 Oil Suction Connection is recommended to ensure its optimal performance. This includes regular inspections for signs of wear or damage and ensuring that all connections are secure. Troubleshooting common issues, such as leaks or inefficient oil flow, may involve checking for proper installation, inspecting for damage, and ensuring that all components are functioning correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for manufacturing reliable and high-performance automotive components. Their products are known for their durability, efficiency, and contribution to the overall performance of vehicles in which they are installed.

Conclusion

The Cummins 216354 Oil Suction Connection is a vital component in the engine’s lubrication system, ensuring a consistent and efficient supply of oil to the engine components. Its design and construction contribute to the engine’s performance, durability, and cost-effectiveness. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.